Motor components of the

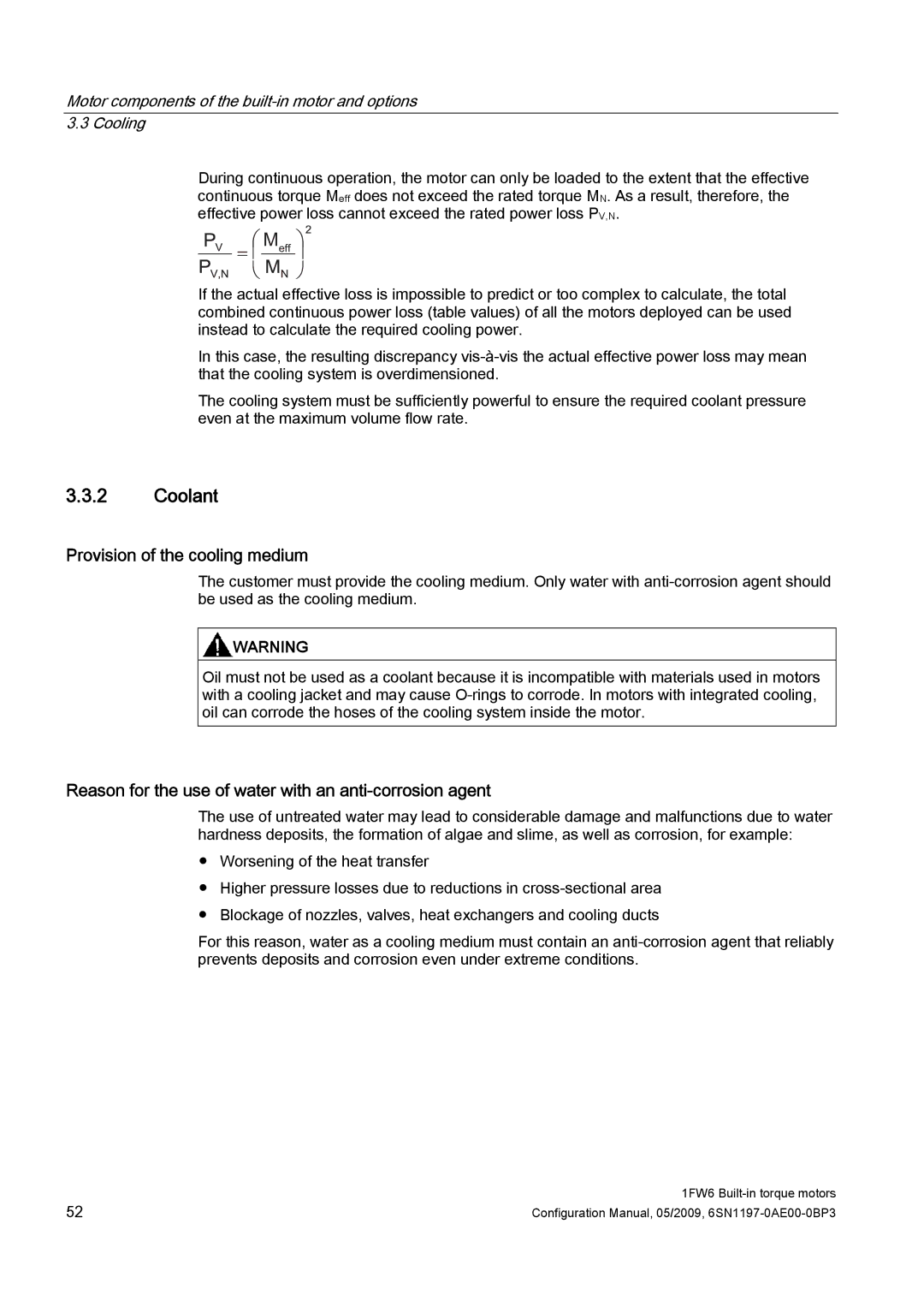

During continuous operation, the motor can only be loaded to the extent that the effective continuous torque Meff does not exceed the rated torque MN. As a result, therefore, the effective power loss cannot exceed the rated power loss PV,N.

0

⎜ HII ⎟

If the actual effective loss is impossible to predict or too complex to calculate, the total combined continuous power loss (table values) of all the motors deployed can be used instead to calculate the required cooling power.

In this case, the resulting discrepancy

The cooling system must be sufficiently powerful to ensure the required coolant pressure even at the maximum volume flow rate.

3.3.2Coolant

Provision of the cooling medium

The customer must provide the cooling medium. Only water with

![]() WARNING

WARNING

Oil must not be used as a coolant because it is incompatible with materials used in motors with a cooling jacket and may cause

Reason for the use of water with an anti-corrosion agent

The use of untreated water may lead to considerable damage and malfunctions due to water hardness deposits, the formation of algae and slime, as well as corrosion, for example:

●Worsening of the heat transfer

●Higher pressure losses due to reductions in

●Blockage of nozzles, valves, heat exchangers and cooling ducts

For this reason, water as a cooling medium must contain an

52 | 1FW6 |

Configuration Manual, 05/2009, |