Blade Guide

Bearings

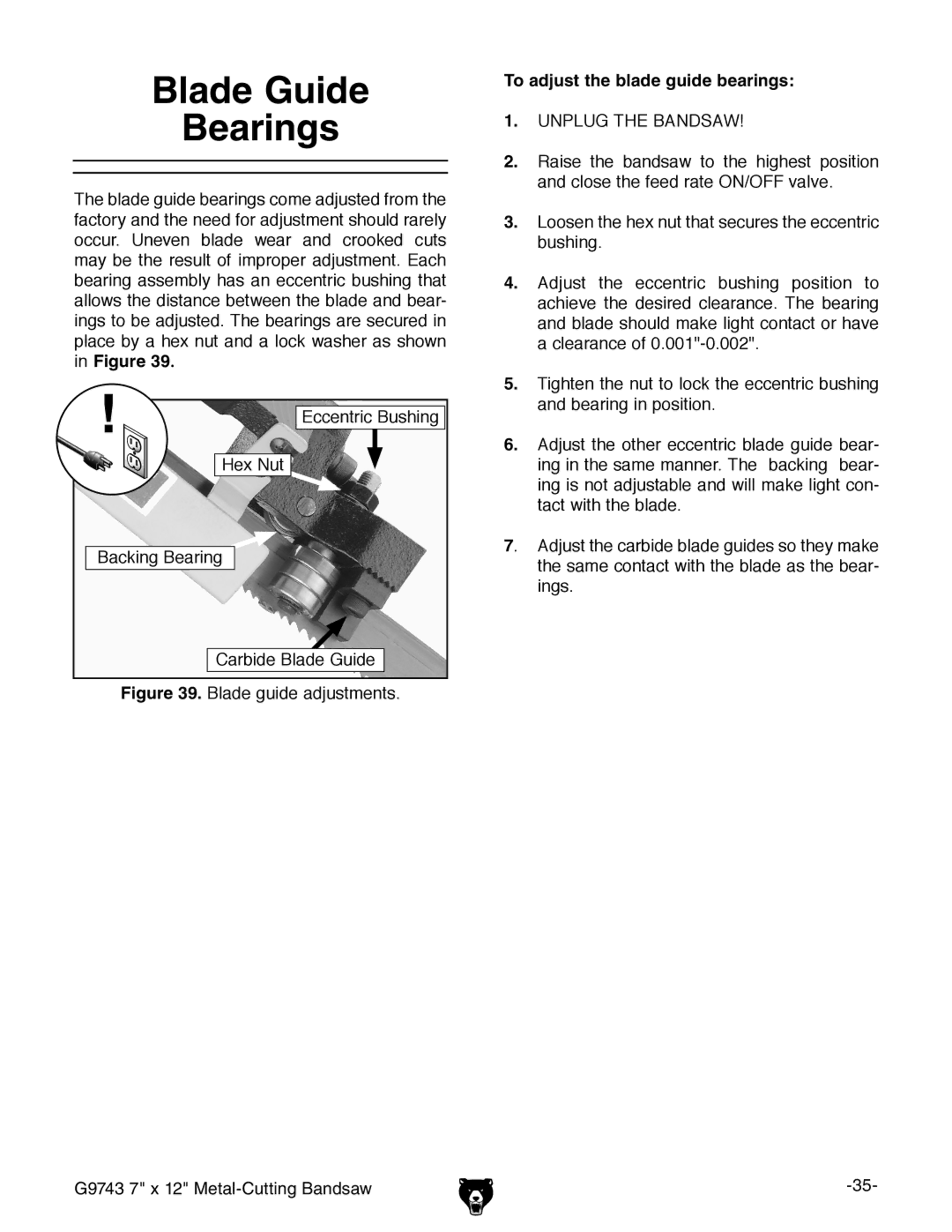

The blade guide bearings come adjusted from the factory and the need for adjustment should rarely occur. Uneven blade wear and crooked cuts may be the result of improper adjustment. Each bearing assembly has an eccentric bushing that allows the distance between the blade and bear- ings to be adjusted. The bearings are secured in place by a hex nut and a lock washer as shown in Figure 39.

Eccentric Bushing |

Hex Nut |

Backing Bearing |

Carbide Blade Guide |

Figure 39. Blade guide adjustments.

To adjust the blade guide bearings:

1.UNPLUG THE BANDSAW!

2.Raise the bandsaw to the highest position and close the feed rate ON/OFF valve.

3.Loosen the hex nut that secures the eccentric bushing.

4.Adjust the eccentric bushing position to achieve the desired clearance. The bearing and blade should make light contact or have a clearance of

5.Tighten the nut to lock the eccentric bushing and bearing in position.

6.Adjust the other eccentric blade guide bear- ing in the same manner. The backing bear- ing is not adjustable and will make light con- tact with the blade.

7. Adjust the carbide blade guides so they make the same contact with the blade as the bear- ings.

G9743 7" x 12" |