4.Looking behind the

Adjusting Blade Bow section.

5.Using a sheet of paper, confirm that you have proper contact by making several cuts along the length of the blade. The shear should cut through the paper cleanly.

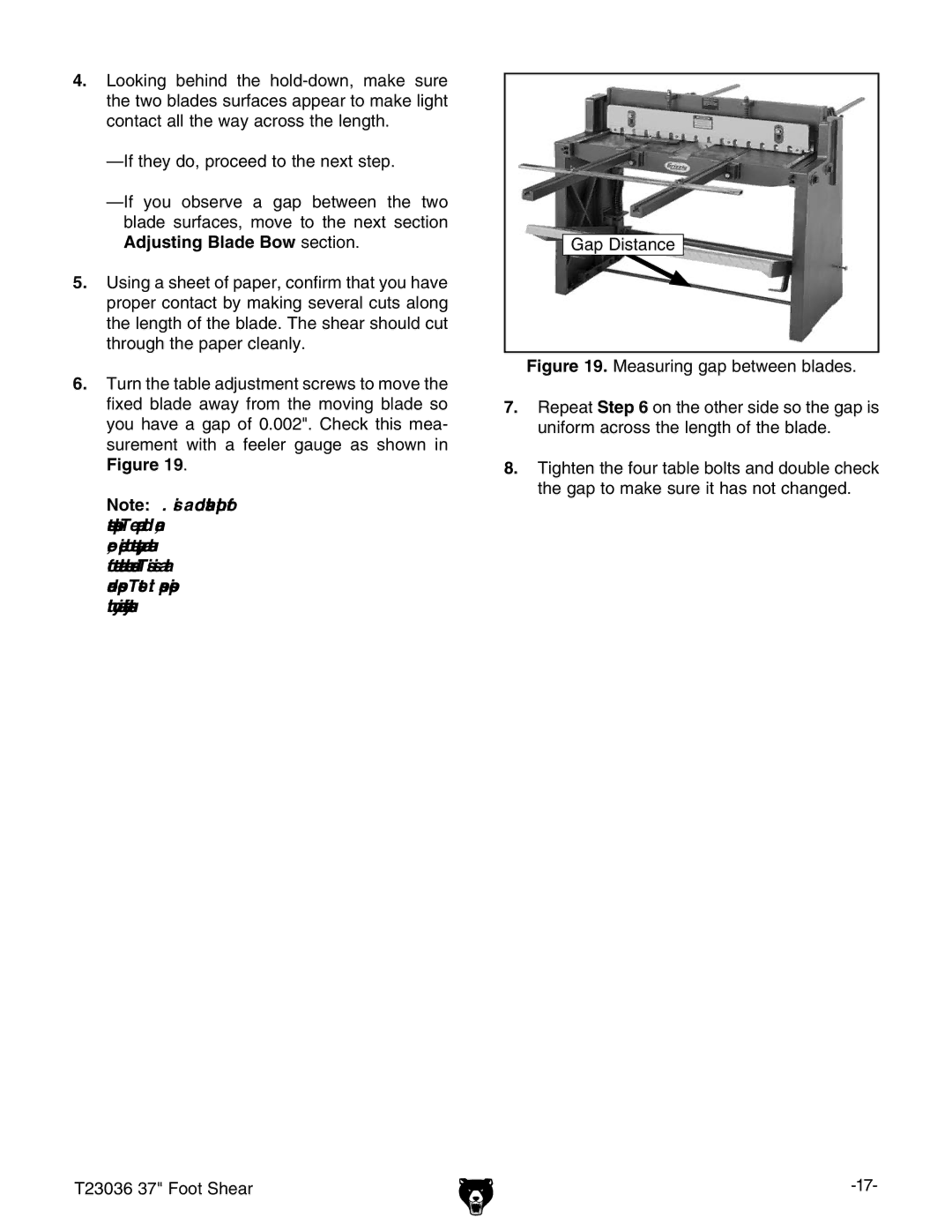

6.Turn the table adjustment screws to move the fixed blade away from the moving blade so you have a gap of 0.002". Check this mea- surement with a feeler gauge as shown in

Figure 19.

Note: 0.002" is a good starting point for most operations. The gap width will change, however, depending on the type and gauge of the material being sheared. This is a trial-

T23036 37" Foot Shear

Gap Distance