Motor components of the

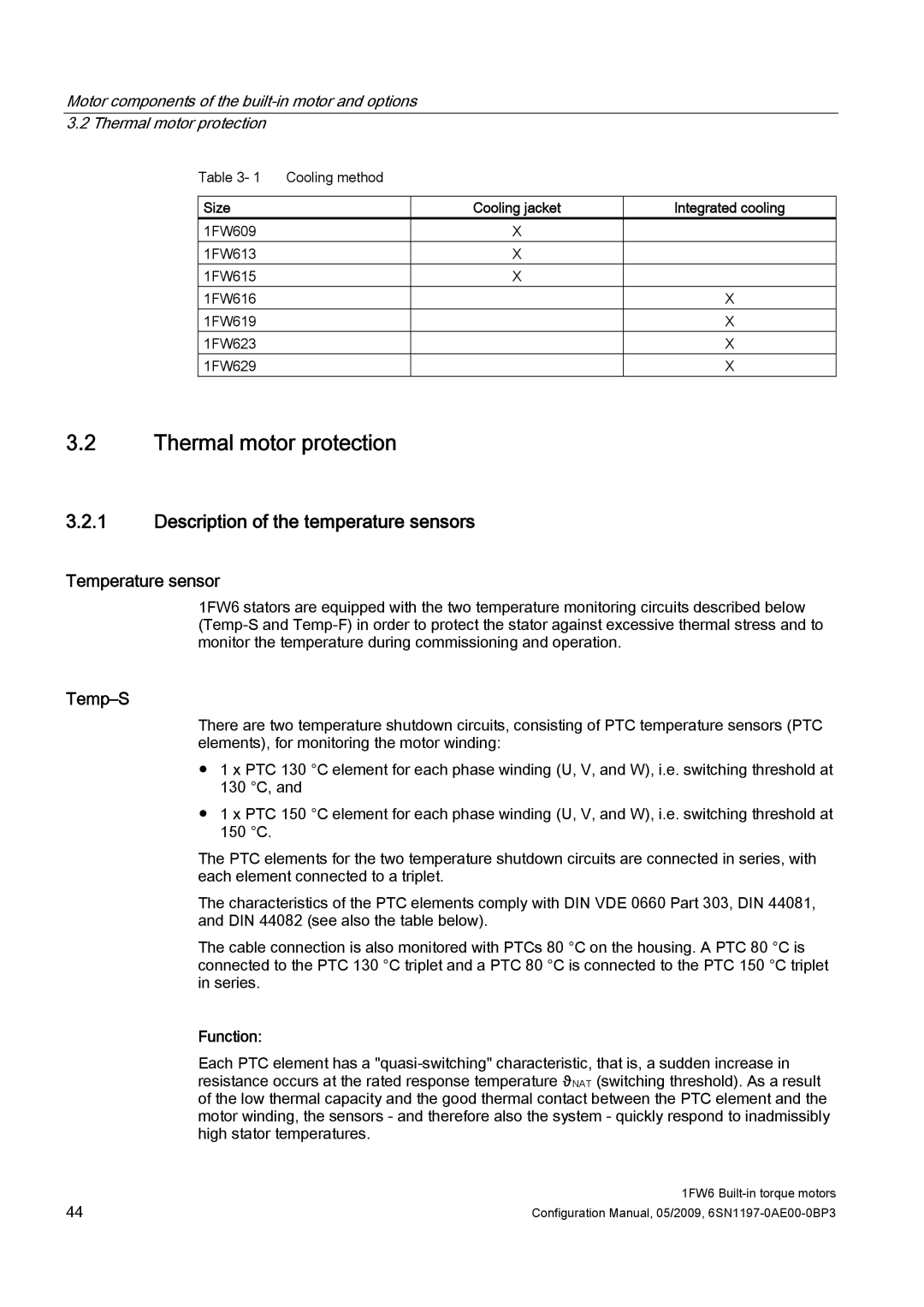

Table 3- 1 Cooling method

Size | Cooling jacket | Integrated cooling |

1FW609 | X |

|

1FW613 | X |

|

1FW615 | X |

|

1FW616 |

| X |

1FW619 |

| X |

1FW623 |

| X |

1FW629 |

| X |

3.2Thermal motor protection

3.2.1Description of the temperature sensors

Temperature sensor

1FW6 stators are equipped with the two temperature monitoring circuits described below

Temp–S

There are two temperature shutdown circuits, consisting of PTC temperature sensors (PTC elements), for monitoring the motor winding:

●1 x PTC 130 °C element for each phase winding (U, V, and W), i.e. switching threshold at 130 °C, and

●1 x PTC 150 °C element for each phase winding (U, V, and W), i.e. switching threshold at 150 °C.

The PTC elements for the two temperature shutdown circuits are connected in series, with each element connected to a triplet.

The characteristics of the PTC elements comply with DIN VDE 0660 Part 303, DIN 44081, and DIN 44082 (see also the table below).

The cable connection is also monitored with PTCs 80 °C on the housing. A PTC 80 °C is connected to the PTC 130 °C triplet and a PTC 80 °C is connected to the PTC 150 °C triplet in series.

Function:

Each PTC element has a

44 | 1FW6 |

Configuration Manual, 05/2009, |