SECTION 5: ADJUSTMENTS

Adjusting the Belt

All

! | Disconnect power to the | |||

machine when perform- | ||||

ing | any | maintenance, | ||

| assembly | or | adjust- | |

| ments. Failure to do this | |||

| may | result in | serious | |

| personal injury. |

| ||

Keep loose clothing rolled up and out of the way of machinery and keep hair pulled back.

Wear safety glasses dur- ing the entire adjustment process. Failure to com- ply may result in serious personal injury.

A slipping belt wastes power, causes control problems and wears the belt out prematurely. You should be able to deflect the belt 1⁄2" to 3⁄4" with moderate finger pressure. The belt will slip if too loose and squeal or cause vibration if too tight.

If the belt is too loose, or too tight:

1.Loosen the bolts around the motor base as shown in Figure 13.

Figure 13. Loosening motor mount bolts.

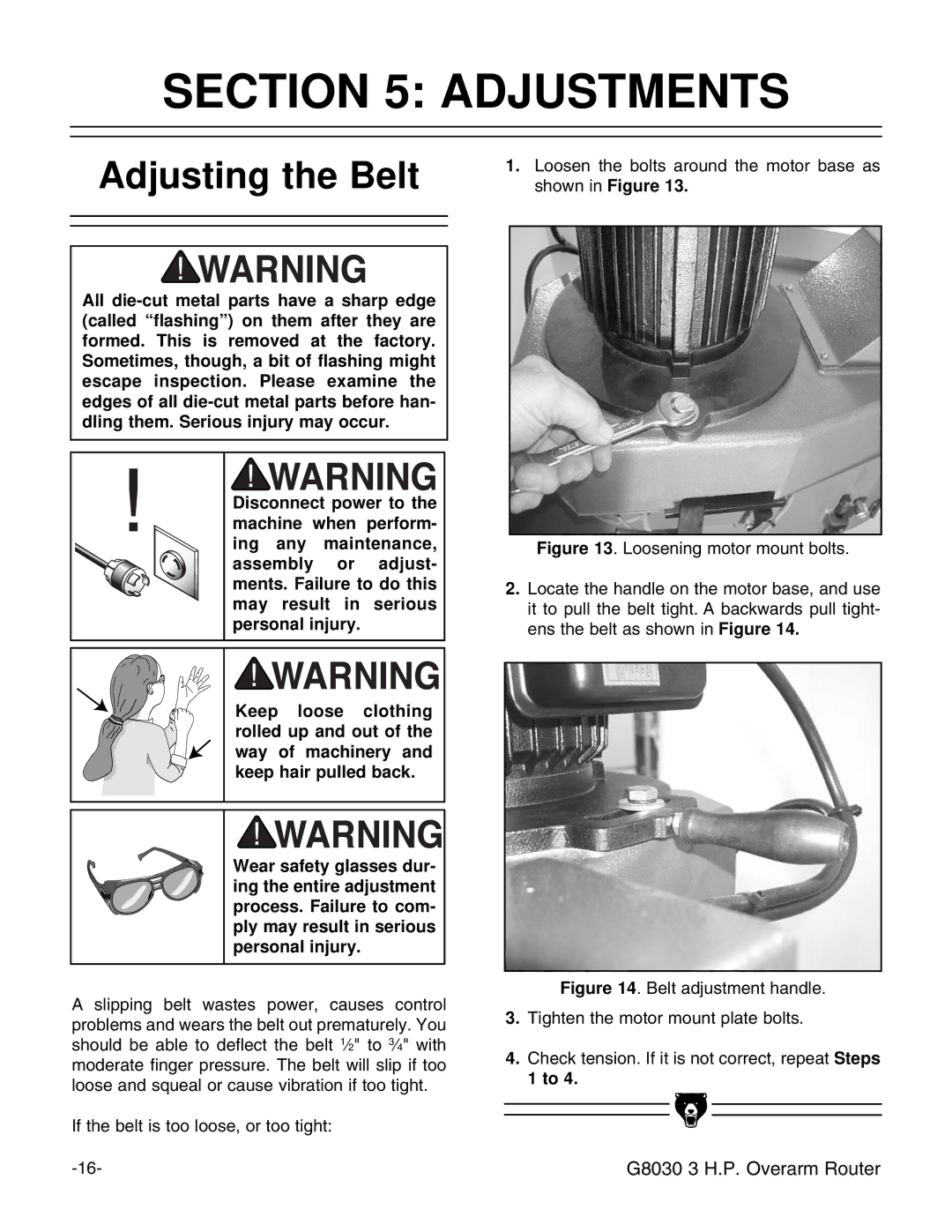

2.Locate the handle on the motor base, and use it to pull the belt tight. A backwards pull tight- ens the belt as shown in Figure 14.

Figure 14. Belt adjustment handle.

3.Tighten the motor mount plate bolts.

4.Check tension. If it is not correct, repeat Steps 1 to 4.

G8030 3 H.P. Overarm Router