Depth Stop

The Model G9969 has a depth stop that allows you to drill repeated

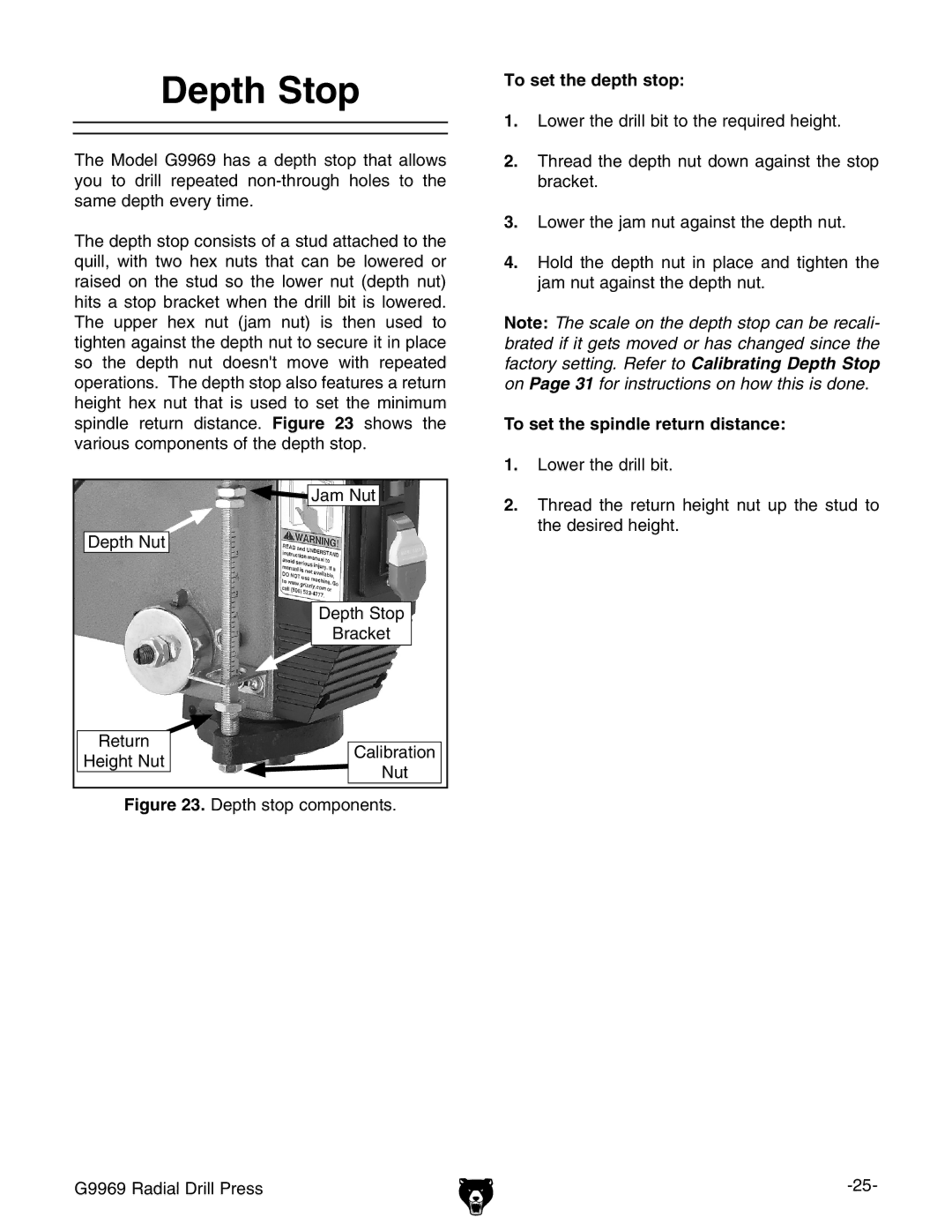

The depth stop consists of a stud attached to the quill, with two hex nuts that can be lowered or raised on the stud so the lower nut (depth nut) hits a stop bracket when the drill bit is lowered. The upper hex nut (jam nut) is then used to tighten against the depth nut to secure it in place so the depth nut doesn't move with repeated operations. The depth stop also features a return height hex nut that is used to set the minimum spindle return distance. Figure 23 shows the various components of the depth stop.

To set the depth stop:

1.Lower the drill bit to the required height.

2.Thread the depth nut down against the stop bracket.

3.Lower the jam nut against the depth nut.

4.Hold the depth nut in place and tighten the jam nut against the depth nut.

Note: The scale on the depth stop can be recali- brated if it gets moved or has changed since the factory setting. Refer to Calibrating Depth Stop on Page 31 for instructions on how this is done.

To set the spindle return distance:

|

| 1. | Lower the drill bit. |

| Jam Nut | 2. | Thread the return height nut up the stud to |

|

| ||

Depth Nut |

|

| the desired height. |

|

|

| |

| Depth Stop |

|

|

| Bracket |

|

|

Return | Calibration |

|

|

Height Nut |

|

| |

Nut |

|

| |

|

|

|

Figure 23. Depth stop components.

G9969 Radial Drill Press |