The miter fence can be adjusted by loosening the two bolts that hold it to the miter gauge and then sliding it in the desired direction.

The support fence slides up and down the miter fence and can be locked to hold the back of the workpiece in place.

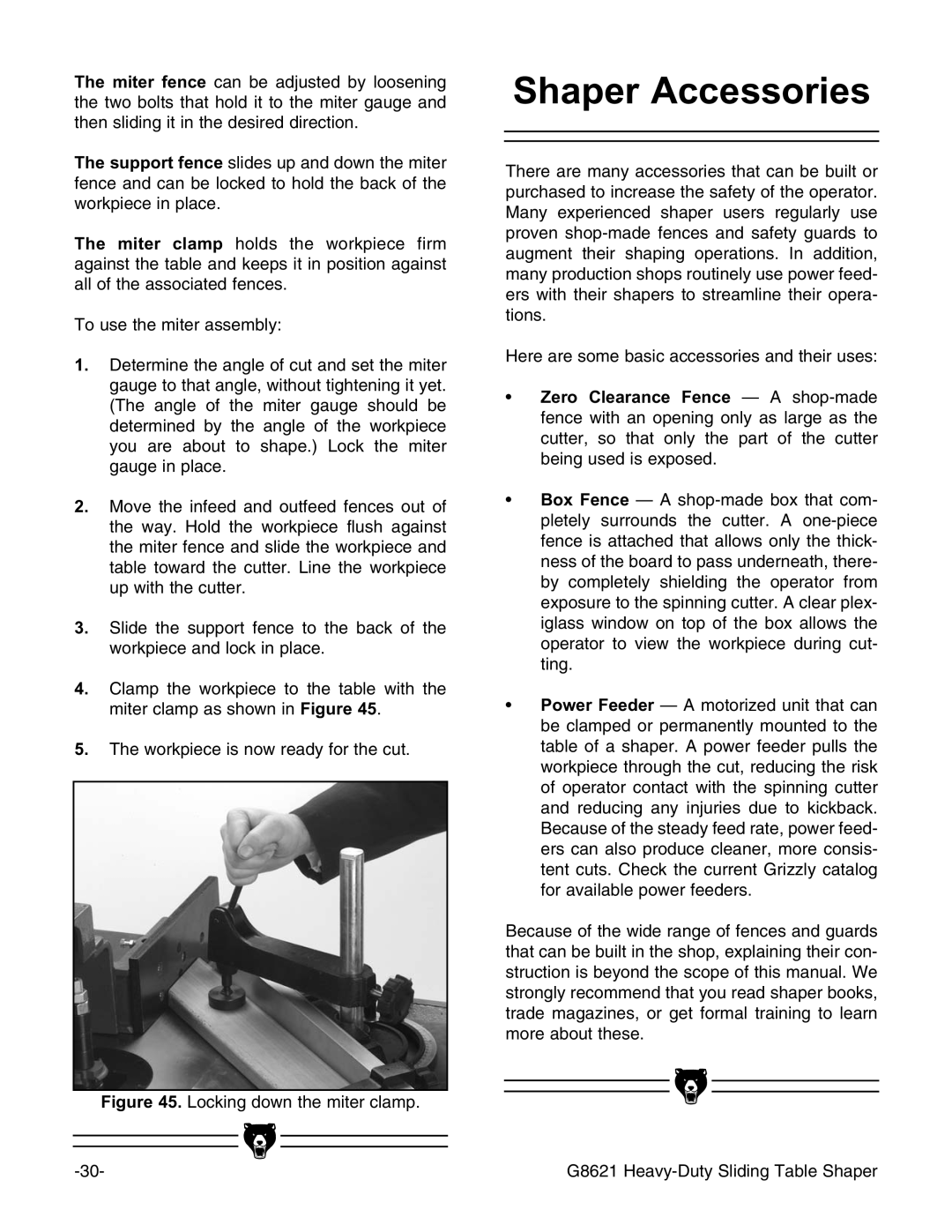

The miter clamp holds the workpiece firm against the table and keeps it in position against all of the associated fences.

To use the miter assembly:

1.Determine the angle of cut and set the miter gauge to that angle, without tightening it yet. (The angle of the miter gauge should be determined by the angle of the workpiece you are about to shape.) Lock the miter gauge in place.

2.Move the infeed and outfeed fences out of the way. Hold the workpiece flush against the miter fence and slide the workpiece and table toward the cutter. Line the workpiece up with the cutter.

3.Slide the support fence to the back of the workpiece and lock in place.

4.Clamp the workpiece to the table with the miter clamp as shown in Figure 45.

5.The workpiece is now ready for the cut.

Figure 45. Locking down the miter clamp.

Shaper Accessories

There are many accessories that can be built or purchased to increase the safety of the operator. Many experienced shaper users regularly use proven

Here are some basic accessories and their uses:

•Zero Clearance Fence — A

•Box Fence — A

•Power Feeder — A motorized unit that can be clamped or permanently mounted to the table of a shaper. A power feeder pulls the workpiece through the cut, reducing the risk of operator contact with the spinning cutter and reducing any injuries due to kickback. Because of the steady feed rate, power feed- ers can also produce cleaner, more consis- tent cuts. Check the current Grizzly catalog for available power feeders.

Because of the wide range of fences and guards that can be built in the shop, explaining their con- struction is beyond the scope of this manual. We strongly recommend that you read shaper books, trade magazines, or get formal training to learn more about these.

|

|

|

|

|

|

|

|

|

| G8621 | |

|

|