SECTION 4: OPERATIONS

Operation Safety |

| Blade Speed |

|

|

|

|

|

|

Damage to your eyes, lungs, and ears could result from using this machine without proper protective gear. Always wear safety glasses, a respirator, and hearing protection when operating this machine.

Loose hair and cloth-

ing could get caught in

![]() machinery and cause seri-

machinery and cause seri-

ous personal injury. Keep

loose clothing and long

hair away from moving machinery.

NOTICE

If you have never used this type of machine or equipment before, WE STRONGLY REC- OMMEND that you read books, trade maga- zines, or get formal training before begin- ning any projects. Regardless of the con- tent in this section, Grizzly Industrial will not be held liable for accidents caused by lack of training.

Electrocution Hazard. The motor and switch on this bandsaw are not protected against liquids. Do not use cutting fluids with this bandsaw. Serious injury could occur.

The Model G1010 has these three blade speeds: 80, 120, and 220 FPM.

To change blade speeds:

1.UNPLUG THE BANDSAW!

2.Determine the best speed for your cut. The table in Figure 27 is provided as a rough guideline. Material thickness and the type of blade used will factor into FPM selection.

Material | Feet Per Minute |

| (FPM) |

|

|

Aluminum | 250 |

|

|

Plastics | 800 |

|

|

Brass (soft) | 500 |

|

|

Carbon Tool Steel | |

|

|

Cast Iron | |

|

|

Cold Rolled Steel | |

|

|

High Speed Steel | |

Malleable Iron | |

Hard Rubber |

Figure 27. Blade speed table.

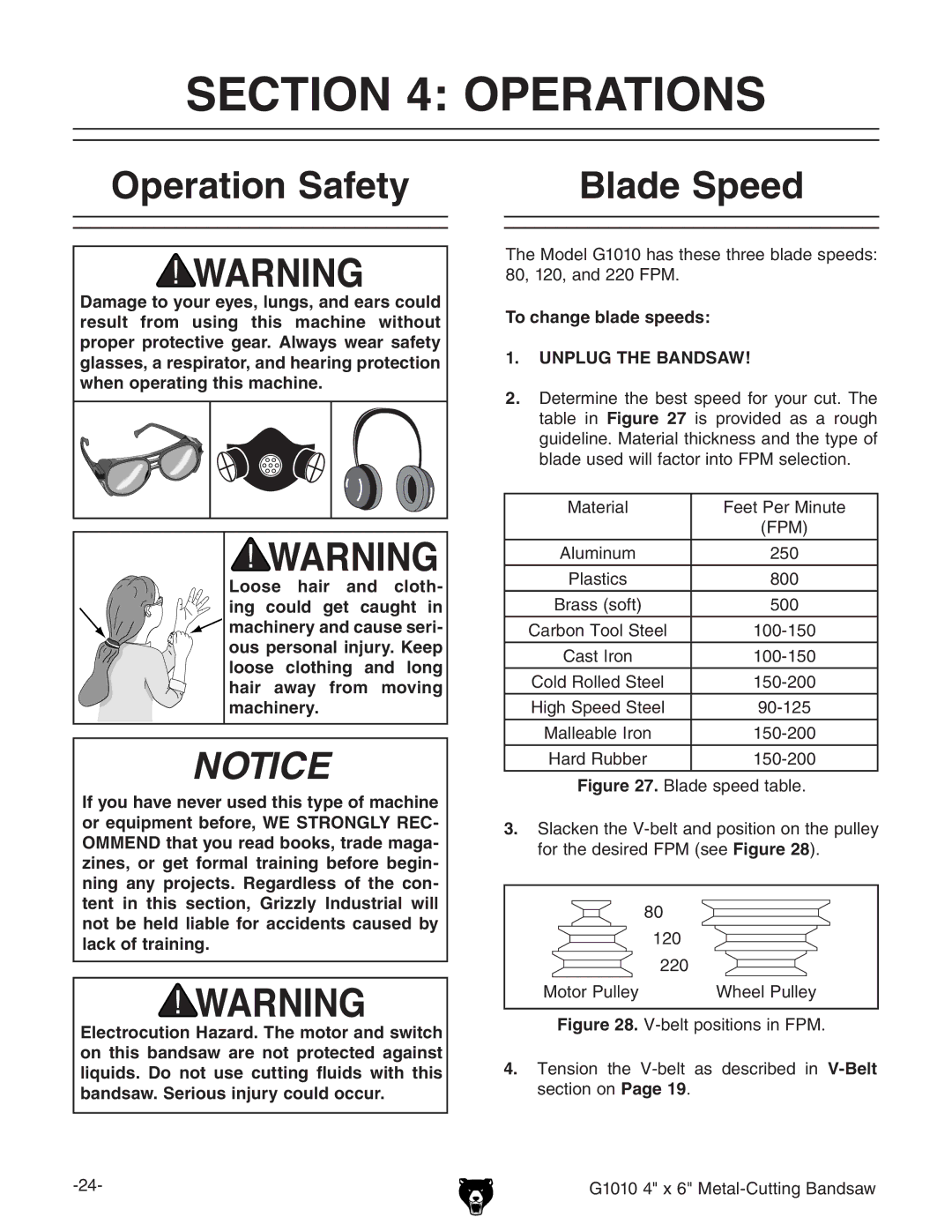

3.Slacken the V-belt and position on the pulley for the desired FPM (see Figure 28).

80

| 120 |

| 220 |

Motor Pulley | Wheel Pulley |