Follow Rest

The follow rest is normally used with small diam- eter stock to prevent the workpiece from “spring- ing” under pressure from the turning tool. To install the follow rest:

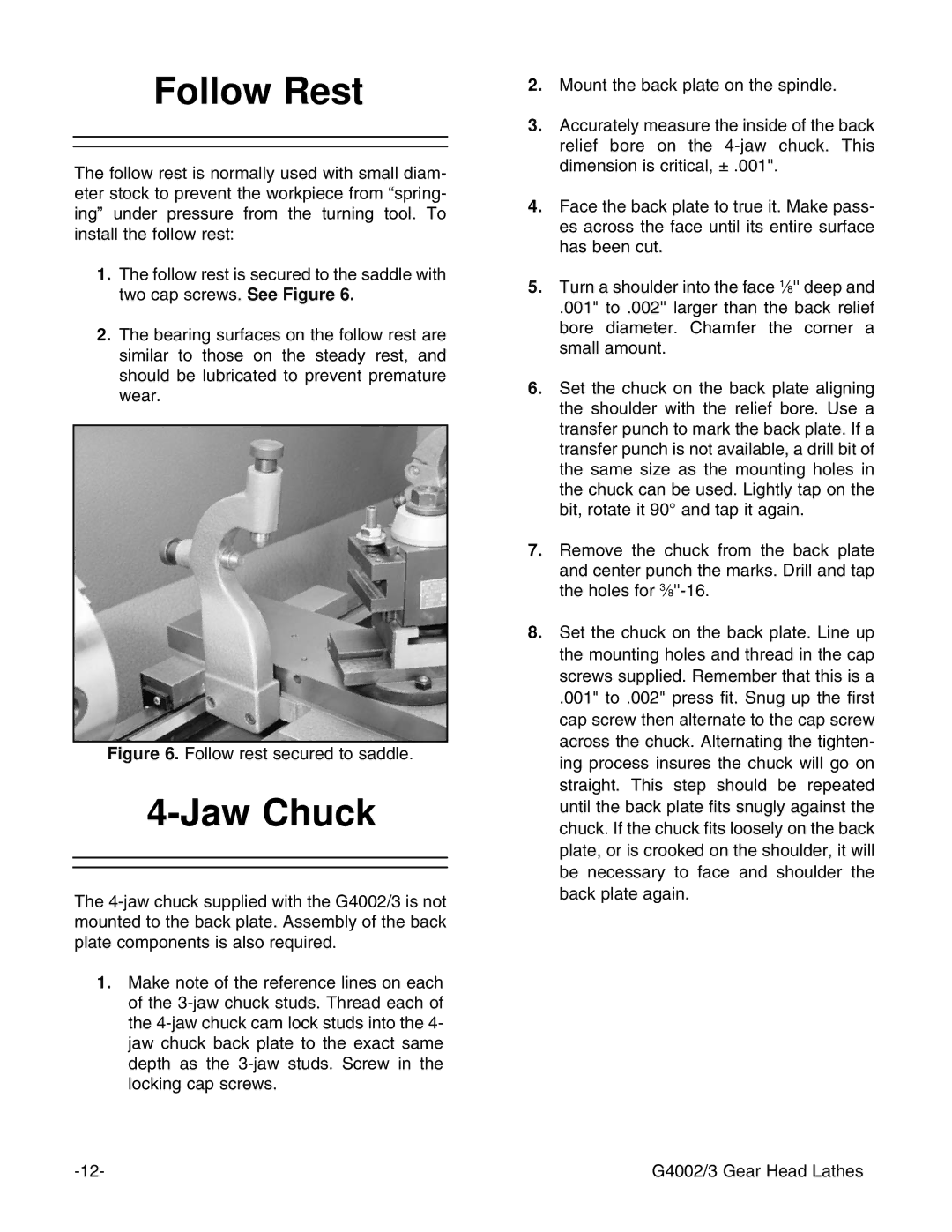

1.The follow rest is secured to the saddle with two cap screws. See Figure 6.

2.The bearing surfaces on the follow rest are similar to those on the steady rest, and should be lubricated to prevent premature wear.

Figure 6. Follow rest secured to saddle.

4-Jaw Chuck

The

1.Make note of the reference lines on each of the

2.Mount the back plate on the spindle.

3.Accurately measure the inside of the back relief bore on the

4.Face the back plate to true it. Make pass- es across the face until its entire surface has been cut.

5.Turn a shoulder into the face 1⁄8'' deep and

.001" to .002'' larger than the back relief bore diameter. Chamfer the corner a small amount.

6.Set the chuck on the back plate aligning the shoulder with the relief bore. Use a transfer punch to mark the back plate. If a transfer punch is not available, a drill bit of the same size as the mounting holes in the chuck can be used. Lightly tap on the bit, rotate it 90° and tap it again.

7.Remove the chuck from the back plate and center punch the marks. Drill and tap the holes for

8.Set the chuck on the back plate. Line up the mounting holes and thread in the cap screws supplied. Remember that this is a

.001" to .002" press fit. Snug up the first cap screw then alternate to the cap screw across the chuck. Alternating the tighten- ing process insures the chuck will go on straight. This step should be repeated until the back plate fits snugly against the chuck. If the chuck fits loosely on the back plate, or is crooked on the shoulder, it will be necessary to face and shoulder the back plate again.

G4002/3 Gear Head Lathes |