Slides and Ways - Apply oil to the ways and slides after each use. Wipe the ways with a clean rag prior to lubrication to ensure that no grime is carried along with your lubricant into

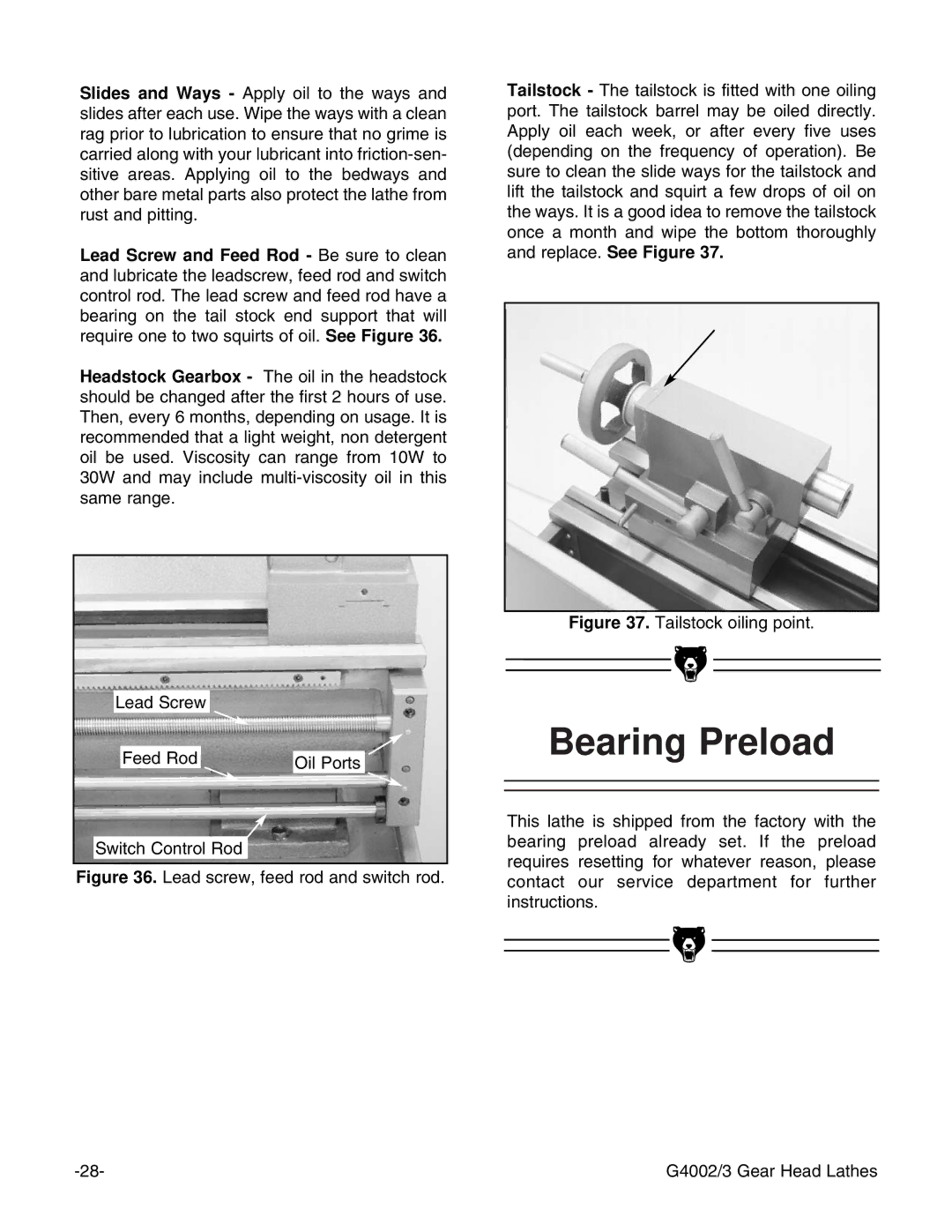

Lead Screw and Feed Rod - Be sure to clean and lubricate the leadscrew, feed rod and switch control rod. The lead screw and feed rod have a bearing on the tail stock end support that will require one to two squirts of oil. See Figure 36.

Headstock Gearbox - The oil in the headstock should be changed after the first 2 hours of use. Then, every 6 months, depending on usage. It is recommended that a light weight, non detergent oil be used. Viscosity can range from 10W to 30W and may include

Lead Screw

Feed Rod | Oil Ports |

|

Switch Control Rod

Figure 36. Lead screw, feed rod and switch rod.

Tailstock - The tailstock is fitted with one oiling port. The tailstock barrel may be oiled directly. Apply oil each week, or after every five uses (depending on the frequency of operation). Be sure to clean the slide ways for the tailstock and lift the tailstock and squirt a few drops of oil on the ways. It is a good idea to remove the tailstock once a month and wipe the bottom thoroughly and replace. See Figure 37.

Figure 37. Tailstock oiling point.

Bearing Preload

This lathe is shipped from the factory with the bearing preload already set. If the preload requires resetting for whatever reason, please contact our service department for further instructions.

|

|

|

|

|

|

|

|

|

|

|

|

G4002/3 Gear Head Lathes | |||