SECTION 7: MAINTENANCE

ALWAYS disconnect the electric power to the machine before servicing. NEVER lubri- cate your lathe while it is running.

Lubrication

Your Model G4002/3 will function best when it is clean and well lubricated. Take the time to wipe down and oil the machine after use. We recom- mend using ISO 68 or SAE 20W

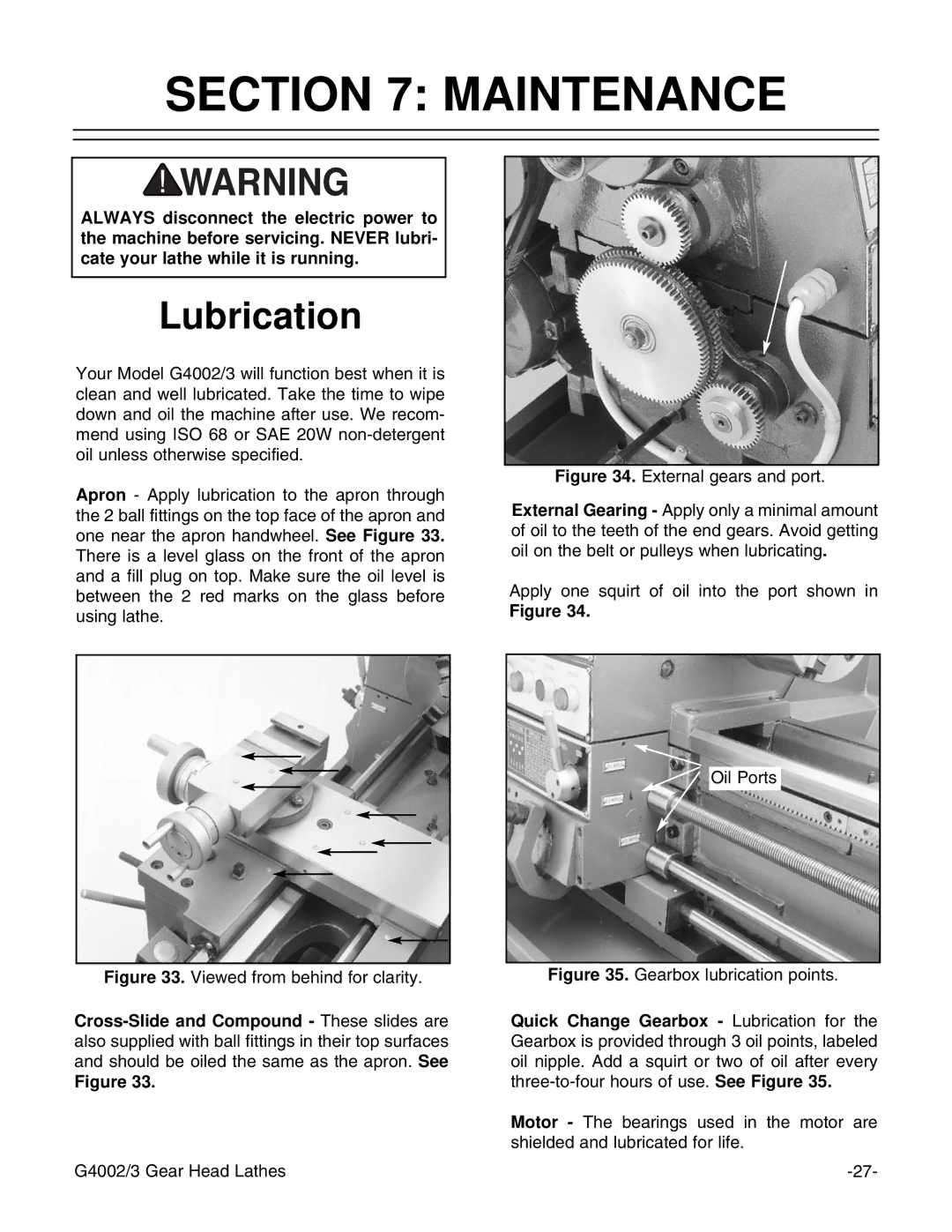

Apron - Apply lubrication to the apron through the 2 ball fittings on the top face of the apron and one near the apron handwheel. See Figure 33. There is a level glass on the front of the apron and a fill plug on top. Make sure the oil level is between the 2 red marks on the glass before using lathe.

Figure 33. Viewed from behind for clarity.

Cross-Slide and Compound - These slides are also supplied with ball fittings in their top surfaces and should be oiled the same as the apron. See

Figure 33.

G4002/3 Gear Head Lathes

Figure 34. External gears and port.

External Gearing - Apply only a minimal amount of oil to the teeth of the end gears. Avoid getting oil on the belt or pulleys when lubricating.

Apply one squirt of oil into the port shown in

Figure 34.