Installation procedure

Installation procedure

Outdoor unit

Check for leakage

![]() In the case of pressure decrease during steps 1 to 3 ,check the joints with the ear,hand or soapsuds for leakage.Repair it by welding or tighten the connecting nut up.

In the case of pressure decrease during steps 1 to 3 ,check the joints with the ear,hand or soapsuds for leakage.Repair it by welding or tighten the connecting nut up.

Vacuum Pumping

![]() Use vacuum pump to evacuate the air.Never use the refrigerant for the evacuation.

Use vacuum pump to evacuate the air.Never use the refrigerant for the evacuation.

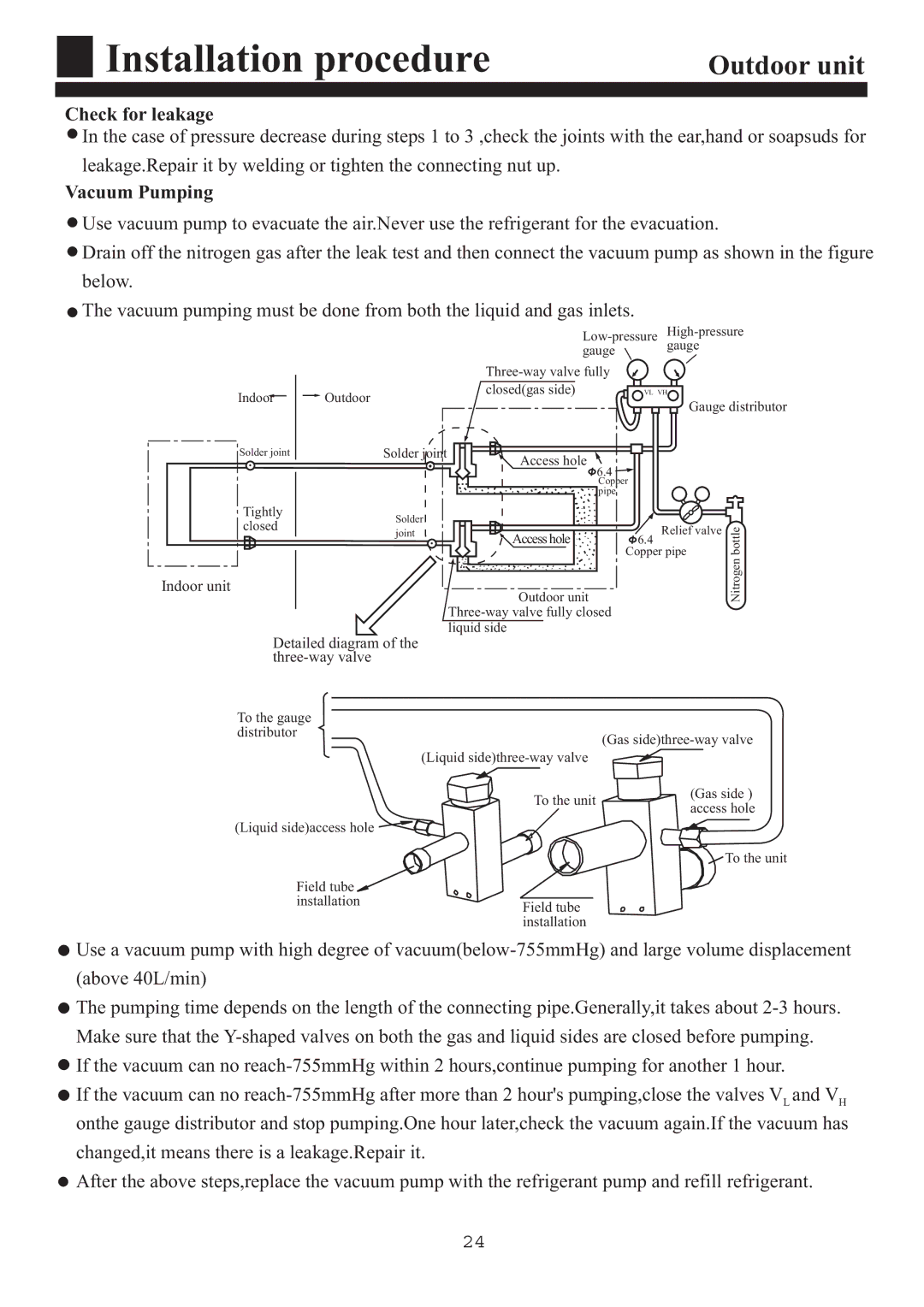

![]() Drain off the nitrogen gas after the leak test and then connect the vacuum pump as shown in the figure below.

Drain off the nitrogen gas after the leak test and then connect the vacuum pump as shown in the figure below.

![]() The vacuum pumping must be done from both the liquid and gas inlets.

The vacuum pumping must be done from both the liquid and gas inlets.

gauge gauge

|

|

| ||

Indoor | Outdoor |

| closed(gas side) | VL VH |

|

| Gauge distributor | ||

|

|

|

| |

Solder joint |

| Solder joint | Access hole |

|

|

|

| 6.4 | |

|

|

|

| Copper |

pipe

Tightly | Solder |

| |

closed |

| ||

joint | Access hole | ||

| |||

|

|

Indoor unit

Outdoor unit

Detailed diagram of the three-way valve

6.4Relief valve

Copper pipe

Nitrogen bottle

To the gauge |

|

|

distributor |

| (Gas |

|

| |

| (Liquid |

|

| To the unit | (Gas side ) |

| access hole | |

|

| |

(Liquid side)access hole |

|

|

To the unit

Field tube |

|

installation | Field tube |

| |

| installation |

![]() Use a vacuum pump with high degree of

Use a vacuum pump with high degree of

![]() The pumping time depends on the length of the connecting pipe.Generally,it takes about

The pumping time depends on the length of the connecting pipe.Generally,it takes about

![]() If the vacuum can no

If the vacuum can no

![]() If the vacuum can no

If the vacuum can no

![]() After the above steps,replace the vacuum pump with the refrigerant pump and refill refrigerant.

After the above steps,replace the vacuum pump with the refrigerant pump and refill refrigerant.

24