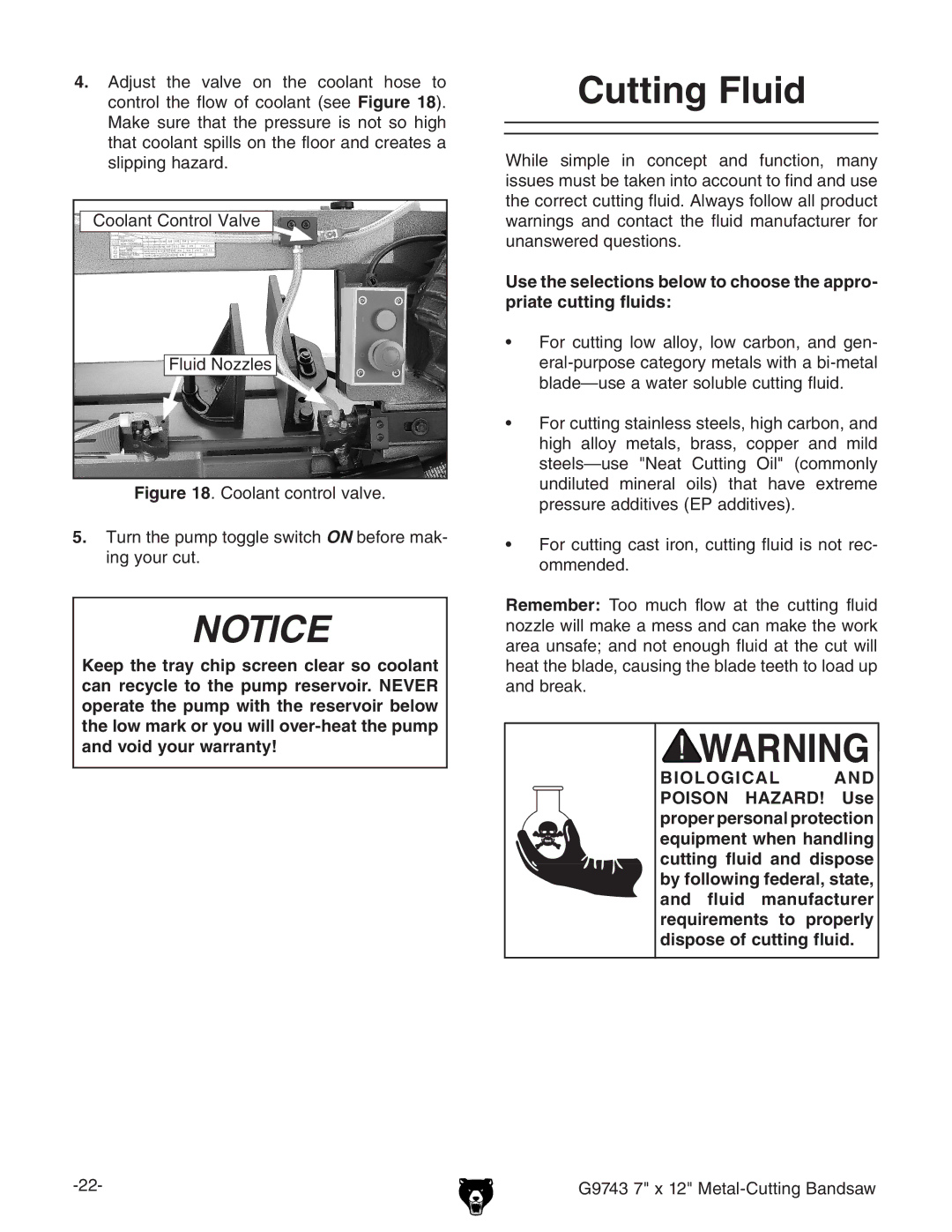

4.Adjust the valve on the coolant hose to control the flow of coolant (see Figure 18). Make sure that the pressure is not so high that coolant spills on the floor and creates a slipping hazard.

Coolant Control Valve

Fluid Nozzles

Figure 18. Coolant control valve.

5.Turn the pump toggle switch ON before mak-

ing your cut.

NOTICE

Keep the tray chip screen clear so coolant can recycle to the pump reservoir. NEVER operate the pump with the reservoir below the low mark or you will

Cutting Fluid

While simple in concept and function, many issues must be taken into account to find and use the correct cutting fluid. Always follow all product warnings and contact the fluid manufacturer for unanswered questions.

Use the selections below to choose the appro- priate cutting fluids:

•For cutting low alloy, low carbon, and gen-

•For cutting stainless steels, high carbon, and high alloy metals, brass, copper and mild

•For cutting cast iron, cutting fluid is not rec- ommended.

Remember: Too much flow at the cutting fluid nozzle will make a mess and can make the work area unsafe; and not enough fluid at the cut will heat the blade, causing the blade teeth to load up and break.

BIOLOGICAL | AND |

POISON HAZARD! | Use |

proper personal protection | |

equipment when handling | |

cutting fluid and dispose | |

by following federal, state, | |

and fluid manufacturer | |

requirements to properly | |

dispose of cutting fluid. | |

G9743 7" x 12" |