SECTION 6: OPERATIONS

Test Run

Once assembly is complete and adjustments are done to your satisfaction, you are ready to test the machine.

Turn on the power supply at the main panel. Lift the toggle switch to its ON position. Make sure that your finger is poised to flip the toggle to OFF, just in case there’s a problem. The table saw should run smoothly, with little or no vibration or rubbing noises. Strange or unnatural noises should be investigated and corrected before oper- ating the machine further.

DO NOT attempt to investigate or adjust the machine while it is running. Wait until the machine is turned off, unplugged and all working parts have come to a rest before you do anything.

Kickback Causes

There are numerous possible problems that may occur with a tablesaw, but the most frequent avoidable danger is kickback. There are three primary reasons for kickback from any tool with a circular blade:

1.The workpiece rides up onto the blade, set- ting up the teeth to fling it back.

2.The workpiece is pinched between the blade and the fence.

3.

Items 1 and 2 are prevalent in ripping operations, while item 3 can occur during ripping or crosscutting.

G5045 10'' Bench Top Table Saw

Always observe these steps to prevent the possi- bility of kickback occurring:

1.Always use the splitter and guard.

2.Make sure fence is correctly adjusted, with the back exactly parallel to the front or slightly (less than .01”) wider.

3.Use featherboards to keep material being ripped tight to the fence.

4.Always pass

5.Never reach over a running blade.

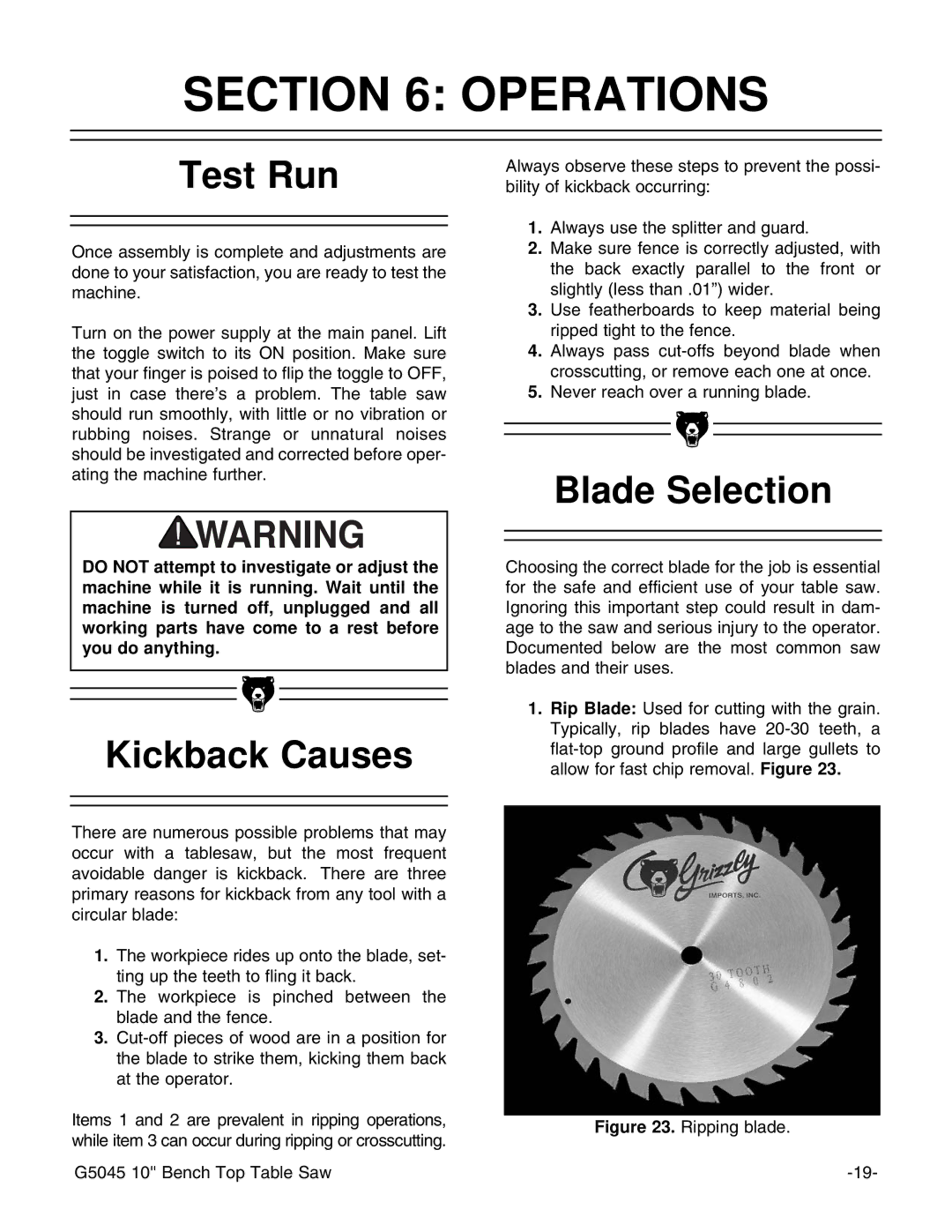

Blade Selection

Choosing the correct blade for the job is essential for the safe and efficient use of your table saw. Ignoring this important step could result in dam- age to the saw and serious injury to the operator. Documented below are the most common saw blades and their uses.

1.Rip Blade: Used for cutting with the grain. Typically, rip blades have