Mode D’EMPLOI ET Instructions DE Securite

Contents

Motor SAW

Product Specifications

English

Power Tool Safety

Table SAW Safety

Power Supply Requirements

Electrical Requirements and Safety

Extension Cord Requirements Grounding Instructions

Guidelines for Extension Cords

Tools Needed for Assembly

Accessories and Attachments

Carton Contents

Unpacking Your Jobsite Table SAW

Know Your Jobsite Table SAW

Table SAW Terms

Glossary of Terms

Woodworking Terms

Blade Elevation Handwheel Raises

Installing and Removing the Blade FIG. D

Assembly and Adjustments

Blade Tilting Handwheel FIG. C

Blade Raising Handwheel FIG. B

Fig. E

Blade Guard Assembly FIG. G, H

Stop

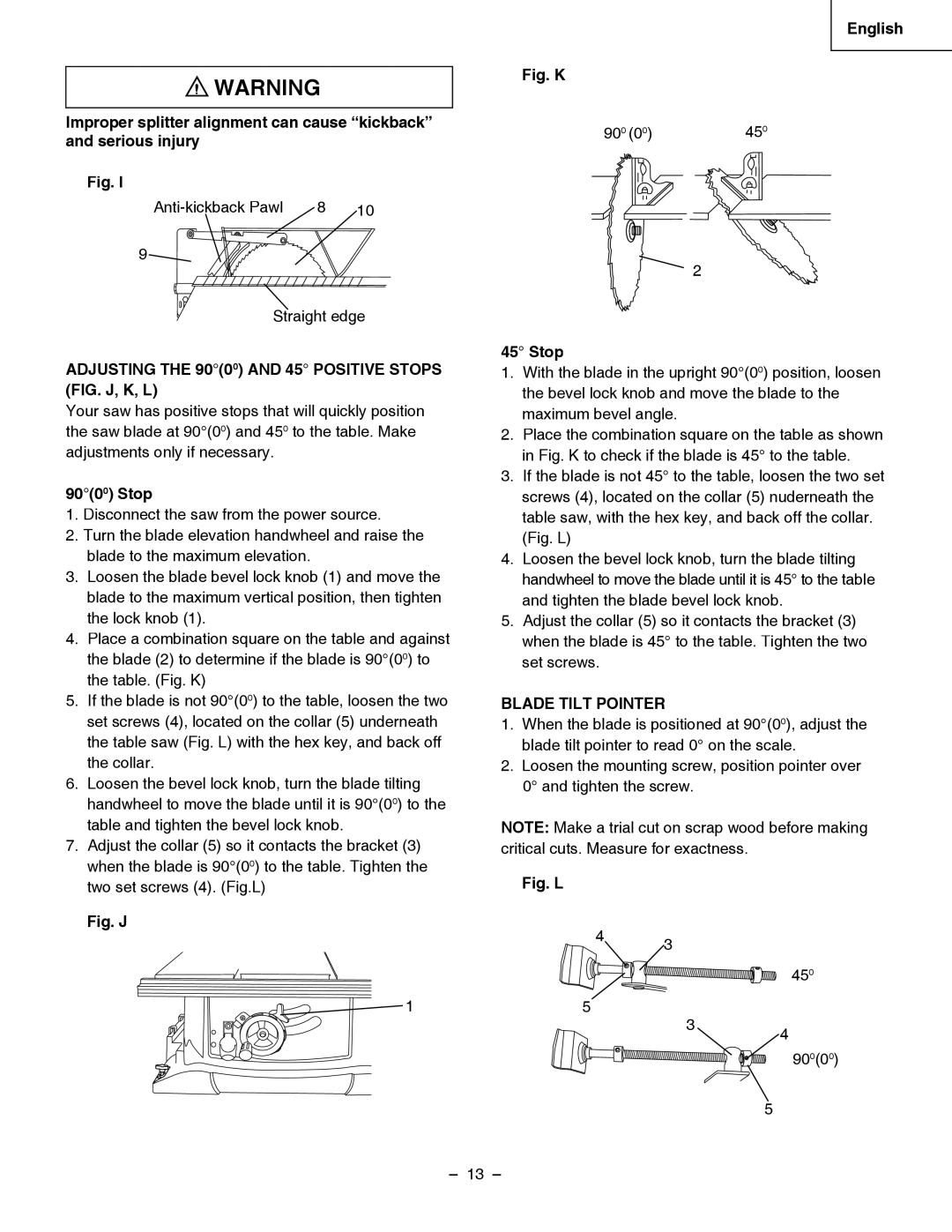

Adjusting the 9000 and 45 Positive Stops FIG. J, K, L

Blade Tilt Pointer

If the blade is partial to left side

Blade Parallel to the Miter Gauge Groove FIG. M, N

Storage FIG. O, P

Rip fence and miter gauge Fig. O

RIP Fence Adjustment FIG. S

Miter Gauge Adjustment FIG. Q

Blade Fig. P

Miter Gauge Operation FIG. Q

Adjusting the Cutting Line Indicator FIG. U

RIP Fence Indicator FIG. T

Adjusting CAM Locking Lever FIG

Table Extension Scale Pointer FIG. T-1

Basic SAW Operations

Operation

Ripping FIG. AA, BB

Cutting Operations

Ripping Small Pieces

Bevel Ripping

Crosscutting FIG. CC

Bevel Crosscutting FIG. EE

Compound Miter Crosscutting FIG. FF

Using Wood Facing on the RIP Fence FIG. HH

Auxiliary Fence FIG

Miter Cuts FIG. GG

Dado Cuts FIG. KK

Fig. JJ

General Maintenance

Maintenance

Maintaining Your Table SAW

Blade Raising and Tilting Mechanism FIG. LL

Symptom Possible Causes Corrective Action

Troubleshooting Guide

Push Stick Construction

Français

Specifications Produit

Moteur

Scie

Avertissement

Consignes DE Sécurité SUR LES Outils

Consignes DE Sécurité SUR LA Scie À Table

Exigences Concernant L’ Alimentation Électrique

Exigences Électriques ET Sécurité

Exigences Concernant LES Rallonges

Directives Concernant LES Rallonges

Outils Requis Pour Assemblage

Accessoires

Contenu DE LA Boîte

Déballage DE LA Scie À Table DE Chantier

Apprendre À Connaître LA Scie À Table DE Chantier

Termes Relatifs À LA Scie À Table Qualité PRO Craftsman

Glossaire

Termes DE Menuiserie

Assemblage ET Réglages

Installation ET Remplacement DE LA Lame FIG. D

Manivelle D’INCLINAISON DE LA Lame FIG. C

Manivelle D’ELEVATION DE LA Lame FIG. B

Montage DU Protecteur DE Lame FIG. G, H

Fig. F

Réglage DES Butées Fixes À 9000 ET 45 FIG. J, K, L

Provoquer un retour et des blessures graves

Butée

Indicateur D’INCLINAISON DE Lame

Si la lame est partiellement à gauche

Lame Parallèle À LA Rainure DE LA Jauge À Onglets FIG. M, N

Rangement FIG. O, P

Guide de refente et jauge à onglets Fig. O

Reglage DU Guide DE Coupe DE FIL FIG. Q

Lame Fig. P

Utilisation DU Guide DE Coupe D’ONGLET FIG. Q

Reglage DU Guide DE Coupe DE FIL FIG. S

Fig. T-1 Reglage DE L’INDICATEUR DE Ligne DE Coupe Fig. U

Indicateur D’ÉCHELLE DE Rallonge DE Table FIG. T-1

Fonctions DE Base DE LA Scie

Utilisation

Sciage EN Long FIG.AA, BB

Opérations DE Coupe

Coupe EN Long DE Petites Pièces

Coupe EN Long EN Biseau

Tronçonnage FIG.CC

Tronçonnage EN Biseau FIG. EE

Coupes D’ONGLET FIG. GG

Coupe Transversale D’ONGLET DE Type Mixte FIG. FF

Guide Auxiliaire FIG

Rainurage FIG. KK

Avec deux attaches C. Fig. JJ

Entretien DE LA Scie À Table

Entretien

Entretien Général

Lubrification

Problème Causes Possibles Mesures Correctives

Guide DE Dépannage

Fabrication D’UN Poussoir

Español

Especificaciones DEL Producto

Motor Siera

Seguridad DE LA Herramienta Eléctrica

Seguridad EN EL Manejo DE LA Sierra DE Mesa

Requisitos DE LA Fuente Dealimentación

Requisitos Electricos Y Seguridad

Requisitos DE LOS Cablesprolongadores

Indicaciones Para LOS Cablesprolongadores

Contenido DE LA Caja

Accesorios Y Acoples

Cómo Desempacar SU Sierra DE Mesa Para EL Lugar DE Trabajo

La parte trasera de la sierra de mesa

Términos DE LA Sierra DE Mesa

Glosario DE Terminos

Terminos DE Carpinteria

Interruptor DE Reinicio POR Sobrecarga

Manivela DE Inclinación DE LA Hoja FIG. C

Montaje Y Ajustes

Instalación Y Cambio DE LA Hoja FIG. D

Manivela DE Elevación DE LA Hoja FIG. B

Conjunto Protector DE Hoja FIG. G, H

Graves

Provocar un retroceso de la herramienta y heridas

Ajuste DE LAS Paradas Positivas DE 900 Y 45 FIG. J, K, L

Parada a

Fig. O Arrollamiento de los cables Fig. O-1

Almacenaje FIG. O, P

Ajuste DE LA Guía DE Ingletes FIG. Q

Español Hoja Fig. P

Funcionamiento DE LA Guía DE Ingletes FIG.Q

Ajuste DEL SEPARADOR-LIMITADOR FIG. S

Ajuste EL Indicador DE Línea DEL Corte FIG. U

Indicador DE LA Escala DE Extensión DE LA Mesa FIG. T-1

Cómo Ajustar LA Palanca DE Bloqueo DE LA Leva FIG

Funcionamiento Elemental DE LA Sierra

Funcionamiento

Corte EN Direccion a LA Veta FIG. AA, BB

Operaciones DE Corte

Corte AL Hilo DE Piezas Pequeñas

Corte AL Hilo EN Bisel

Corte Transversal FIG.CC

USO DE Caras DE Madera EN LA Guía DE Ingletes FIG. DD

Tope Auxiliar FIG

Corte Compuesto DE Ingletes FIG. FF

Fabricación del lateral

Union DE Inglete FIG. GG

Cortes DE Ranura FIG. KK

En forma de C. Fig. JJ

Mantenimiento DE LA Sierra DE Mesa

Mantenimiento

Mantenimiento General

Mecanismo DE Elevación E Inclinación DE LA Hoja FIG. LL

Problema Causas DEL Problema Solucion

Guia Para LA Solucion DE Problemas

Construccion DEL Empujador

Parts List for Schematic

Parts List

Jobsite Table SAW Model NO. C10RA3

Always order by I.D. Number

Jobsite Table SAW Model NO. C10RA3

QTY

Jobsite Table SAW Model NO. C10RA3 Part List for Stand

Hitachi Koki Canada Co

![]() WARNING

WARNING![]()

![]()

![]() 1

1