English

MAINTENANCE AND INSPECTION

![]() CAUTION: Pull out battery before doing any inspection or maintenance.

CAUTION: Pull out battery before doing any inspection or maintenance.

1.Inspecting the saw blade:

Since use of a dull saw blade will degrade efficiency and cause possible motor malfunction, sharpen or replace the saw blade as soon as abrasion is noted.

![]() CAUTION:

CAUTION:

If a dull saw blade is used, reactive force is increased during cutting operation. Avoid the use of the dull saw blade without repair.

2.Check the mounting screws

Loose mounting screws are dangerous. Regularly inspect them and make sure they are tight.

![]() CAUTION: Using this power tool with loosen, screws is extremely dangerous.

CAUTION: Using this power tool with loosen, screws is extremely dangerous.

3.Performance checkup and maintenance of safety cover

Keep the safety cover in good shape for smooth performance at all times. Be sure to make prompt repair in case of any malfunction.

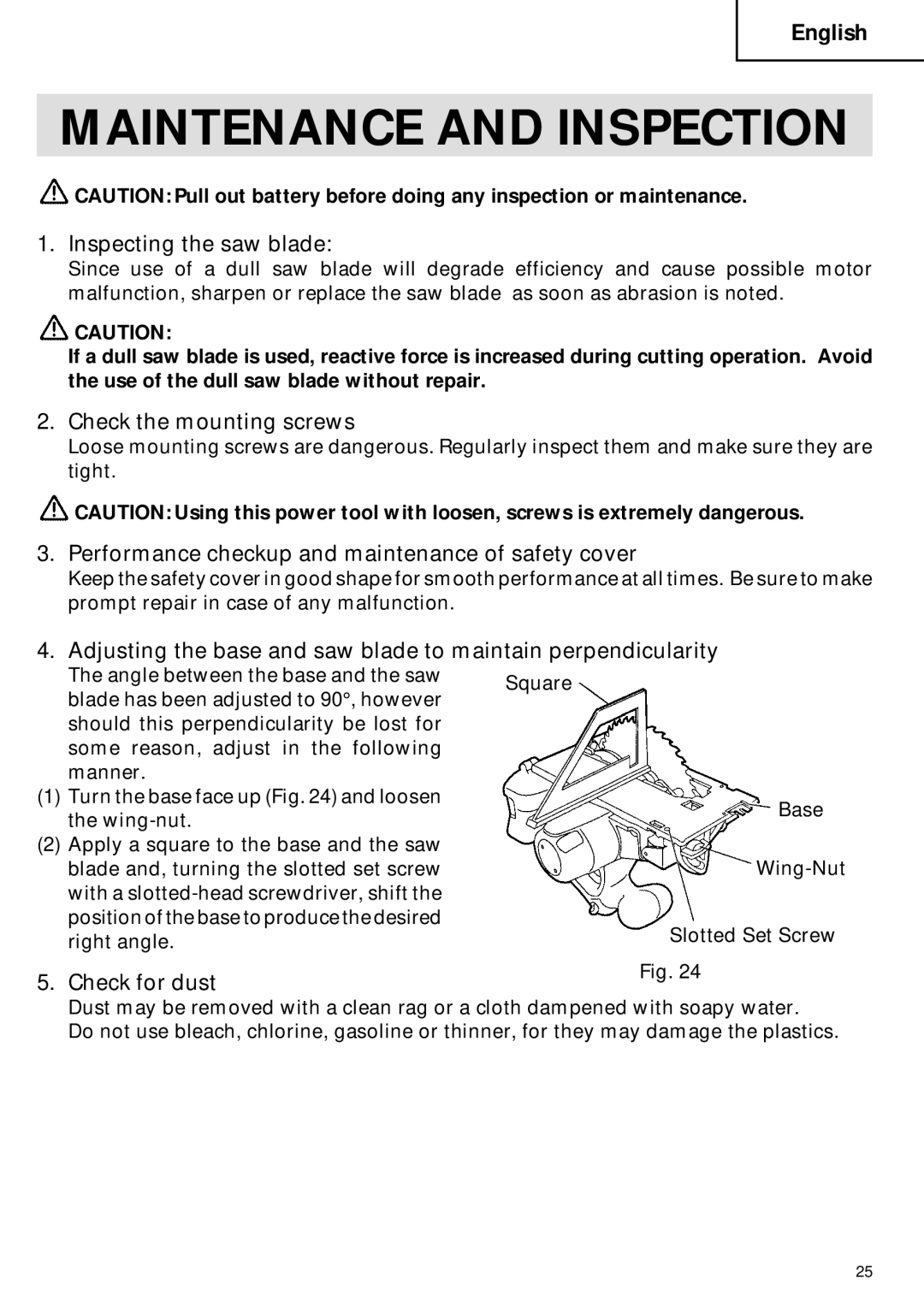

4.Adjusting the base and saw blade to maintain perpendicularity

The angle between the base and the saw | Square | |

blade has been adjusted to 90°, however | ||

| ||

should this perpendicularity be lost for |

| |

some reason, adjust in the following |

| |

manner. |

|

(1)Turn the base face up (Fig. 24) and loosen the

(2)Apply a square to the base and the saw blade and, turning the slotted set screw with a

5. Check for dust

Base

Slotted Set Screw

Fig. 24

Dust may be removed with a clean rag or a cloth dampened with soapy water.

Do not use bleach, chlorine, gasoline or thinner, for they may damage the plastics.

25