Anti-Kickback Fingers

The Model G1021X provides an

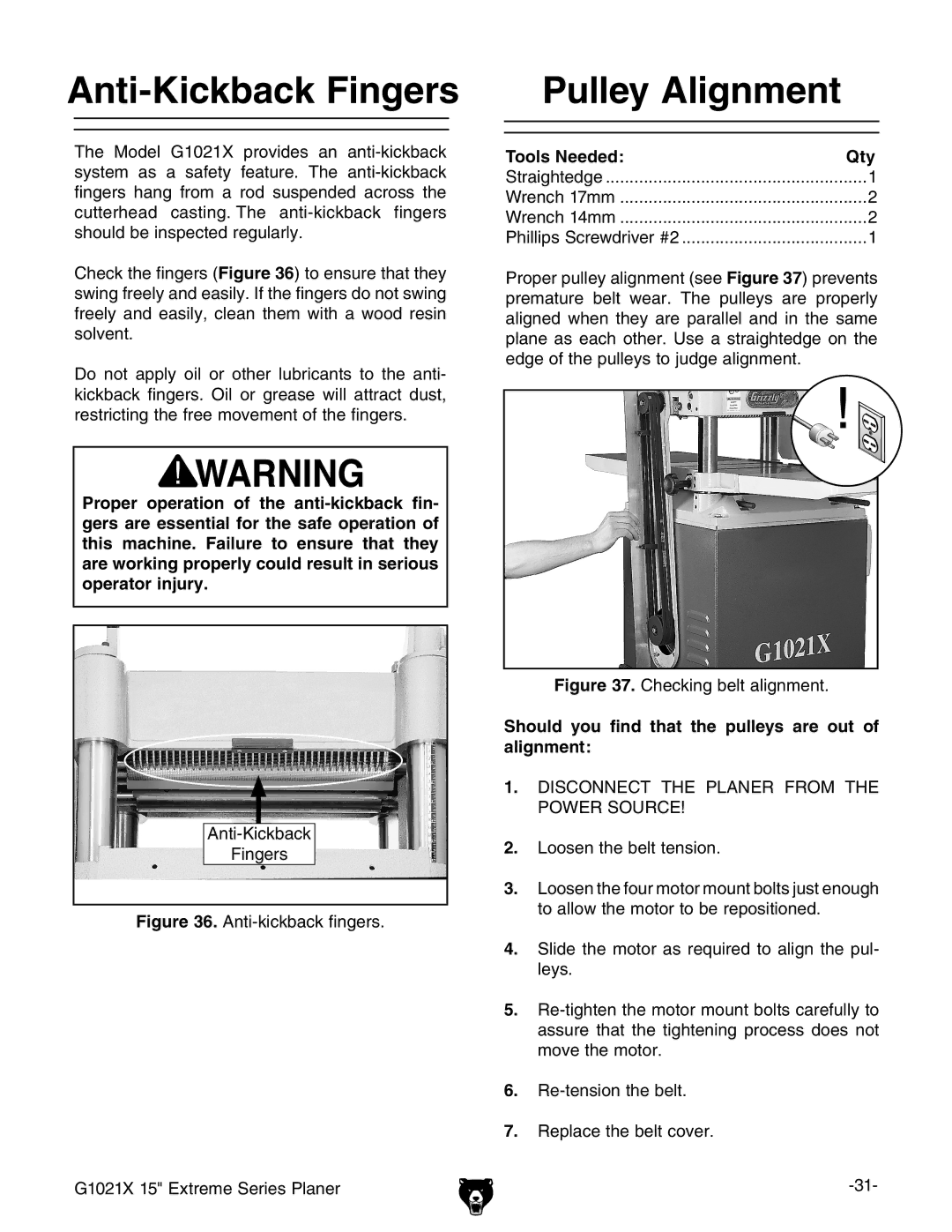

Check the fingers (Figure 36) to ensure that they swing freely and easily. If the fingers do not swing freely and easily, clean them with a wood resin solvent.

Do not apply oil or other lubricants to the anti- kickback fingers. Oil or grease will attract dust, restricting the free movement of the fingers.

Proper operation of the

Fingers

Figure 36. Anti-kickback fingers.

G1021X 15" Extreme Series Planer

Pulley Alignment

Tools Needed: | Qty |

Straightedge | 1 |

Wrench 17mm | 2 |

Wrench 14mm | 2 |

Phillips Screwdriver #2 | 1 |

Proper pulley alignment (see Figure 37) prevents premature belt wear. The pulleys are properly aligned when they are parallel and in the same plane as each other. Use a straightedge on the edge of the pulleys to judge alignment.

Figure 37. Checking belt alignment.

Should you find that the pulleys are out of alignment:

1.DISCONNECT THE PLANER FROM THE POWER SOURCE!

2.Loosen the belt tension.

3.Loosen the four motor mount bolts just enough to allow the motor to be repositioned.

4.Slide the motor as required to align the pul- leys.

5.

6.

7.Replace the belt cover.