Motor assembly

6.1 Motor assembly

6.1.5Installation examples

Note

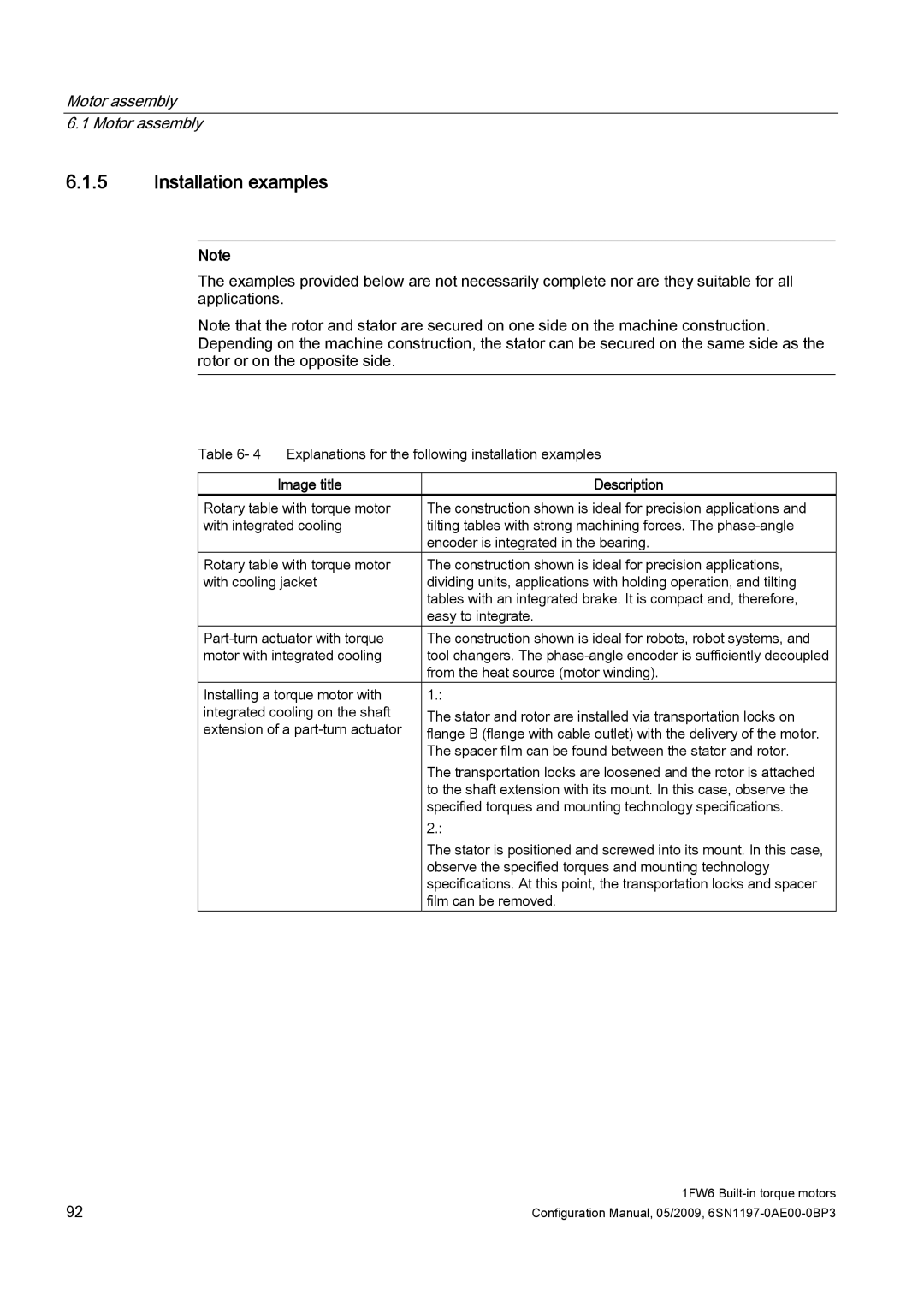

The examples provided below are not necessarily complete nor are they suitable for all applications.

Note that the rotor and stator are secured on one side on the machine construction. Depending on the machine construction, the stator can be secured on the same side as the rotor or on the opposite side.

Table 6- 4 | Explanations for the following installation examples | |

|

|

|

| Image title | Description |

Rotary table with torque motor | The construction shown is ideal for precision applications and | |

with integrated cooling | tilting tables with strong machining forces. The | |

|

| encoder is integrated in the bearing. |

Rotary table with torque motor | The construction shown is ideal for precision applications, | |

with cooling jacket | dividing units, applications with holding operation, and tilting | |

|

| tables with an integrated brake. It is compact and, therefore, |

|

| easy to integrate. |

The construction shown is ideal for robots, robot systems, and | ||

motor with integrated cooling | tool changers. The | |

|

| from the heat source (motor winding). |

Installing a torque motor with | 1.: | |

integrated cooling on the shaft | The stator and rotor are installed via transportation locks on | |

extension of a | flange B (flange with cable outlet) with the delivery of the motor. | |

|

| The spacer film can be found between the stator and rotor. |

|

| The transportation locks are loosened and the rotor is attached |

|

| to the shaft extension with its mount. In this case, observe the |

|

| specified torques and mounting technology specifications. |

|

| 2.: |

|

| The stator is positioned and screwed into its mount. In this case, |

|

| observe the specified torques and mounting technology |

|

| specifications. At this point, the transportation locks and spacer |

|

| film can be removed. |

92 | 1FW6 |

Configuration Manual, 05/2009, |