Straight Routing | Dust Control | |

|

|

|

|

|

|

The overarm router can also be used to do straight routing procedures as well. The overarm router comes with a

1.Set the fence to the position required for the routing application. Tighten down the bolts securely so the fence will not move accident- ly.

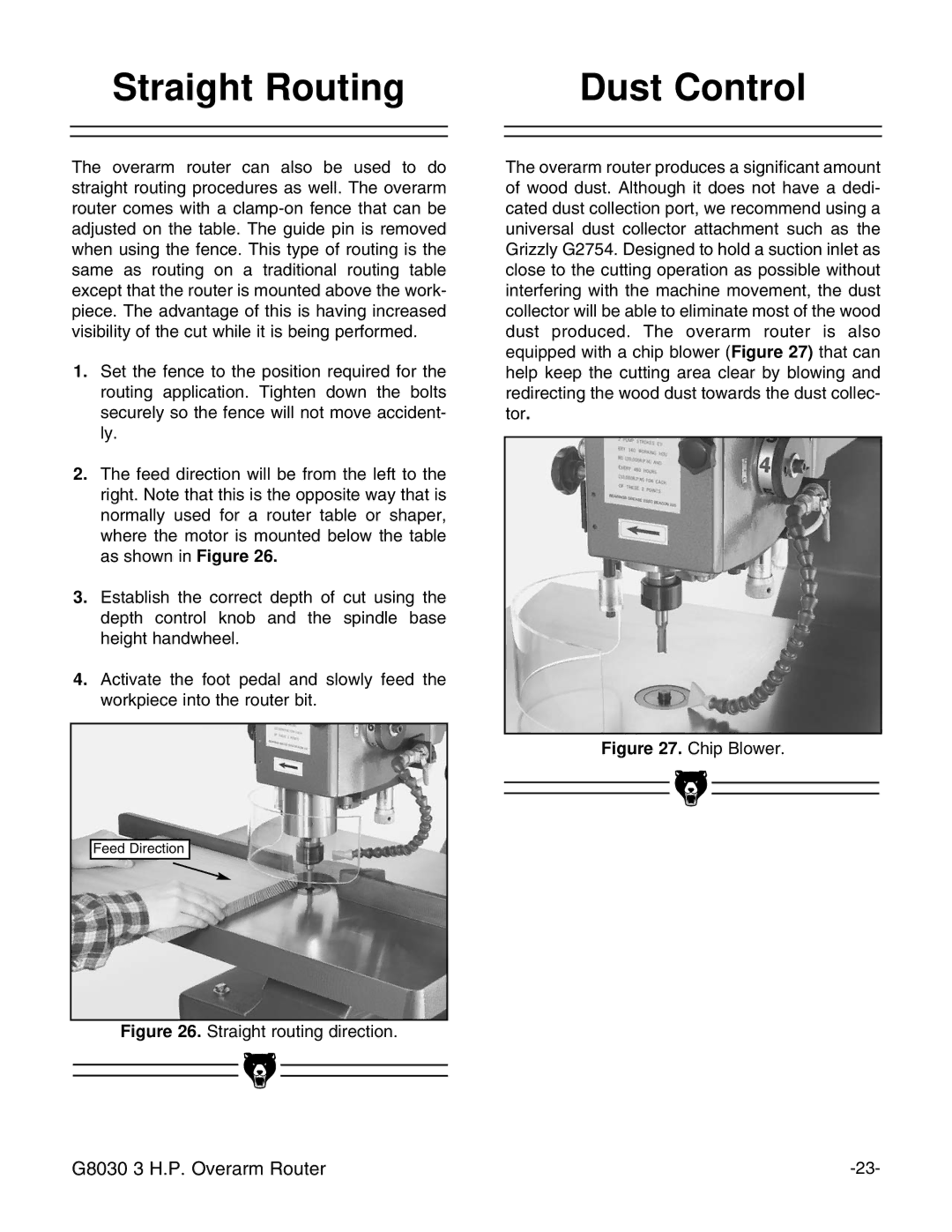

2.The feed direction will be from the left to the right. Note that this is the opposite way that is normally used for a router table or shaper, where the motor is mounted below the table as shown in Figure 26.

3.Establish the correct depth of cut using the depth control knob and the spindle base height handwheel.

4.Activate the foot pedal and slowly feed the workpiece into the router bit.

Feed Direction

Figure 26. Straight routing direction.

The overarm router produces a significant amount of wood dust. Although it does not have a dedi- cated dust collection port, we recommend using a universal dust collector attachment such as the Grizzly G2754. Designed to hold a suction inlet as close to the cutting operation as possible without interfering with the machine movement, the dust collector will be able to eliminate most of the wood dust produced. The overarm router is also equipped with a chip blower (Figure 27) that can help keep the cutting area clear by blowing and redirecting the wood dust towards the dust collec- tor.

Figure 27. Chip Blower.

|

|

|

|

|

|

|

|

|

|

|

|

G8030 3 H.P. Overarm Router | |||