Depth Stop |

| Operation |

|

|

|

|

|

|

Use the depth stop to halt the advance of the bit at the desired drilling depth.

To attach the depth stop:

1.DISCONNECT TOOL FROM POWER!

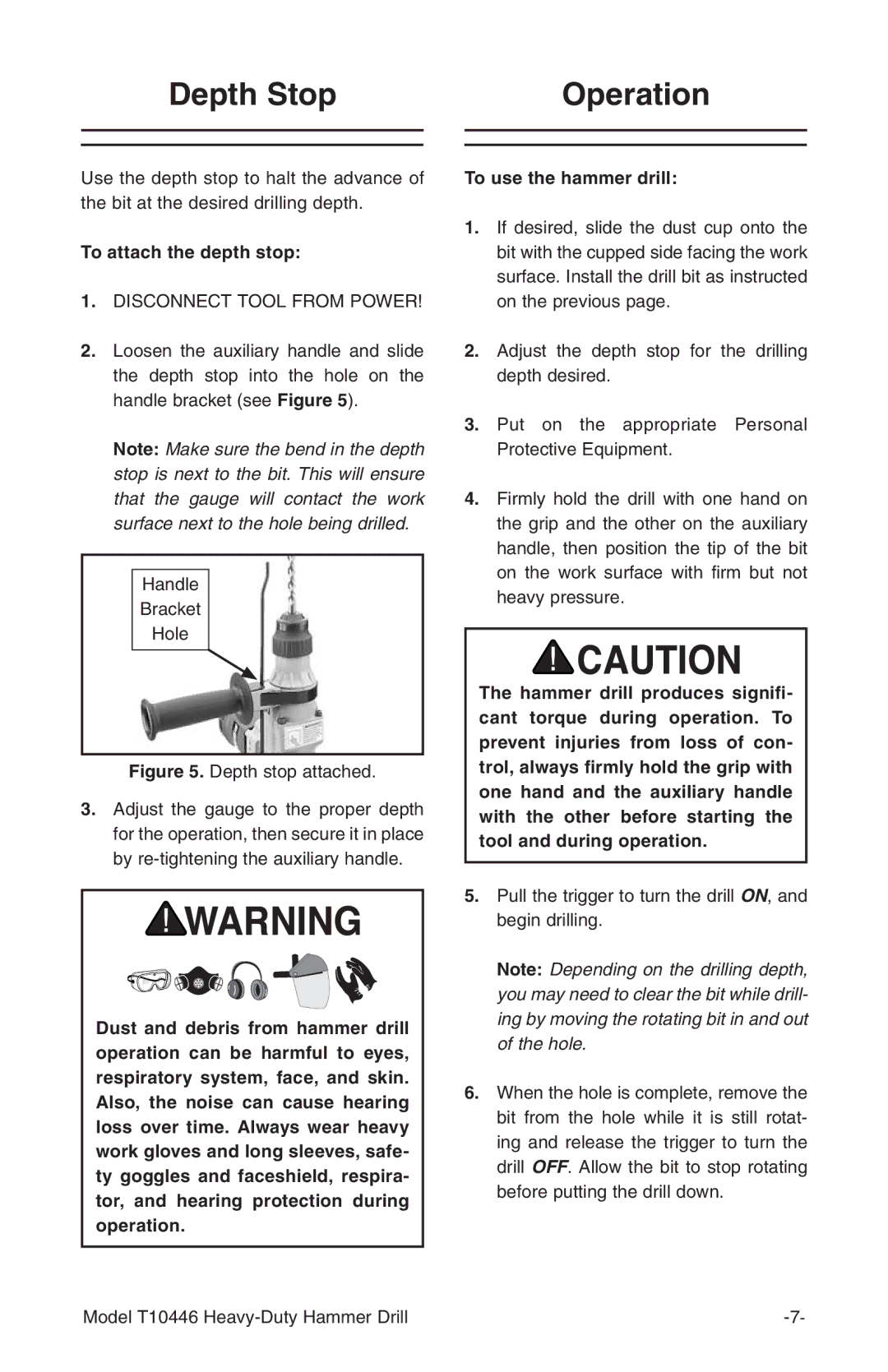

2.Loosen the auxiliary handle and slide the depth stop into the hole on the handle bracket (see Figure 5).

Note: Make sure the bend in the depth stop is next to the bit. This will ensure that the gauge will contact the work surface next to the hole being drilled.

Handle

Bracket

Hole

Figure 5. Depth stop attached.

3.Adjust the gauge to the proper depth for the operation, then secure it in place by

Dust and debris from hammer drill operation can be harmful to eyes, respiratory system, face, and skin. Also, the noise can cause hearing loss over time. Always wear heavy work gloves and long sleeves, safe- ty goggles and faceshield, respira- tor, and hearing protection during operation.

To use the hammer drill:

1.If desired, slide the dust cup onto the bit with the cupped side facing the work surface. Install the drill bit as instructed on the previous page.

2.Adjust the depth stop for the drilling depth desired.

3.Put on the appropriate Personal Protective Equipment.

4.Firmly hold the drill with one hand on the grip and the other on the auxiliary handle, then position the tip of the bit on the work surface with firm but not heavy pressure.

The hammer drill produces signifi- cant torque during operation. To prevent injuries from loss of con- trol, always firmly hold the grip with one hand and the auxiliary handle with the other before starting the tool and during operation.

5.Pull the trigger to turn the drill ON, and begin drilling.

Note: Depending on the drilling depth, you may need to clear the bit while drill- ing by moving the rotating bit in and out of the hole.

6.When the hole is complete, remove the bit from the hole while it is still rotat- ing and release the trigger to turn the drill OFF. Allow the bit to stop rotating before putting the drill down.

Model T10446 |