2.Align the angle gauge so that the pointer at the bottom of the gauge is pointing at 0º.

3.Tighten the lock handle further so that the angle gauge does not move.

4.Repeat Steps

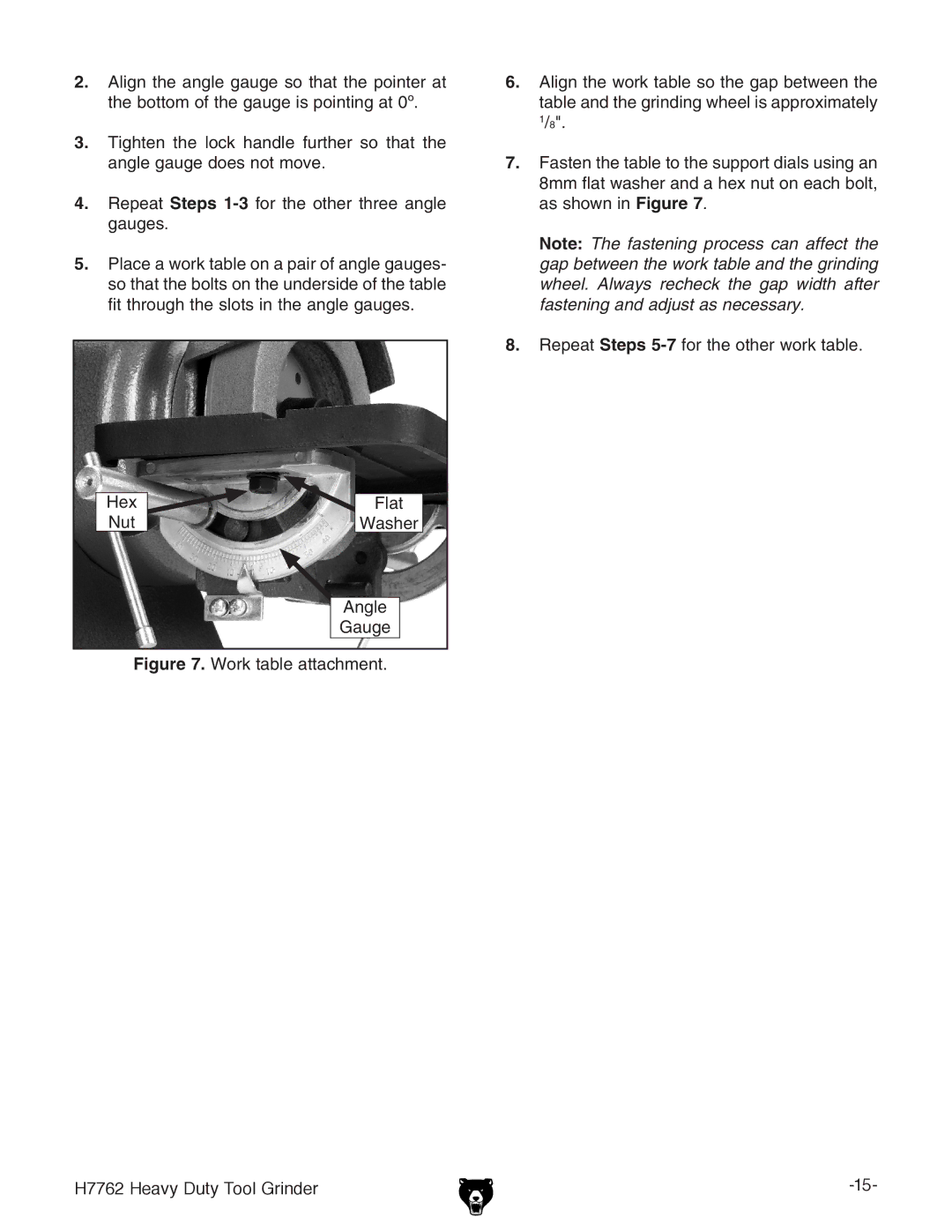

5.Place a work table on a pair of angle gauges- so that the bolts on the underside of the table fit through the slots in the angle gauges.

Hex | Flat |

Nut | Washer |

| Angle |

| Gauge |

Figure 7. Work table attachment.

6.Align the work table so the gap between the table and the grinding wheel is approximately 1/8".

7.Fasten the table to the support dials using an 8mm flat washer and a hex nut on each bolt, as shown in Figure 7.

Note: The fastening process can affect the gap between the work table and the grinding wheel. Always recheck the gap width after fastening and adjust as necessary.

8.Repeat Steps 5-7 for the other work table.

H7762 Heavy Duty Tool Grinder |