12 Troubleshooting

With proper installation, operation and maintenance your gas appliance will provide years of

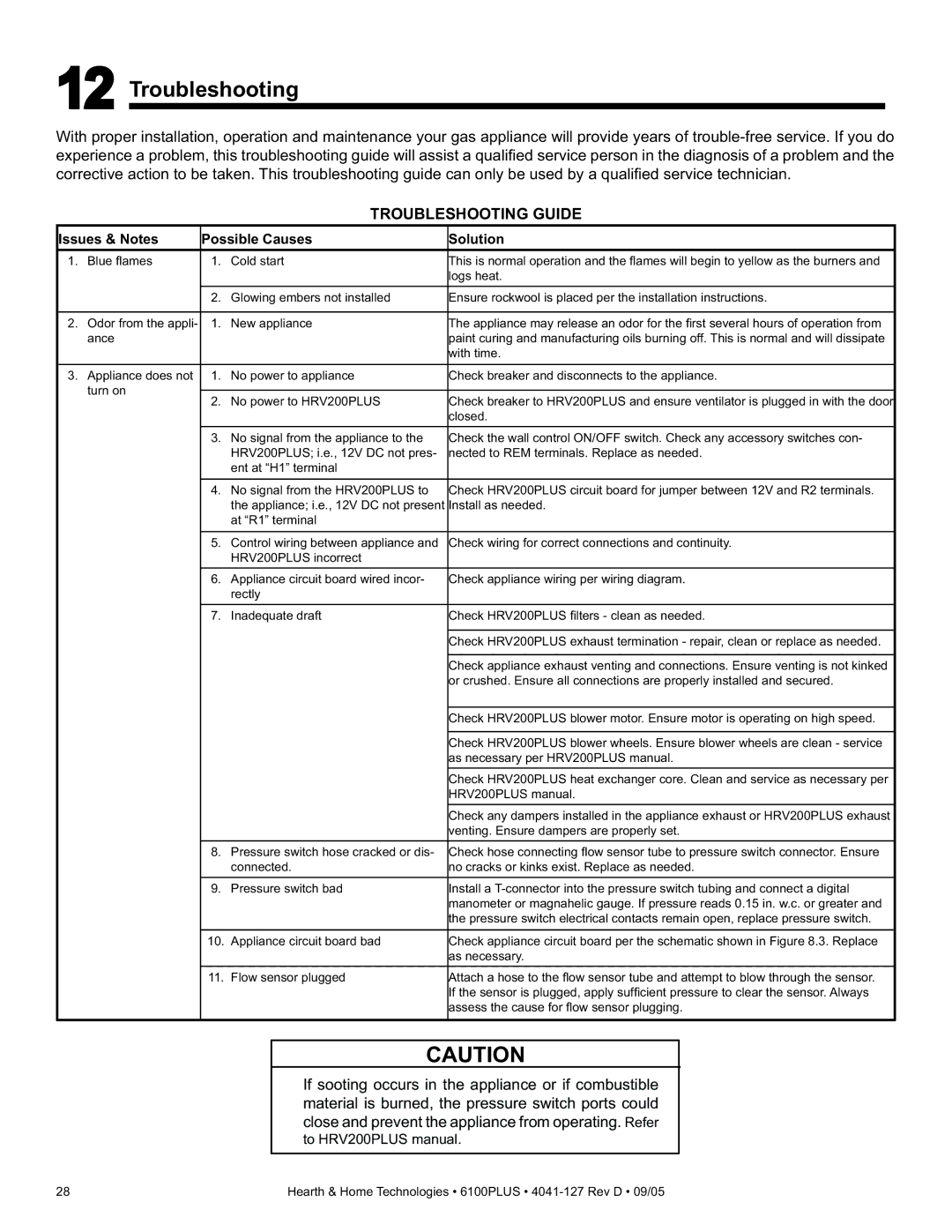

TROUBLESHOOTING GUIDE

Issues & Notes | Possible Causes | Solution | ||

1. | Blue fl ames | 1. | Cold start | This is normal operation and the fl ames will begin to yellow as the burners and |

|

|

|

| logs heat. |

|

| 2. | Glowing embers not installed | Ensure rockwool is placed per the installation instructions. |

|

|

|

| |

2. Odor from the appli- | 1. | New appliance | The appliance may release an odor for the fi rst several hours of operation from | |

| ance |

|

| paint curing and manufacturing oils burning off. This is normal and will dissipate |

|

|

|

| with time. |

|

|

|

|

|

3. | Appliance does not | 1. | No power to appliance | Check breaker and disconnects to the appliance. |

| turn on |

|

|

|

| 2. | No power to HRV200PLUS | Check breaker to HRV200PLUS and ensure ventilator is plugged in with the door | |

|

| |||

|

|

|

| closed. |

|

| 3. | No signal from the appliance to the | Check the wall control ON/OFF switch. Check any accessory switches con- |

|

|

| HRV200PLUS; i.e., 12V DC not pres- | nected to REM terminals. Replace as needed. |

|

|

| ent at “H1” terminal |

|

|

|

|

|

|

|

| 4. | No signal from the HRV200PLUS to | Check HRV200PLUS circuit board for jumper between 12V and R2 terminals. |

|

|

| the appliance; i.e., 12V DC not present | Install as needed. |

|

|

| at “R1” terminal |

|

|

| 5. | Control wiring between appliance and | Check wiring for correct connections and continuity. |

|

|

| HRV200PLUS incorrect |

|

|

| 6. | Appliance circuit board wired incor- | Check appliance wiring per wiring diagram. |

|

|

| rectly |

|

|

| 7. | Inadequate draft | Check HRV200PLUS fi lters - clean as needed. |

|

|

|

|

|

|

|

|

| Check HRV200PLUS exhaust termination - repair, clean or replace as needed. |

|

|

|

|

|

|

|

|

| Check appliance exhaust venting and connections. Ensure venting is not kinked |

|

|

|

| or crushed. Ensure all connections are properly installed and secured. |

|

|

|

|

|

|

|

|

| Check HRV200PLUS blower motor. Ensure motor is operating on high speed. |

|

|

|

|

|

|

|

|

| Check HRV200PLUS blower wheels. Ensure blower wheels are clean - service |

|

|

|

| as necessary per HRV200PLUS manual. |

|

|

|

| Check HRV200PLUS heat exchanger core. Clean and service as necessary per |

|

|

|

| HRV200PLUS manual. |

|

|

|

| Check any dampers installed in the appliance exhaust or HRV200PLUS exhaust |

|

|

|

| venting. Ensure dampers are properly set. |

|

| 8. | Pressure switch hose cracked or dis- | Check hose connecting fl ow sensor tube to pressure switch connector. Ensure |

|

|

| connected. | no cracks or kinks exist. Replace as needed. |

|

| 9. | Pressure switch bad | Install a |

|

|

|

| manometer or magnahelic gauge. If pressure reads 0.15 in. w.c. or greater and |

|

|

|

| the pressure switch electrical contacts remain open, replace pressure switch. |

|

|

|

|

|

|

| 10. | Appliance circuit board bad | Check appliance circuit board per the schematic shown in Figure 8.3. Replace |

|

|

|

| as necessary. |

|

| 11. | Flow sensor plugged | Attach a hose to the fl ow sensor tube and attempt to blow through the sensor. |

|

|

|

| If the sensor is plugged, apply suffi cient pressure to clear the sensor. Always |

|

|

|

| assess the cause for fl ow sensor plugging. |

|

|

|

|

|

CAUTION

If sooting occurs in the appliance or if combustible material is burned, the pressure switch ports could close and prevent the appliance from operating. Refer to HRV200PLUS manual.

28 | Hearth & Home Technologies • 6100PLUS • |