5.Rinse these parts thoroughly in solvent, then dry with compressed air or let air dry.

DO NOT soak the spray gun body in solvent. Prolonged exposure to sol- vent will rapidly deteriorate the spray gun washers and seals.

Note: If the small holes in the atom- izing cap become blocked, soak the cap in clean solvent. If the blockage still exists, clear the blockage with a small needle, taking great care to not enlarge or damage the hole. Damage to the hole will create a disrupted spray pattern.

6.Use an old tooth brush and solvent to clean the inner orifice and other hard to reach areas on the outside of the gun body.

7.Wipe the gun body dry with a lint free shop towel.

Lubrication

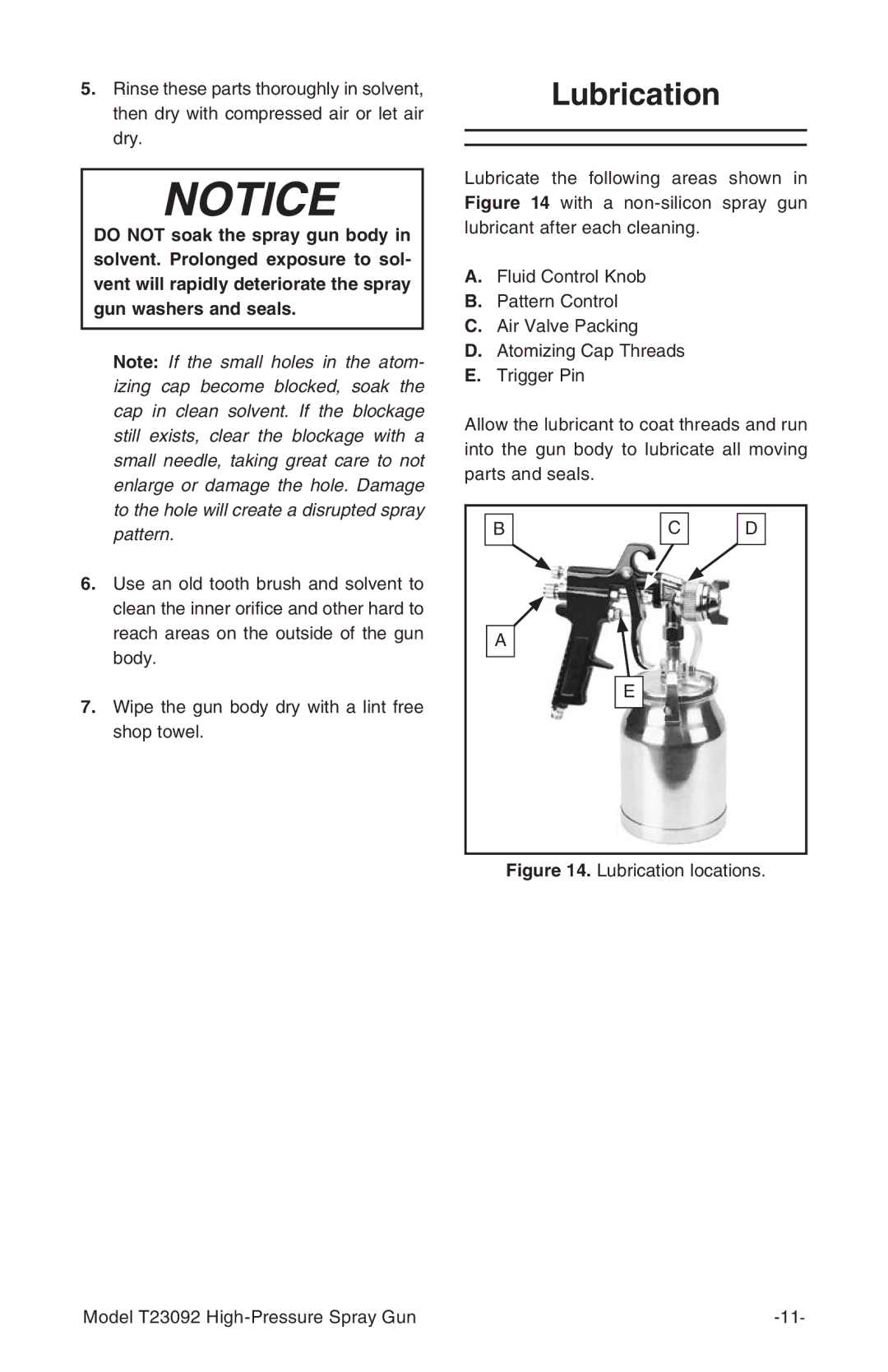

Lubricate the following areas shown in Figure 14 with a

A.Fluid Control Knob

B.Pattern Control

C.Air Valve Packing

D.Atomizing Cap Threads

E.Trigger Pin

Allow the lubricant to coat threads and run into the gun body to lubricate all moving parts and seals.

B |

| C |

| D |

|

|

|

|

|

A

E

Figure 14. Lubrication locations.

Model T23092 |