7. Service

Fan Propeller Removal and Installation

The fan propeller is secured to the motor shaft by the use of a

Although the

Threaded Bushing Holes

The threaded holes within the bushing are provided for disassembly purposes only. Do not attempt to use these holes for reassembly. They do not allow the parts to lock onto the shaft and thereby create a very hazardous operating condition.

Clearance Holes

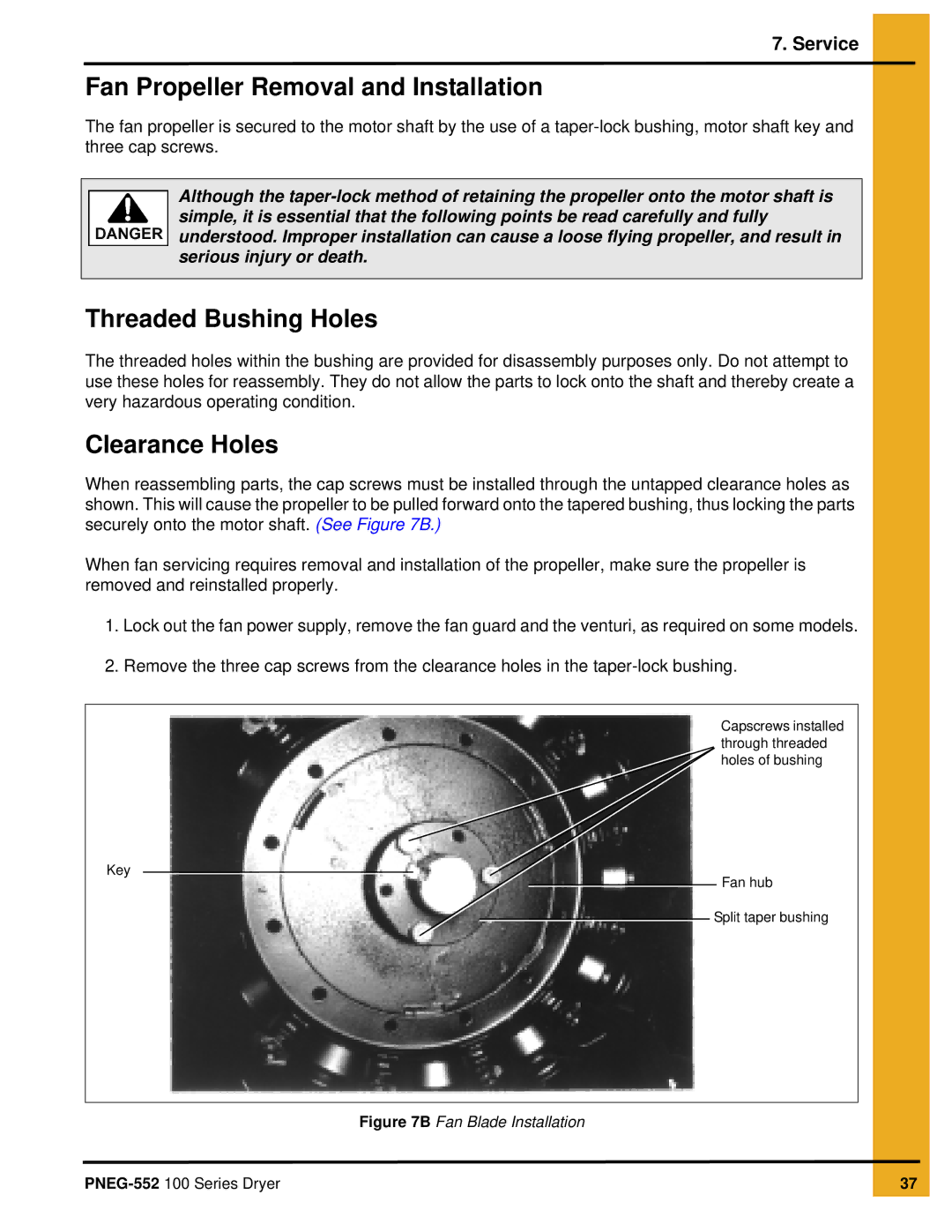

When reassembling parts, the cap screws must be installed through the untapped clearance holes as shown. This will cause the propeller to be pulled forward onto the tapered bushing, thus locking the parts securely onto the motor shaft. (See Figure 7B.)

When fan servicing requires removal and installation of the propeller, make sure the propeller is removed and reinstalled properly.

1.Lock out the fan power supply, remove the fan guard and the venturi, as required on some models.

2.Remove the three cap screws from the clearance holes in the

Capscrews installed through threaded holes of bushing

Key

Fan hub

Split taper bushing

Figure 7B Fan Blade Installation

| 37 |