SECTION 7: SERVICE

Troubleshooting

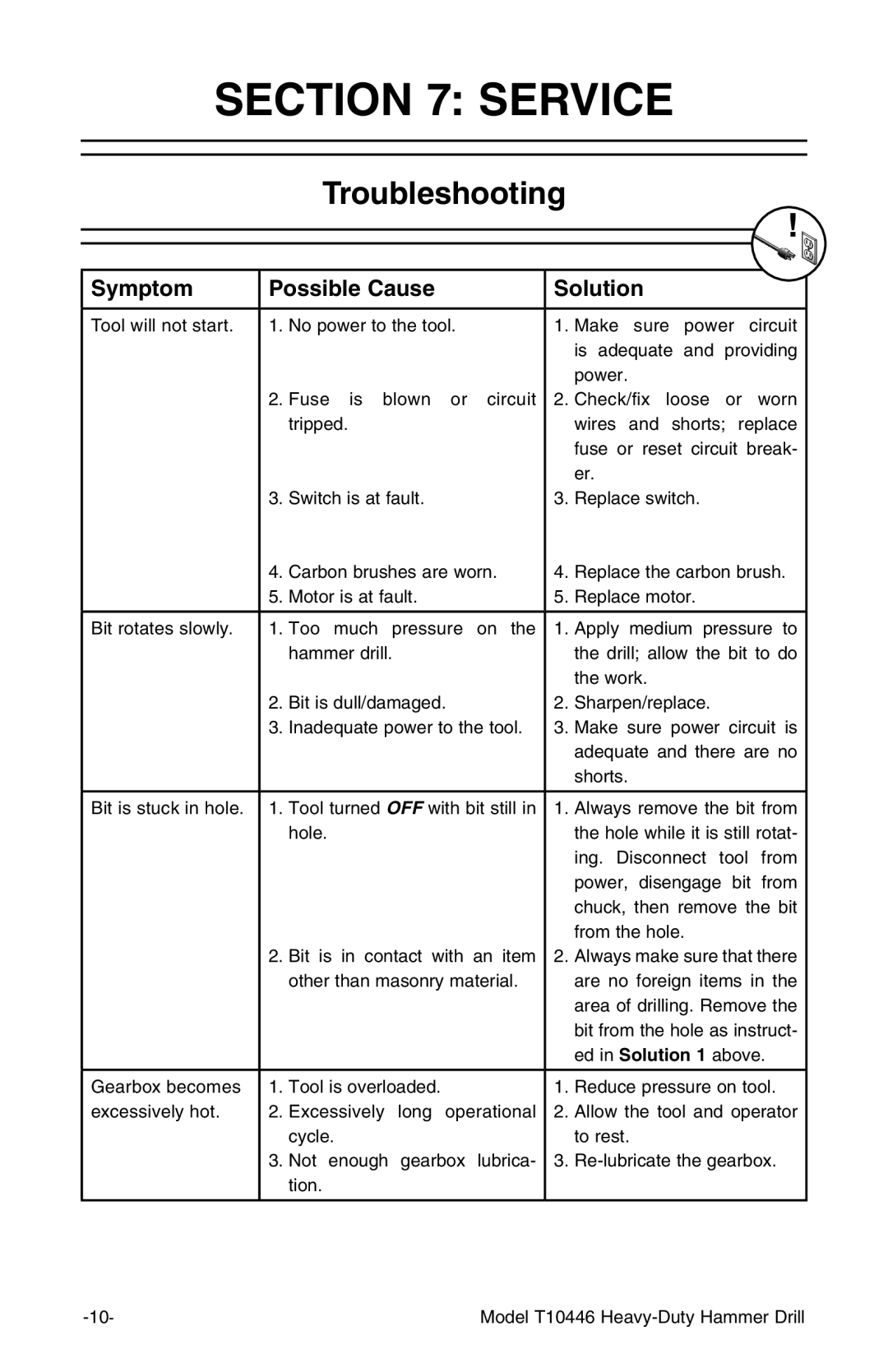

Symptom | Possible Cause | Solution |

|

|

|

| ||

|

|

|

|

| ||||

Tool will not start. | 1. No power to the tool. | 1. | Make sure | power circuit | ||||

|

|

|

| is adequate | and | providing | ||

|

|

|

| power. |

|

|

|

|

| 2. | Fuse is blown or circuit | 2. | Check/fix | loose | or | worn | |

|

| tripped. |

| wires and | shorts; replace | |||

|

|

|

| fuse or reset circuit break- | ||||

|

|

|

| er. |

|

|

|

|

| 3. | Switch is at fault. | 3. | Replace switch. |

|

| ||

| 4. | Carbon brushes are worn. | 4. | Replace the carbon brush. | ||||

| 5. | Motor is at fault. | 5. | Replace motor. |

|

| ||

|

|

|

| |||||

Bit rotates slowly. | 1. Too much pressure on the | 1. | Apply medium pressure to | |||||

|

| hammer drill. |

| the drill; allow the bit to do | ||||

|

|

|

| the work. |

|

|

|

|

| 2. | Bit is dull/damaged. | 2. | Sharpen/replace. |

|

| ||

| 3. | Inadequate power to the tool. | 3. | Make sure power circuit is | ||||

|

|

|

| adequate and there are no | ||||

|

|

|

| shorts. |

|

|

|

|

|

|

|

| |||||

Bit is stuck in hole. | 1. Tool turned OFF with bit still in | 1. | Always remove the bit from | |||||

|

| hole. |

| the hole while it is still rotat- | ||||

|

|

|

| ing. Disconnect | tool | from | ||

|

|

|

| power, disengage bit | from | |||

|

|

|

| chuck, then remove the bit | ||||

|

|

|

| from the hole. |

|

| ||

| 2. | Bit is in contact with an item | 2. | Always make sure that there | ||||

|

| other than masonry material. |

| are no foreign items in the | ||||

|

|

|

| area of drilling. Remove the | ||||

|

|

|

| bit from the hole as instruct- | ||||

|

|

|

| ed in Solution 1 above. | ||||

|

|

|

| |||||

Gearbox becomes | 1. Tool is overloaded. | 1. | Reduce pressure on tool. | |||||

excessively hot. | 2. Excessively long operational | 2. | Allow the tool and operator | |||||

|

| cycle. |

| to rest. |

|

|

|

|

| 3. | Not enough gearbox lubrica- | 3. | |||||

|

| tion. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model T10446 |