Blade Guide

Bearings

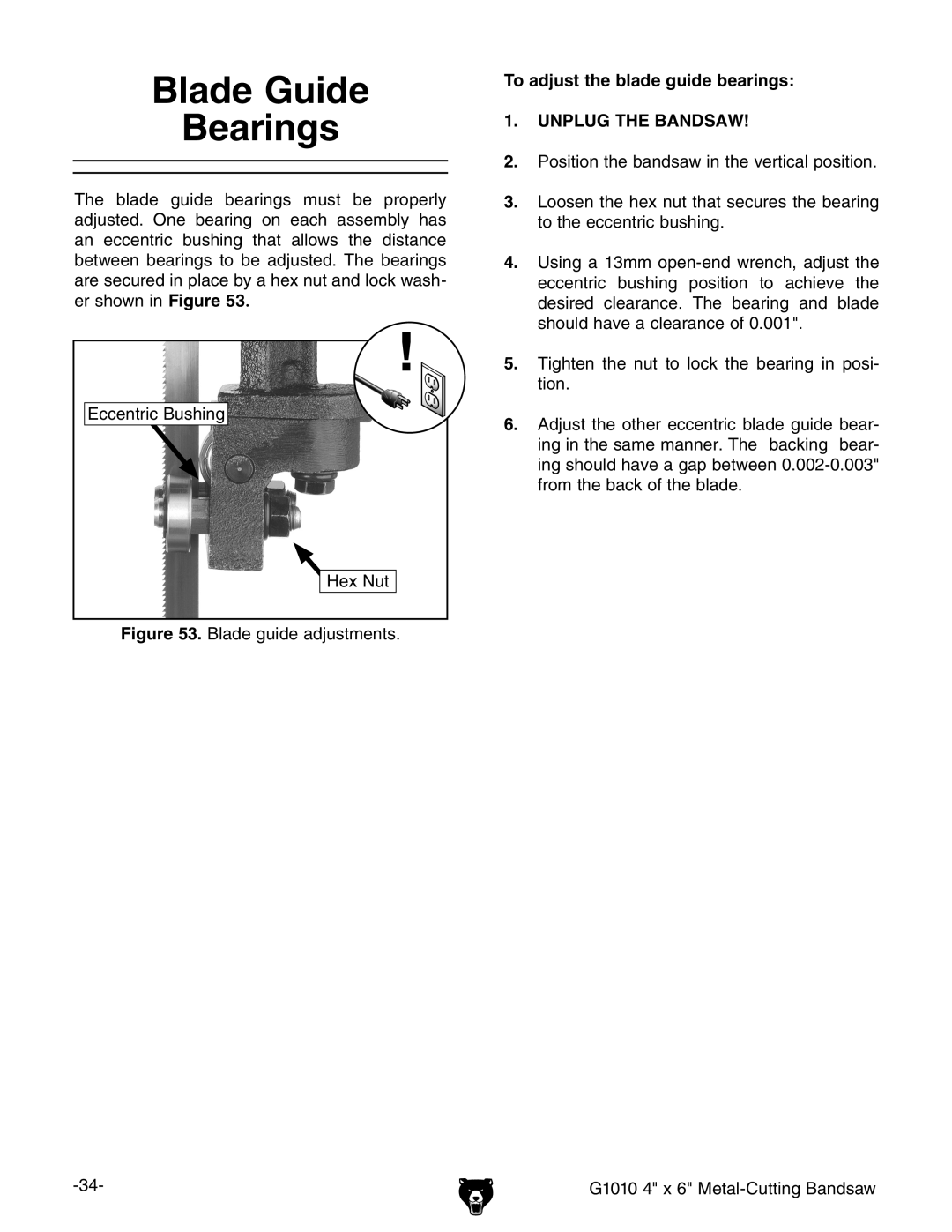

The blade guide bearings must be properly adjusted. One bearing on each assembly has an eccentric bushing that allows the distance between bearings to be adjusted. The bearings are secured in place by a hex nut and lock wash- er shown in Figure 53.

Eccentric Bushing |

Hex Nut |

Figure 53. Blade guide adjustments.

To adjust the blade guide bearings:

1.UNPLUG THE BANDSAW!

2.Position the bandsaw in the vertical position.

3.Loosen the hex nut that secures the bearing to the eccentric bushing.

4.Using a 13mm

5.Tighten the nut to lock the bearing in posi- tion.

6.Adjust the other eccentric blade guide bear- ing in the same manner. The backing bear- ing should have a gap between

G1010 4" x 6" |