SECTION 7: SERVICE

Troubleshooting

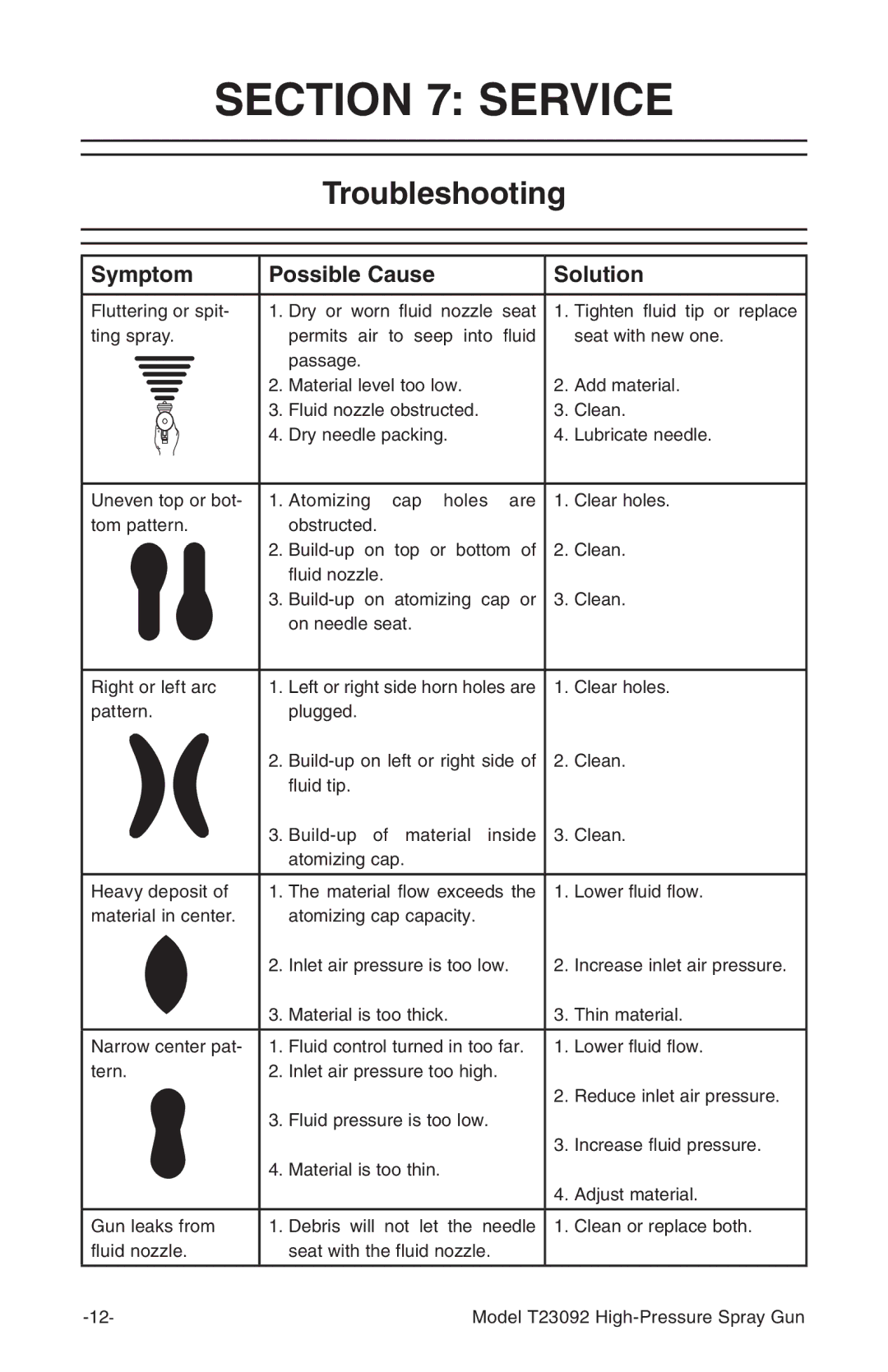

Symptom | Possible Cause |

|

| Solution | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Fluttering or spit- | 1. Dry or worn | fluid | nozzle | seat | 1. | Tighten fluid tip or replace | ||||||||

ting spray. |

| permits air to seep into fluid |

| seat with new one. | ||||||||||

|

|

|

|

|

|

|

|

| passage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| 2. | Material level too low. |

| 2. | Add material. | ||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| 3. | Fluid nozzle obstructed. |

| 3. | Clean. | ||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| 4. | Dry needle packing. |

| 4. | Lubricate needle. | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Uneven top or bot- | 1. Atomizing | cap | holes | are | 1. | Clear holes. | ||||||||

tom pattern. |

| obstructed. |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| 2. | 2. | Clean. | ||||

|

|

|

|

|

|

|

|

| fluid nozzle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| 3. | 3. | Clean. | ||||

|

|

|

|

|

|

|

|

| on needle seat. |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Right or left arc | 1. Left or right side horn holes are | 1. | Clear holes. | |||||||||||

pattern. |

| plugged. |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| 2. | 2. | Clean. | ||||

|

|

|

|

|

|

|

|

| fluid tip. |

|

|

|

|

|

|

|

|

|

|

|

|

| 3. | 3. | Clean. | ||||

|

|

|

|

|

|

|

|

| atomizing cap. |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||||

Heavy deposit of | 1. The material flow exceeds the | 1. | Lower fluid flow. | |||||||||||

material in center. |

| atomizing cap capacity. |

|

|

| |||||||||

|

|

|

|

|

|

|

| 2. | Inlet air pressure is too low. | 2. | Increase inlet air pressure. | |||

|

|

|

|

|

|

|

| 3. | Material is too thick. |

| 3. | Thin material. | ||

|

|

|

|

|

|

|

|

|

|

| ||||

Narrow center pat- | 1. Fluid control turned in too far. | 1. | Lower fluid flow. | |||||||||||

tern. | 2. Inlet air pressure too high. |

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| 2. | Reduce inlet air pressure. |

|

|

|

|

|

|

|

| 3. | Fluid pressure is too low. |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| 3. | Increase fluid pressure. |

|

|

|

|

|

|

|

| 4. | Material is too thin. |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| 4. | Adjust material. |

|

|

|

|

|

|

|

|

|

|

|

| |||

Gun leaks from | 1. Debris will not let | the needle | 1. | Clean or replace both. | ||||||||||

fluid nozzle. |

| seat with the fluid nozzle. |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model T23092 |