Adjusting Blade Bow

Tools Required | Qty. |

....................................1 |

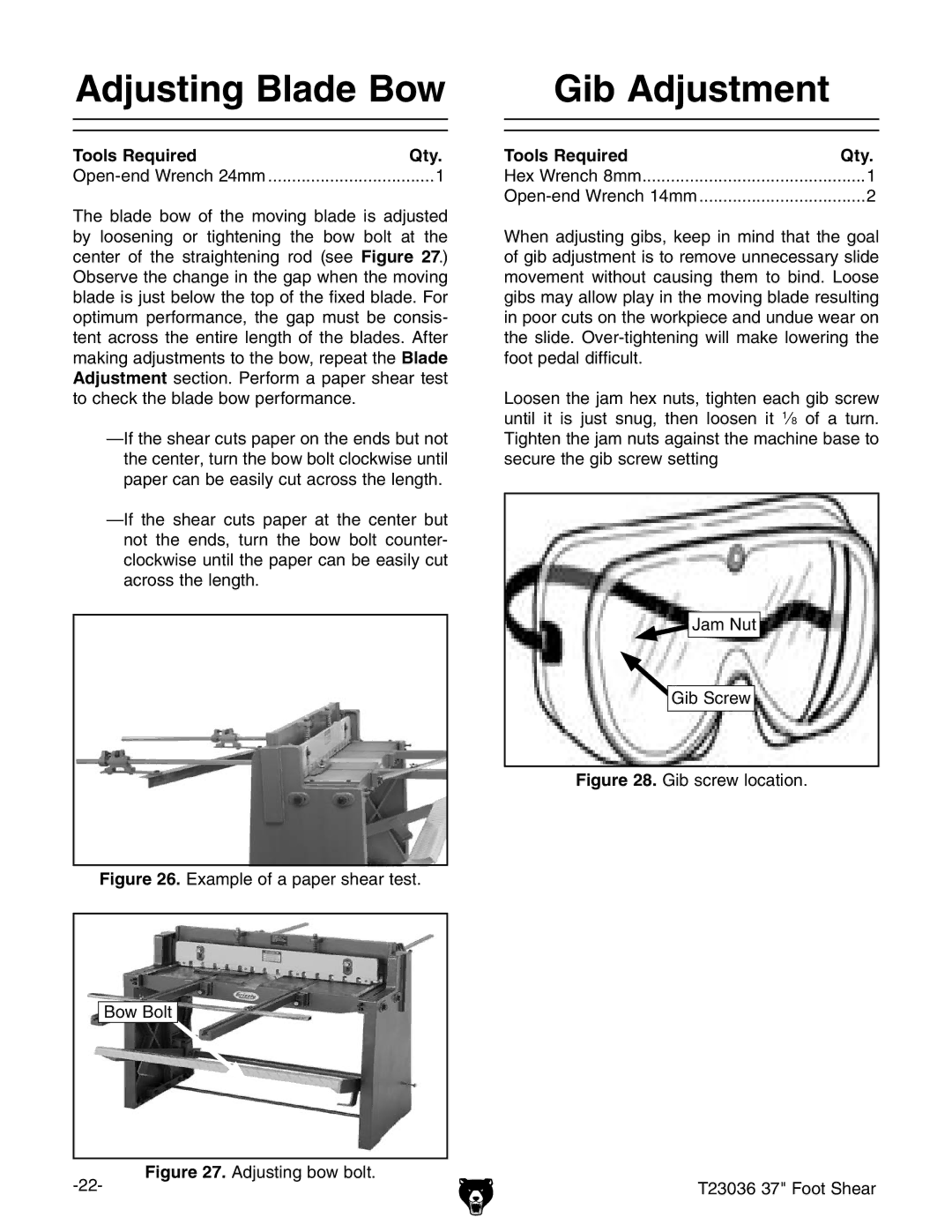

The blade bow of the moving blade is adjusted by loosening or tightening the bow bolt at the center of the straightening rod (see Figure 27.) Observe the change in the gap when the moving blade is just below the top of the fixed blade. For optimum performance, the gap must be consis- tent across the entire length of the blades. After making adjustments to the bow, repeat the Blade Adjustment section. Perform a paper shear test to check the blade bow performance.

Figure 26. Example of a paper shear test.

Bow Bolt

Gib Adjustment |

|

Tools Required | Qty. |

Hex Wrench 8mm | 1 |

2 |

When adjusting gibs, keep in mind that the goal of gib adjustment is to remove unnecessary slide movement without causing them to bind. Loose gibs may allow play in the moving blade resulting in poor cuts on the workpiece and undue wear on the slide.

Loosen the jam hex nuts, tighten each gib screw until it is just snug, then loosen it 1⁄8 of a turn. Tighten the jam nuts against the machine base to secure the gib screw setting

Jam Nut

![]() Gib Screw

Gib Screw

Figure 28. Gib screw location.

Figure 27. Adjusting bow bolt. | |

T23036 37" Foot Shear |