English

NOTE:

Do not use core bits 25 mm or 29 mm.

(2) Core bit

⬤External dia. 25, 29, 32, 35, 38, 45, 54, 64, 79, 94, 105 mm

(with guide plate, not applicable to cores 25 mm or 29 mm)

(3) Core bit shank

⬤Applied to core bits above 38 mm

⬤Applied to core bits below 35 mm

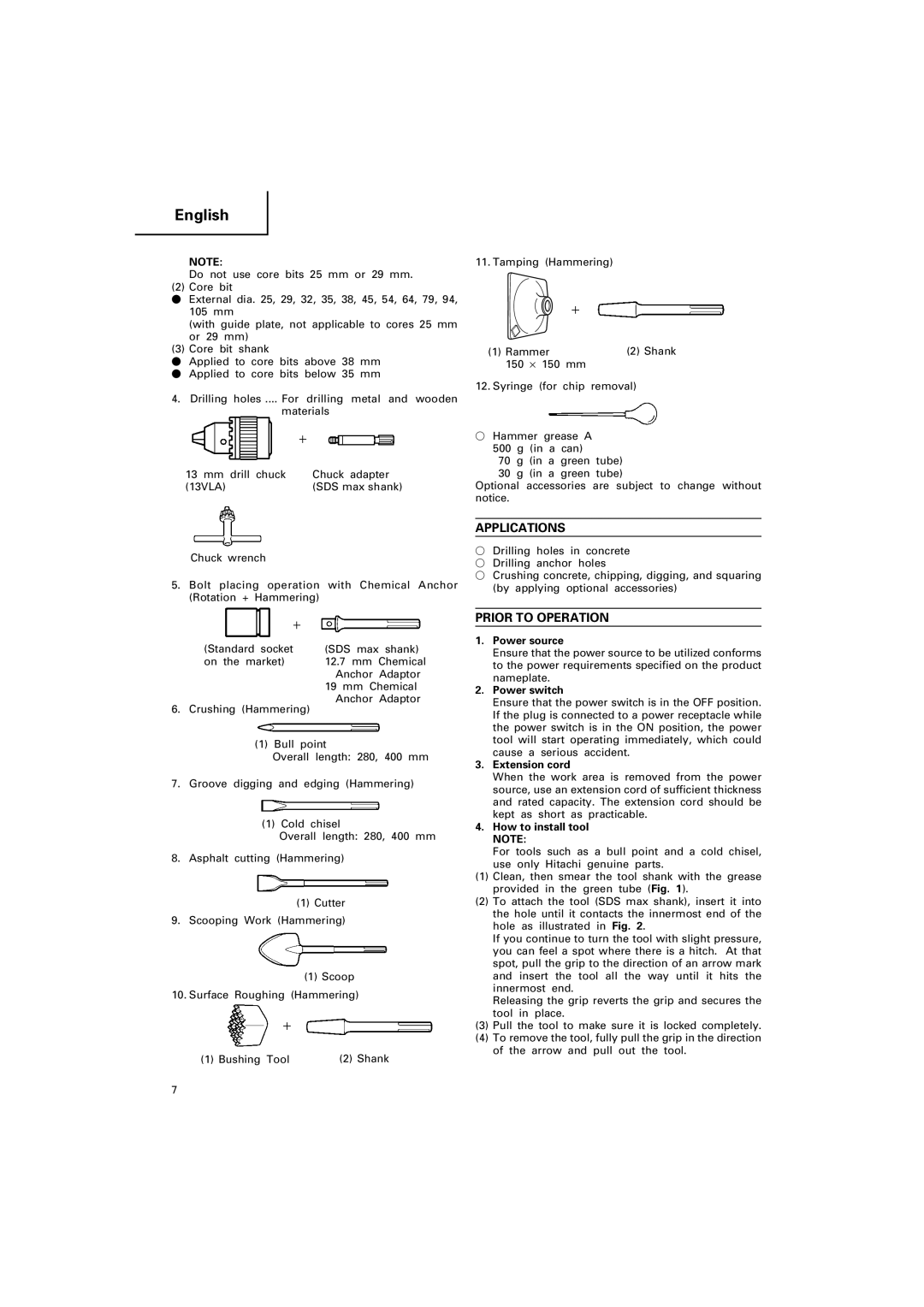

4.Drilling holes .... For drilling metal and wooden materials

13 mm drill chuck | Chuck adapter |

(13VLA) | (SDS max shank) |

11. Tamping (Hammering)

(1) Rammer | (2) Shank |

150 ⋅ 150 mm |

|

12. Syringe (for chip removal)

◯Hammer grease A 500 g (in a can)

70 g (in a green tube)

30 g (in a green tube)

Optional accessories are subject to change without notice.

APPLICATIONS

Chuck wrench | ◯ Drilling | holes in concrete | |

◯ Drilling | anchor holes | ||

| |||

5. Bolt placing operation with Chemical Anchor | ◯ Crushing concrete, chipping, digging, and squaring | ||

(by applying optional accessories) | |||

(Rotation + Hammering) |

|

| |

(Standard socket | (SDS max shank) |

on the market) | 12.7 mm Chemical |

| Anchor Adaptor |

| 19 mm Chemical |

| Anchor Adaptor |

6.Crushing (Hammering)

(1)Bull point

Overall length: 280, 400 mm

7. Groove digging and edging (Hammering)

(1) Cold chisel

Overall length: 280, 400 mm

8.Asphalt cutting (Hammering)

(1)Cutter

9.Scooping Work (Hammering)

(1)Scoop

10.Surface Roughing (Hammering)

(1) Bushing Tool | (2) Shank |

PRIOR TO OPERATION

1.Power source

Ensure that the power source to be utilized conforms to the power requirements specified on the product nameplate.

2.Power switch

Ensure that the power switch is in the OFF position. If the plug is connected to a power receptacle while the power switch is in the ON position, the power tool will start operating immediately, which could cause a serious accident.

3.Extension cord

When the work area is removed from the power source, use an extension cord of sufficient thickness and rated capacity. The extension cord should be kept as short as practicable.

4.How to install tool

NOTE:

For tools such as a bull point and a cold chisel, use only Hitachi genuine parts.

(1)Clean, then smear the tool shank with the grease provided in the green tube (Fig. 1).

(2)To attach the tool (SDS max shank), insert it into the hole until it contacts the innermost end of the hole as illustrated in Fig. 2.

If you continue to turn the tool with slight pressure, you can feel a spot where there is a hitch. At that spot, pull the grip to the direction of an arrow mark and insert the tool all the way until it hits the innermost end.

Releasing the grip reverts the grip and secures the tool in place.

(3)Pull the tool to make sure it is locked completely.

(4)To remove the tool, fully pull the grip in the direction of the arrow and pull out the tool.

7