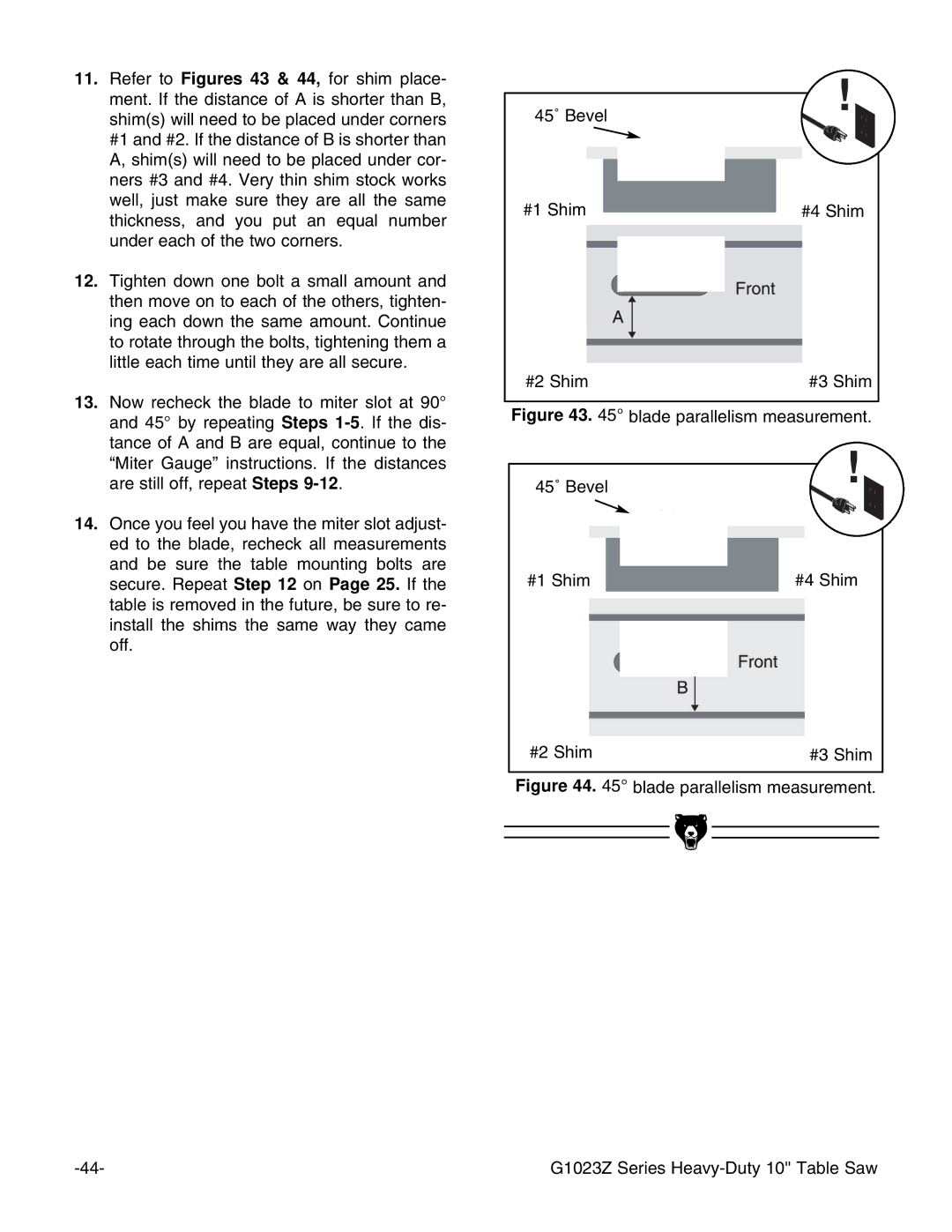

11.Refer to Figures 43 & 44, for shim place- ment. If the distance of A is shorter than B, shim(s) will need to be placed under corners #1 and #2. If the distance of B is shorter than A, shim(s) will need to be placed under cor- ners #3 and #4. Very thin shim stock works well, just make sure they are all the same thickness, and you put an equal number under each of the two corners.

12.Tighten down one bolt a small amount and then move on to each of the others, tighten- ing each down the same amount. Continue to rotate through the bolts, tightening them a little each time until they are all secure.

13.Now recheck the blade to miter slot at 90¡ and 45¡ by repeating Steps

14.Once you feel you have the miter slot adjust- ed to the blade, recheck all measurements and be sure the table mounting bolts are secure. Repeat Step 12 on Page 25. If the table is removed in the future, be sure to re- install the shims the same way they came off.

45û Bevel | ! |

| |

#1 Shim | #4 Shim |

#2 Shim | #3 Shim |

Figure 43. 45¡ blade parallelism measurement.

45û Bevel | ! |

#1 Shim | #4 Shim |

#2 Shim | #3 Shim |

Figure 44. 45¡ blade parallelism measurement.

|

|

|

|

|

|

|

|

|

|

|

|

G1023Z Series | |||