Motor assembly

6.1 Motor assembly

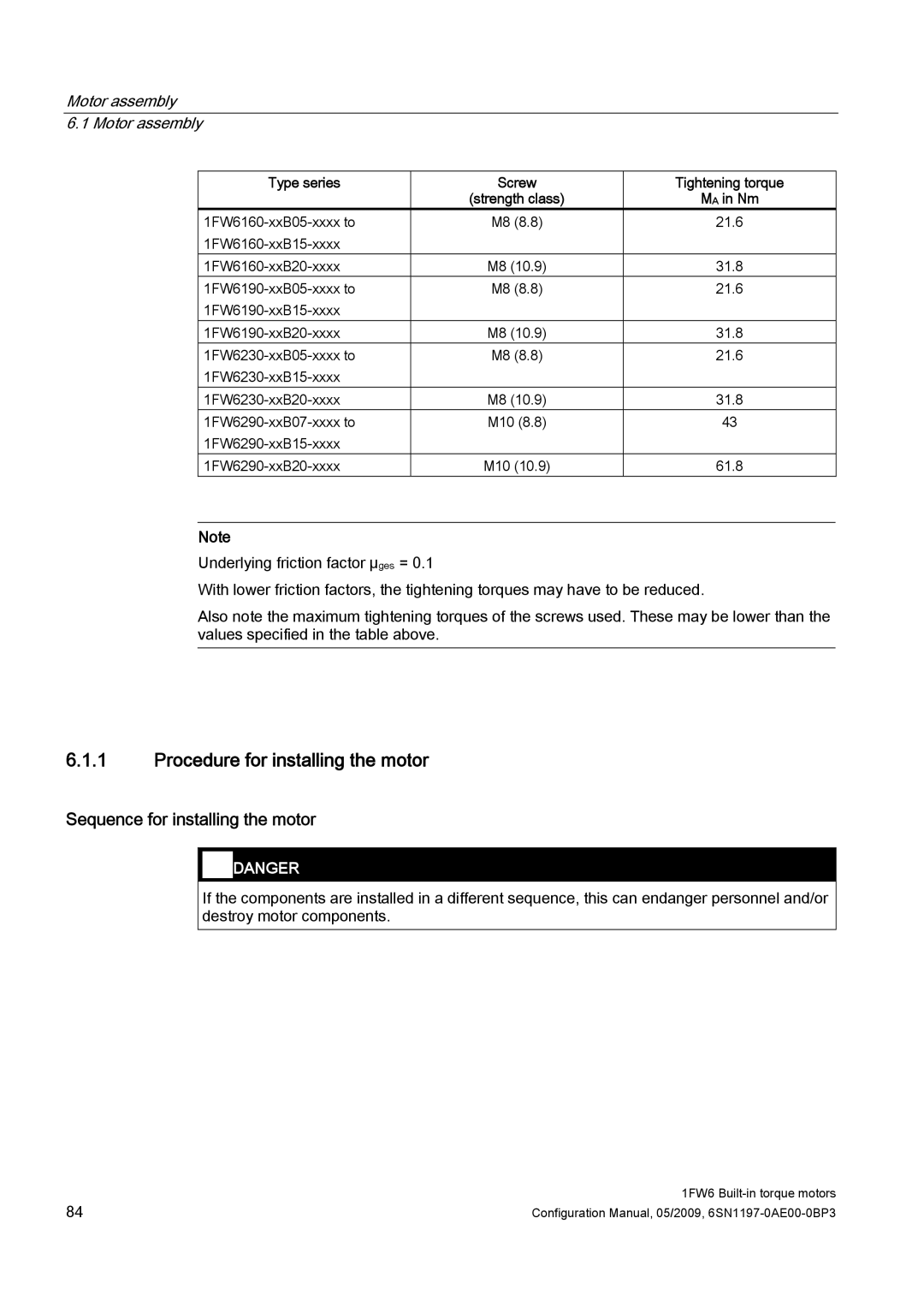

Type series | Screw | Tightening torque |

| (strength class) | MA in Nm |

M8 (8.8) | 21.6 | |

|

| |

M8 (10.9) | 31.8 | |

M8 (8.8) | 21.6 | |

|

| |

M8 (10.9) | 31.8 | |

M8 (8.8) | 21.6 | |

|

| |

M8 (10.9) | 31.8 | |

M10 (8.8) | 43 | |

|

| |

M10 (10.9) | 61.8 |

Note

Underlying friction factor µges = 0.1

With lower friction factors, the tightening torques may have to be reduced.

Also note the maximum tightening torques of the screws used. These may be lower than the values specified in the table above.

6.1.1Procedure for installing the motor

Sequence for installing the motor

![]() DANGER

DANGER

If the components are installed in a different sequence, this can endanger personnel and/or destroy motor components.

84 | 1FW6 |

Configuration Manual, 05/2009, |