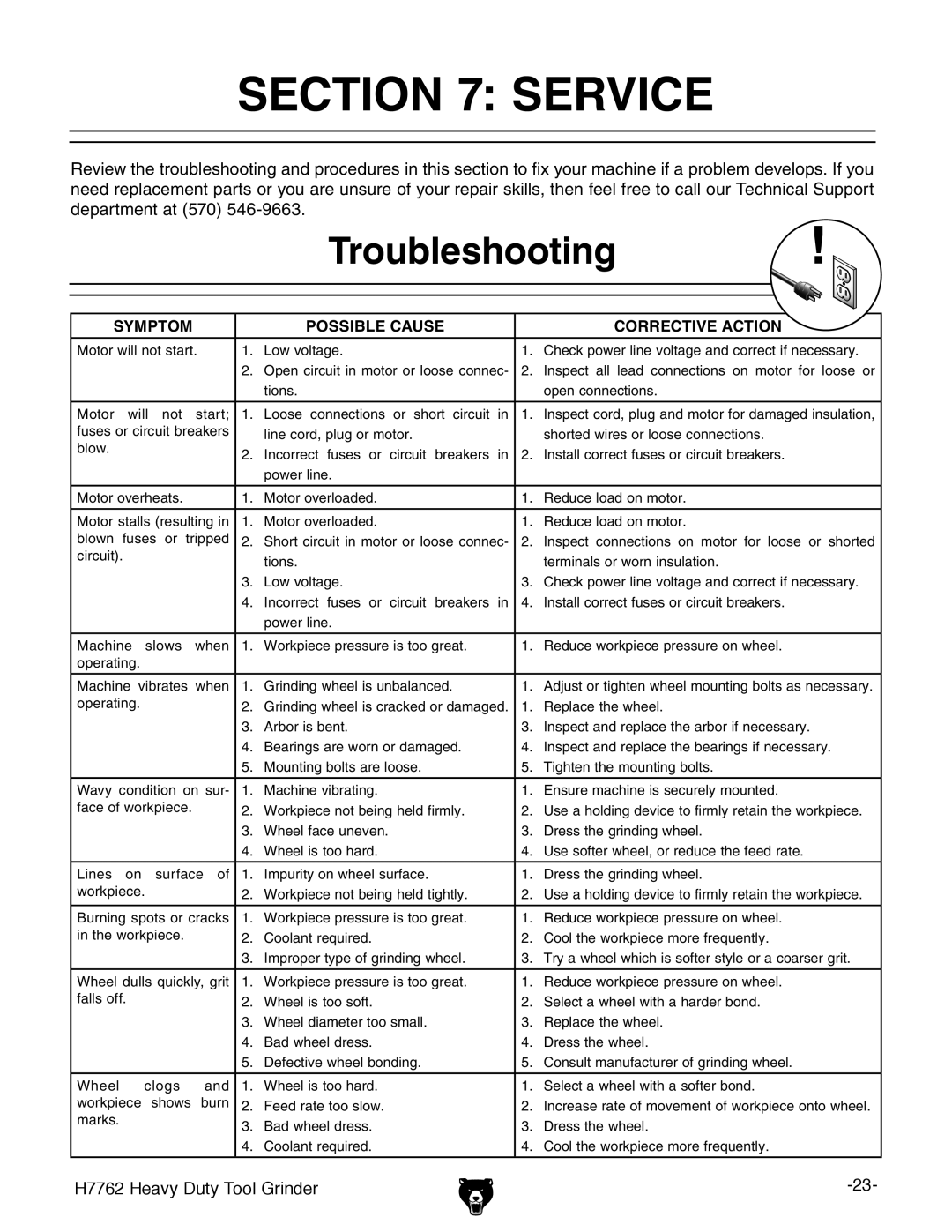

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support department at (570)

Troubleshooting

SYMPTOM |

|

| POSSIBLE CAUSE |

| CORRECTIVE ACTION | |

|

|

|

|

| ||

Motor will not start. | 1. | Low voltage. | 1. | Check power line voltage and correct if necessary. | ||

|

|

| 2. | Open circuit in motor or loose connec- | 2. | Inspect all lead connections on motor for loose or |

|

|

|

| tions. |

| open connections. |

|

|

|

|

| ||

Motor will not start; | 1. | Loose connections or short circuit in | 1. | Inspect cord, plug and motor for damaged insulation, | ||

fuses or circuit breakers |

| line cord, plug or motor. |

| shorted wires or loose connections. | ||

blow. |

|

| 2. | Incorrect fuses or circuit breakers in | 2. | Install correct fuses or circuit breakers. |

|

|

| ||||

|

|

|

| power line. |

|

|

|

|

|

|

|

| |

Motor overheats. |

| 1. | Motor overloaded. | 1. | Reduce load on motor. | |

|

|

|

|

| ||

Motor stalls (resulting in | 1. | Motor overloaded. | 1. | Reduce load on motor. | ||

blown fuses or tripped | 2. | Short circuit in motor or loose connec- | 2. | Inspect connections on motor for loose or shorted | ||

circuit). |

|

|

| tions. |

| terminals or worn insulation. |

|

|

|

|

| ||

|

|

| 3. | Low voltage. | 3. | Check power line voltage and correct if necessary. |

|

|

| 4. | Incorrect fuses or circuit breakers in | 4. | Install correct fuses or circuit breakers. |

|

|

|

| power line. |

|

|

|

|

|

|

|

|

|

Machine | slows | when | 1. | Workpiece pressure is too great. | 1. | Reduce workpiece pressure on wheel. |

operating. |

|

|

|

|

|

|

|

|

|

|

|

| |

Machine vibrates | when | 1. | Grinding wheel is unbalanced. | 1. | Adjust or tighten wheel mounting bolts as necessary. | |

operating. |

|

| 2. | Grinding wheel is cracked or damaged. | 1. | Replace the wheel. |

|

|

| 3. | Arbor is bent. | 3. | Inspect and replace the arbor if necessary. |

|

|

| 4. | Bearings are worn or damaged. | 4. | Inspect and replace the bearings if necessary. |

|

|

| 5. | Mounting bolts are loose. | 5. | Tighten the mounting bolts. |

|

|

|

|

| ||

Wavy condition on sur- | 1. | Machine vibrating. | 1. | Ensure machine is securely mounted. | ||

face of workpiece. |

| 2. | Workpiece not being held firmly. | 2. | Use a holding device to firmly retain the workpiece. | |

|

|

| 3. | Wheel face uneven. | 3. | Dress the grinding wheel. |

|

|

| 4. | Wheel is too hard. | 4. | Use softer wheel, or reduce the feed rate. |

|

|

|

|

| ||

Lines on surface of | 1. | Impurity on wheel surface. | 1. | Dress the grinding wheel. | ||

workpiece. |

| 2. | Workpiece not being held tightly. | 2. | Use a holding device to firmly retain the workpiece. | |

|

|

|

|

| ||

Burning spots or cracks | 1. | Workpiece pressure is too great. | 1. | Reduce workpiece pressure on wheel. | ||

in the workpiece. |

| 2. | Coolant required. | 2. | Cool the workpiece more frequently. | |

|

|

| 3. | Improper type of grinding wheel. | 3. | Try a wheel which is softer style or a coarser grit. |

|

|

|

|

| ||

Wheel dulls quickly, grit | 1. | Workpiece pressure is too great. | 1. | Reduce workpiece pressure on wheel. | ||

falls off. |

|

| 2. | Wheel is too soft. | 2. | Select a wheel with a harder bond. |

|

|

| 3. | Wheel diameter too small. | 3. | Replace the wheel. |

|

|

| 4. | Bad wheel dress. | 4. | Dress the wheel. |

|

|

| 5. | Defective wheel bonding. | 5. | Consult manufacturer of grinding wheel. |

|

|

|

|

|

|

|

Wheel | clogs | and | 1. | Wheel is too hard. | 1. | Select a wheel with a softer bond. |

workpiece | shows | burn | 2. | Feed rate too slow. | 2. | Increase rate of movement of workpiece onto wheel. |

marks. |

|

| 3. | Bad wheel dress. | 3. | Dress the wheel. |

|

|

| ||||

|

|

| 4. | Coolant required. | 4. | Cool the workpiece more frequently. |

|

|

|

| |||

H7762 Heavy Duty Tool Grinder |

| |||||