Wheel Alignment

The upper wheel can be adjusted to correct for any deviation in parallelism. Although this has been set at the factory, it is a good idea to check it occasionally to assure good and proper opera- tion of your bandsaw. To adjust the wheel paral- lelism:

1.Open the top and bottom covers.

2.Measure the distance the bottom wheel is from the bandsaw frame, front to back. Usually the Lower wheel will be slightly at an angle to the bandsaw frame. Make note which way the wheel is skewed and by how much.

3.Now measure the top wheel, front to back. Ideally, you want the top wheel to match the angle at which the bottom wheel is set. For example: if the you determine the bottom wheel is tapered to the front by 1⁄16'', the top wheel should be adjusted so it is tapered in the same direction by the same amount.

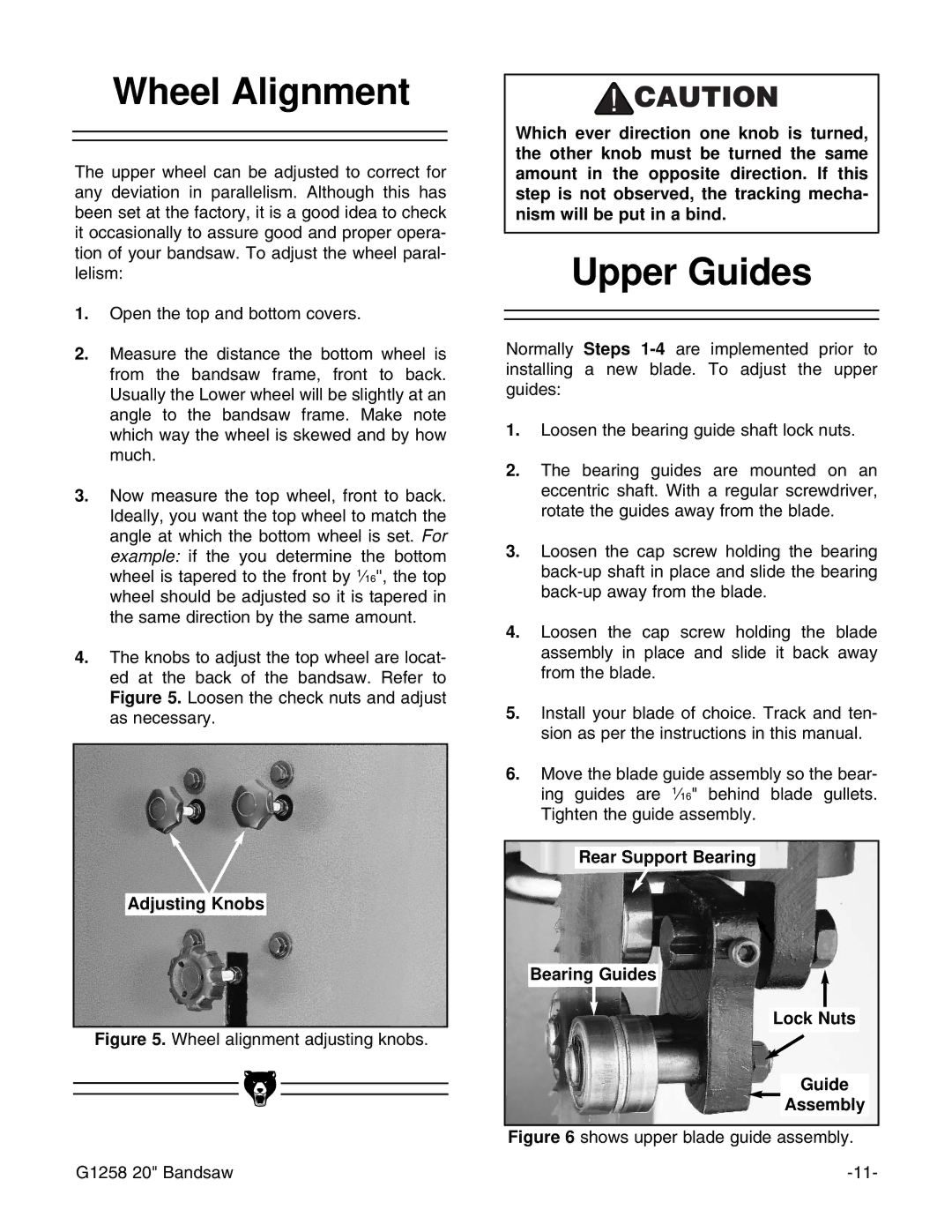

4.The knobs to adjust the top wheel are locat- ed at the back of the bandsaw. Refer to Figure 5. Loosen the check nuts and adjust as necessary.

Adjusting Knobs

Figure 5. Wheel alignment adjusting knobs.

G1258 20" Bandsaw

Which ever direction one knob is turned, the other knob must be turned the same amount in the opposite direction. If this step is not observed, the tracking mecha- nism will be put in a bind.

Upper Guides

Normally Steps

1.Loosen the bearing guide shaft lock nuts.

2.The bearing guides are mounted on an eccentric shaft. With a regular screwdriver, rotate the guides away from the blade.

3.Loosen the cap screw holding the bearing

4.Loosen the cap screw holding the blade assembly in place and slide it back away from the blade.

5.Install your blade of choice. Track and ten- sion as per the instructions in this manual.

6.Move the blade guide assembly so the bear- ing guides are 1⁄16" behind blade gullets. Tighten the guide assembly.

Rear Support Bearing

Bearing Guides

Lock Nuts

Guide