Motor components of the

3.3.1Cooling circuits

Cooling circuit requirements

We recommend that the cooling circuits be designed as closed systems, to prevent the growth of algae. The maximum permissible pressure is 10 bar.

Note

We do not recommend that the cooling circuits of machines are also used to cool the motors: Due to accumulated dirt and

If the cooling circuits of the machines are also used to cool the motors, then they must fulfill all of the requirements listed here. Also note the demands on the cooling medium as well as the maximum standstill times of cooling circuits according to the specifications of the cooling medium manufacturer!

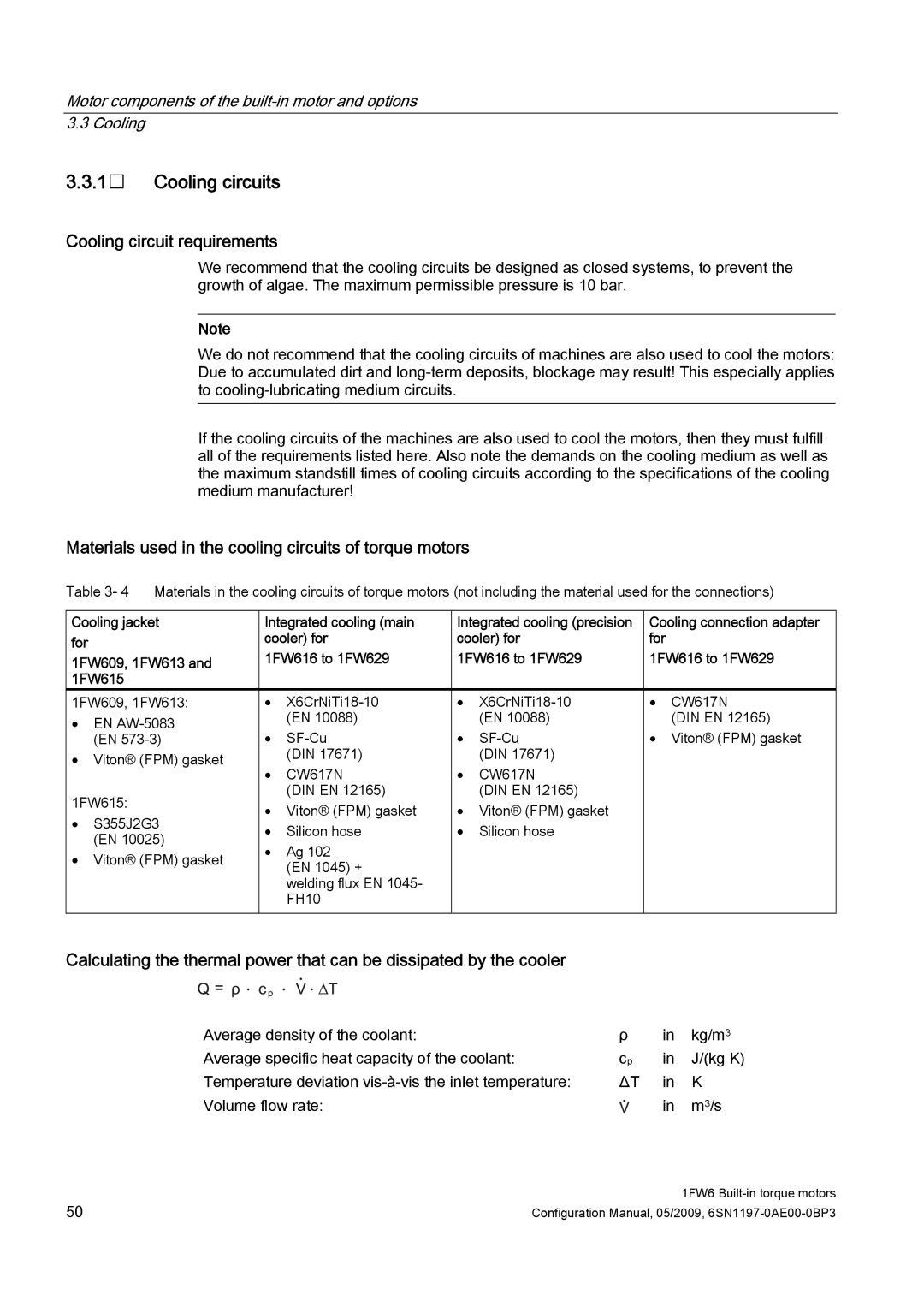

Materials used in the cooling circuits of torque motors

Table 3- 4 Materials in the cooling circuits of torque motors (not including the material used for the connections)

Cooling jacket | Integrated cooling (main | Integrated cooling (precision | Cooling connection adapter | ||||

for |

| cooler) for | cooler) for | for |

| ||

1FW609, 1FW613 and | 1FW616 to 1FW629 | 1FW616 to 1FW629 | 1FW616 to 1FW629 | ||||

1FW615 |

|

|

|

|

|

| |

1FW609, 1FW613: | ∙ | ∙ | ∙ | CW617N | |||

∙ | EN |

| (EN 10088) |

| (EN 10088) |

| (DIN EN 12165) |

| (EN | ∙ | ∙ | ∙ | Viton® (FPM) gasket | ||

∙ | Viton® (FPM) gasket |

| (DIN 17671) |

| (DIN 17671) |

|

|

∙ | CW617N | ∙ | CW617N |

|

| ||

|

|

|

| ||||

1FW615: |

| (DIN EN 12165) |

| (DIN EN 12165) |

|

| |

∙ | Viton® (FPM) gasket | ∙ | Viton® (FPM) gasket |

|

| ||

∙ | S355J2G3 |

|

| ||||

∙ | Silicon hose | ∙ | Silicon hose |

|

| ||

| (EN 10025) |

|

| ||||

| ∙ | Ag 102 |

|

|

|

| |

∙ | Viton® (FPM) gasket |

|

|

|

| ||

| (EN 1045) + |

|

|

|

| ||

|

|

|

|

|

|

| |

|

|

| welding flux EN 1045- |

|

|

|

|

|

|

| FH10 |

|

|

|

|

|

|

|

|

|

|

|

|

Calculating the thermal power that can be dissipated by the cooler

Average density of the coolant: |

| ρ | in | kg/m3 |

Average specific heat capacity of the coolant: |

| cp | in | J/(kg K) |

Temperature deviation | ΔT | in | K | |

Volume flow rate: |

|

| in | m3/s |

50 |

|

|

| 1FW6 |

Configuration Manual, 05/2009, | ||||