Lubrication

The Model G1021X features

Proper lubrication of other planer components are essential for long life and

Always disconnect power to the machine before lubricating! Failure to do this may result in serious personal injury.

Columns/Lead Screws: The four columns should be lubricated weekly with SAE 30W oil. Unfasten dust covers to gain access. The four lead screws should be lubricated with general purpose grease once a month.

Worm Gear: The worm gear should be inspected monthly and lubricated with general purpose grease when needed. Remove the worm gear box to inspect. See parts diagram for location.

Chain: The table height adjustment chain should be inspected monthly and lubricated with general purpose grease when needed.

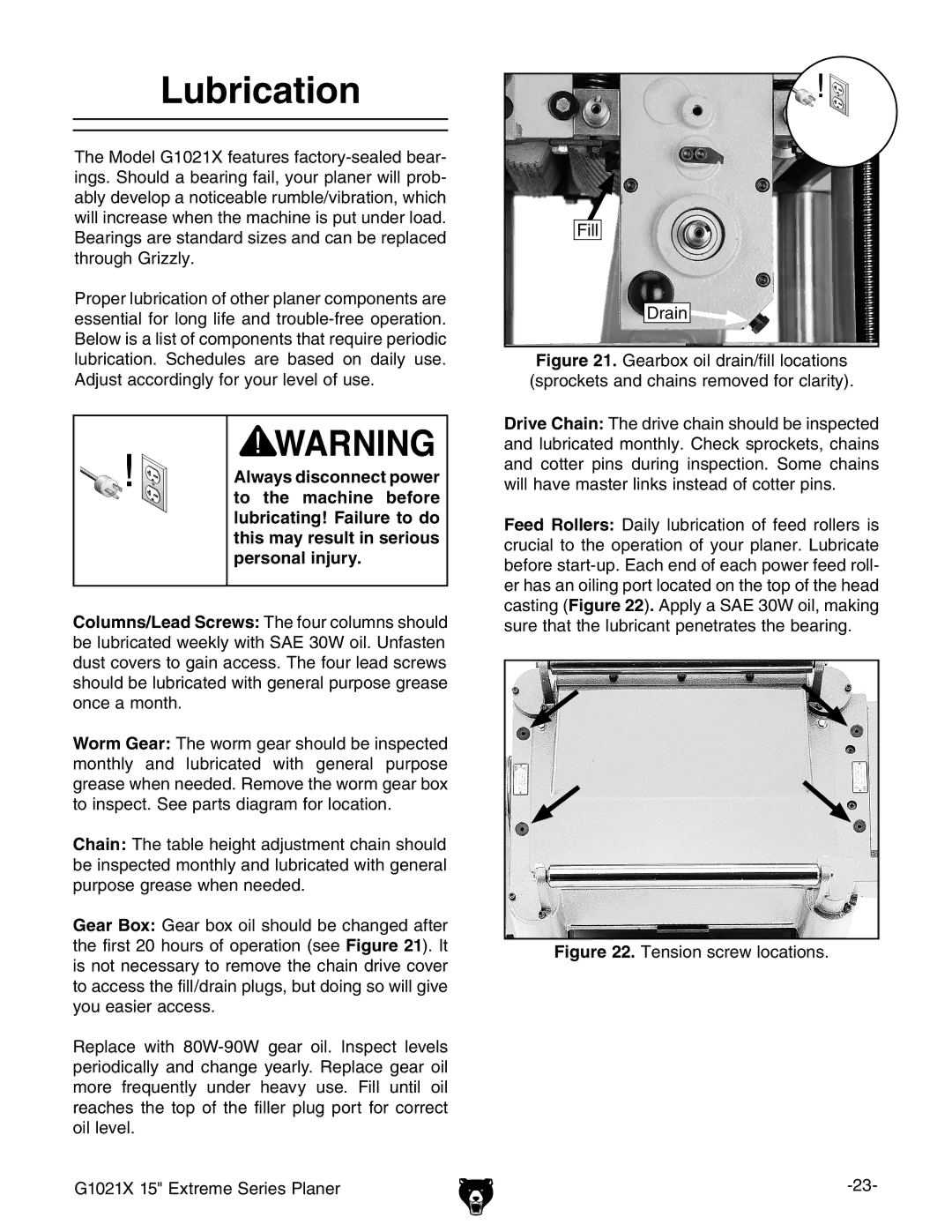

Gear Box: Gear box oil should be changed after the first 20 hours of operation (see Figure 21). It is not necessary to remove the chain drive cover to access the fill/drain plugs, but doing so will give you easier access.

Replace with

G1021X 15" Extreme Series Planer

Fill |

Drain |