•Turn the lathe OFF immediately if the workpiece vibrates excessively. Check to make sure the workpiece is centered and balanced. Remove the workpiece and trim excess waste off corners with a bandsaw or table saw to reduce vibration. Make sure workpiece is securely attached in the setup.

Faceplate Turning

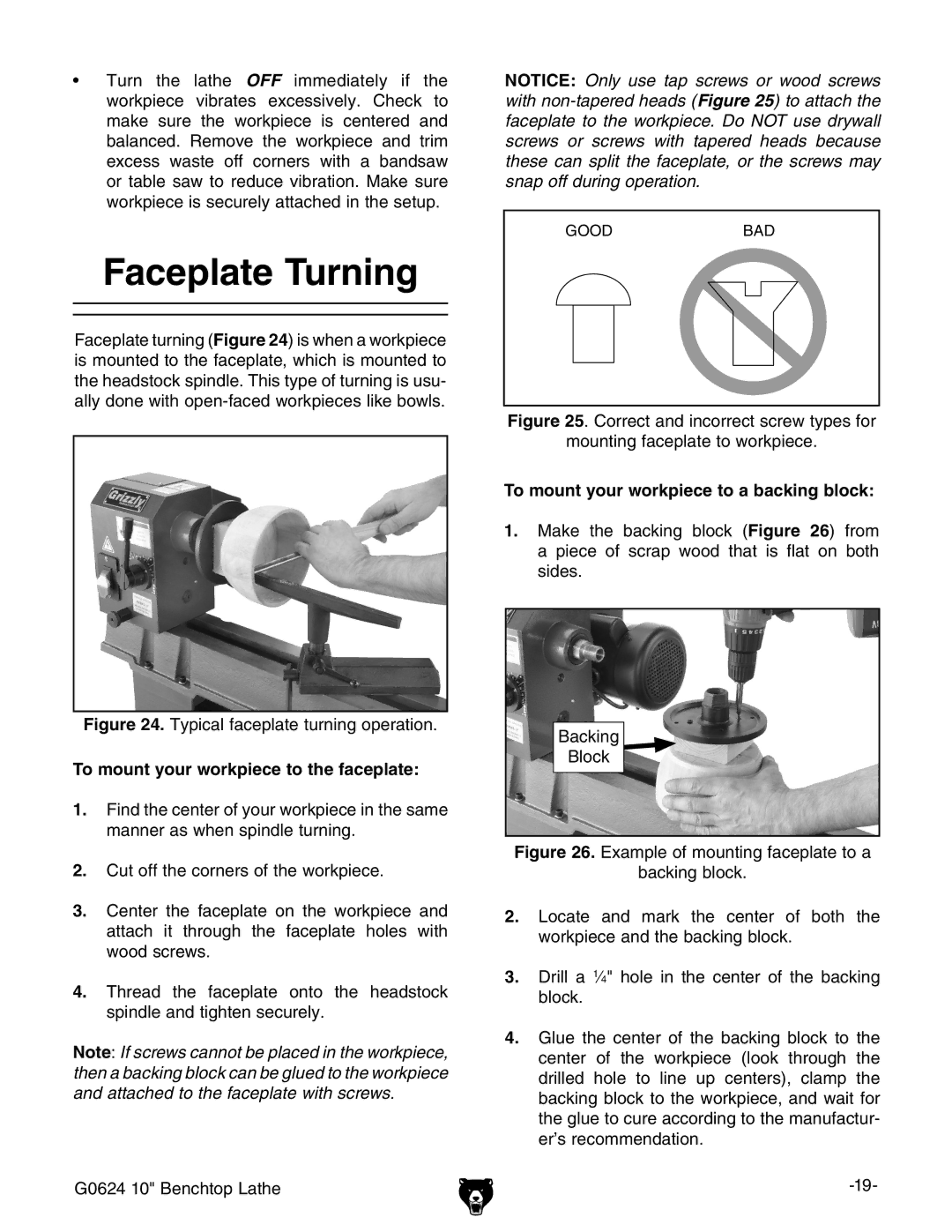

Faceplate turning (Figure 24) is when a workpiece is mounted to the faceplate, which is mounted to the headstock spindle. This type of turning is usu- ally done with

Figure 24. Typical faceplate turning operation.

To mount your workpiece to the faceplate:

1.Find the center of your workpiece in the same manner as when spindle turning.

2.Cut off the corners of the workpiece.

3.Center the faceplate on the workpiece and attach it through the faceplate holes with wood screws.

4.Thread the faceplate onto the headstock spindle and tighten securely.

Note: If screws cannot be placed in the workpiece, then a backing block can be glued to the workpiece and attached to the faceplate with screws.

G0624 10" Benchtop Lathe

NOTICE: Only use tap screws or wood screws with

��������

Figure 25. Correct and incorrect screw types for

mounting faceplate to workpiece.

To mount your workpiece to a backing block:

1.Make the backing block (Figure 26) from a piece of scrap wood that is flat on both sides.

Backing

Block