SECTION 6: MAINTENANCE

!

Always DISCONNECT POWER before servicing, adjusting, or doing maintenance to reduce the risk of accidental injury or electrocution.

Cleaning

Clean and lightly oil drill bits after each use to prevent rust and corrosion.

Clean dust off the hammer drill body with a dry rag or

Lubrication

The hammer drill was lubricated with grease before it left the

To add grease:

1.DISCONNECT TOOL FROM POWER!

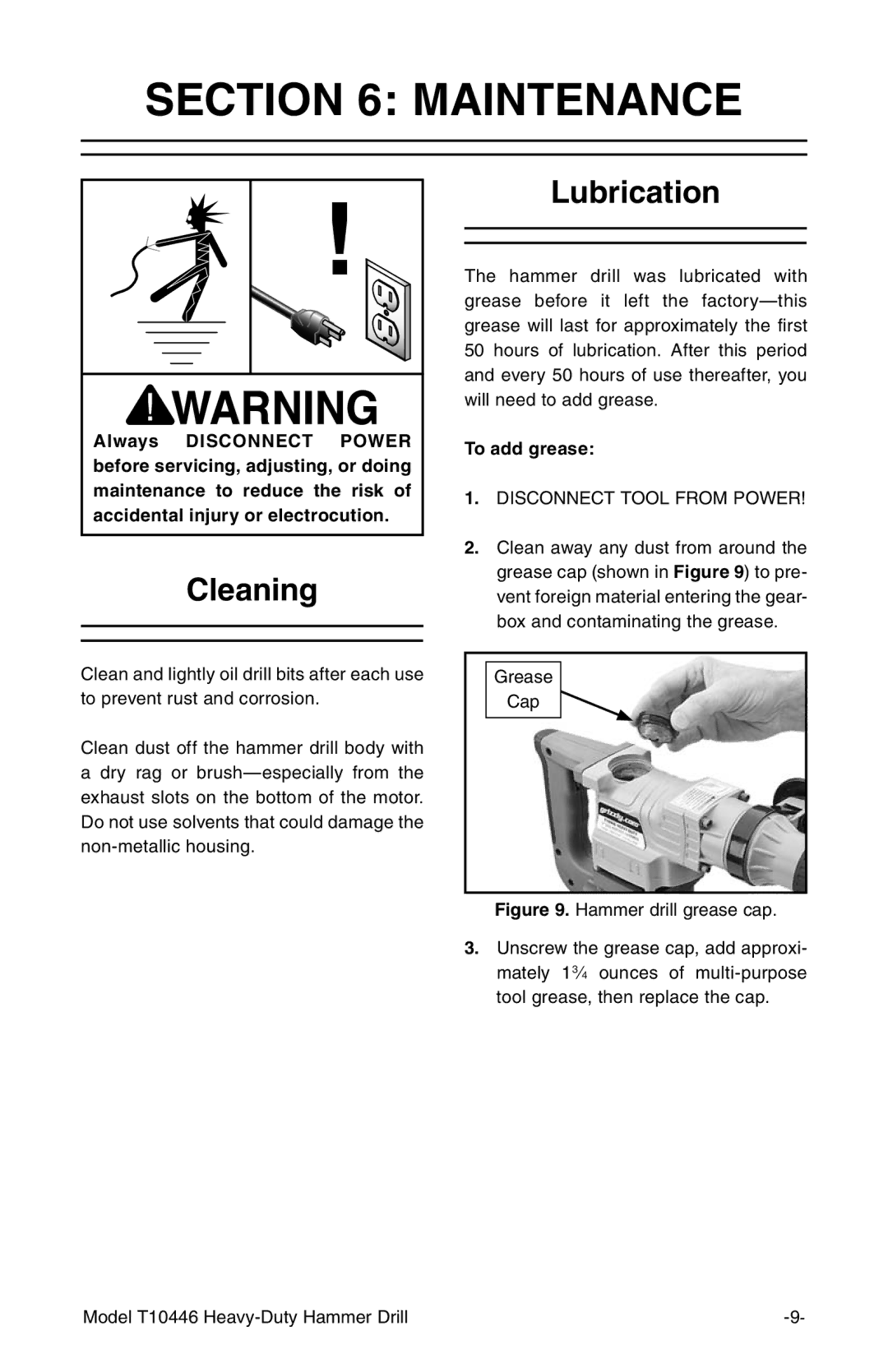

2.Clean away any dust from around the grease cap (shown in Figure 9) to pre- vent foreign material entering the gear- box and contaminating the grease.

Grease

Cap

Figure 9. Hammer drill grease cap.

3.Unscrew the grease cap, add approxi- mately 1⁜3⁄4 ounces of multi-purpose tool grease, then replace the cap.

Model T10446 |