Lathe Safety Precautions

1.Keep fingers away from revolving parts and cutting tools while in operation.

2.Never force cutting action.

3.Never perform an abnormal or little used operation without study and use of adequate blocks, jigs, stops, and fixtures.

4.Verify proper cutting speed for the material being cut, and any special operation, in a machinery shop handbook.

5.Do not open drive cover while in operation.

6.Always remove chuck key from chuck.

7.Do not attempt to adjust or remove tools when lathe is in operation.

8.Always keep cutting tools sharp.

Cutting Procedures

The instructions that follow are basic operational procedures. It is assumed that the opera- tor understands lathe operation and it’s capabilities.

1.Rotate Turn Lever (C) counterclockwise to move the saddle outward.

2.Place the workpiece in the chuck, center, and secure with the chuck key.

3.Loosen the Straight Lever (H) and then rotate the Turn Lever (I) clockwise to engage the Dead Center tool into the end of the workpiece. Tighten Straight Lever (H) again.

4.Select the desired tool set and place it into the tool rest. Align the tool nose to the spindle centerline, then tighten.

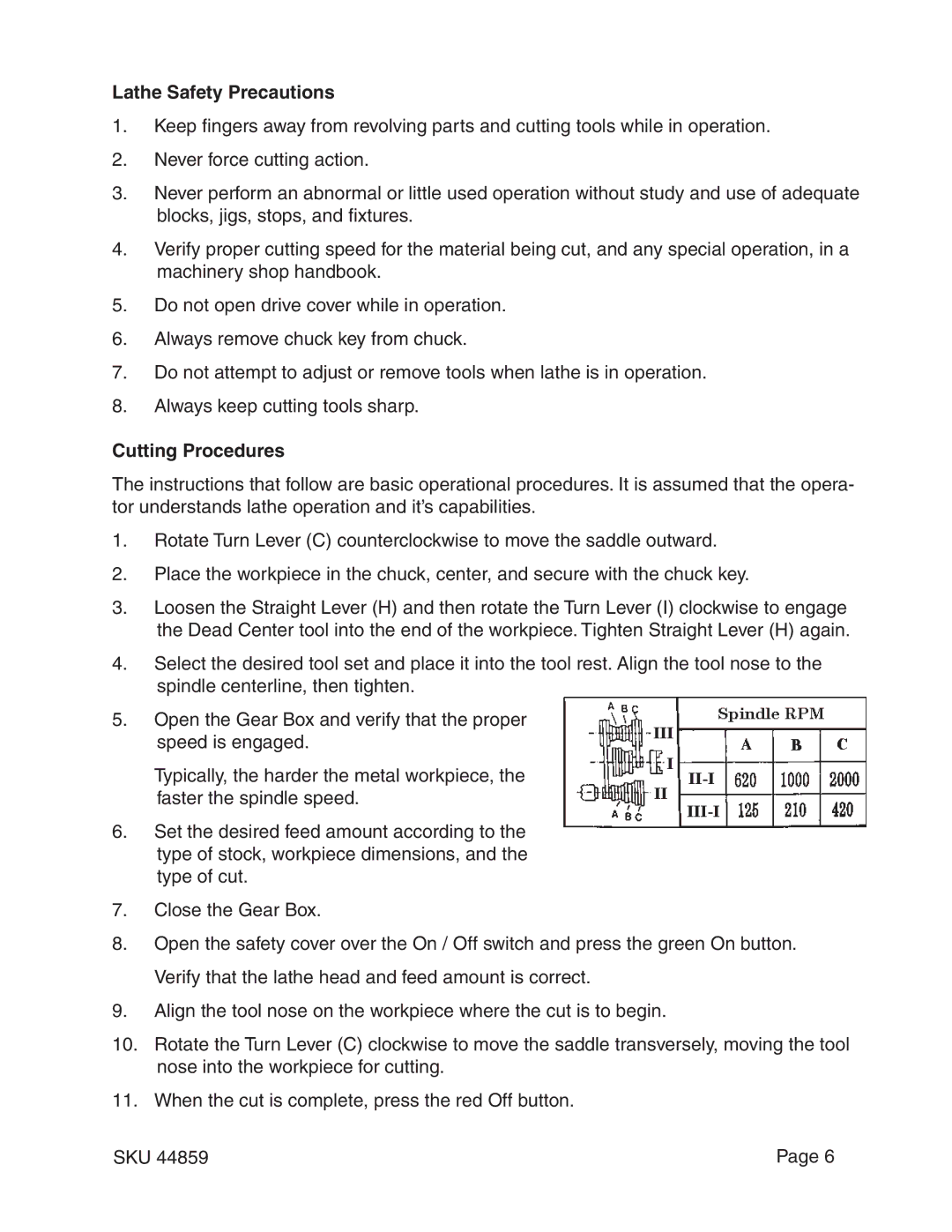

5.Open the Gear Box and verify that the proper

speed is engaged.

Typically, the harder the metal workpiece, the faster the spindle speed.

6.Set the desired feed amount according to the type of stock, workpiece dimensions, and the type of cut.

7.Close the Gear Box.

8.Open the safety cover over the On / Off switch and press the green On button. Verify that the lathe head and feed amount is correct.

9.Align the tool nose on the workpiece where the cut is to begin.

10.Rotate the Turn Lever (C) clockwise to move the saddle transversely, moving the tool nose into the workpiece for cutting.

11.When the cut is complete, press the red Off button.

SKU 44859 | Page 6 |