Figure 17 shows an example of a skew chisel.

Figure 17. Skew chisel.

•Scrapers—Mainly used where access for other tools is limited, such as hollowing oper- ations. This is a flat, double-ground tool that comes in a variety of profiles (Round Nose, Spear Point, Square Nose, etc.) to match many different contours. Figure 18 shows an example of a round nose scraper.

Figure 18. Round nose scraper.

•Parting Tools—Used for sizing and cut- ting off work. This is a flat tool with a sharp pointed nose that may be single- or double- ground. Figure 19 shows an example of a parting tool.

Figure 19. Parting tool.

•Specialty Tools—These are the unique, special function tools to aid in hollowing, bowl making, cutting profiles, etc. The Swan Neck Hollowing Tool shown on Page 22 is a good example of a specialty tool.

Spindle Turning

Spindle turning (Figure 20) is the operation per- formed when a workpiece is mounted between the headstock and the tailstock.

Figure 20. Typical spindle turning operation.

To set up a spindle turning operation:

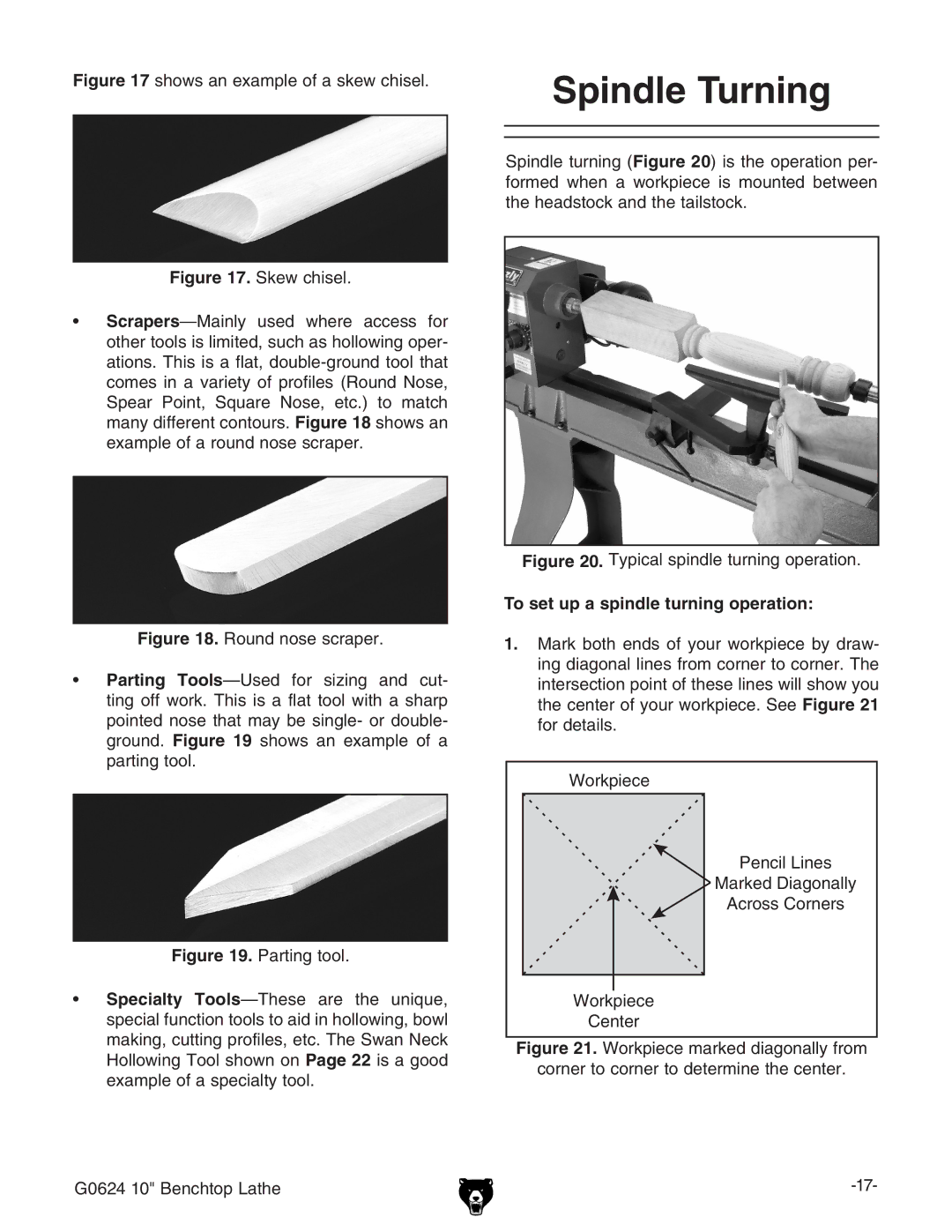

1.Mark both ends of your workpiece by draw- ing diagonal lines from corner to corner. The intersection point of these lines will show you the center of your workpiece. See Figure 21 for details.

���������

������������

�����������������

��������������

���������

������

Figure 21. Workpiece marked diagonally from

corner to corner to determine the center.

G0624 10" Benchtop Lathe |