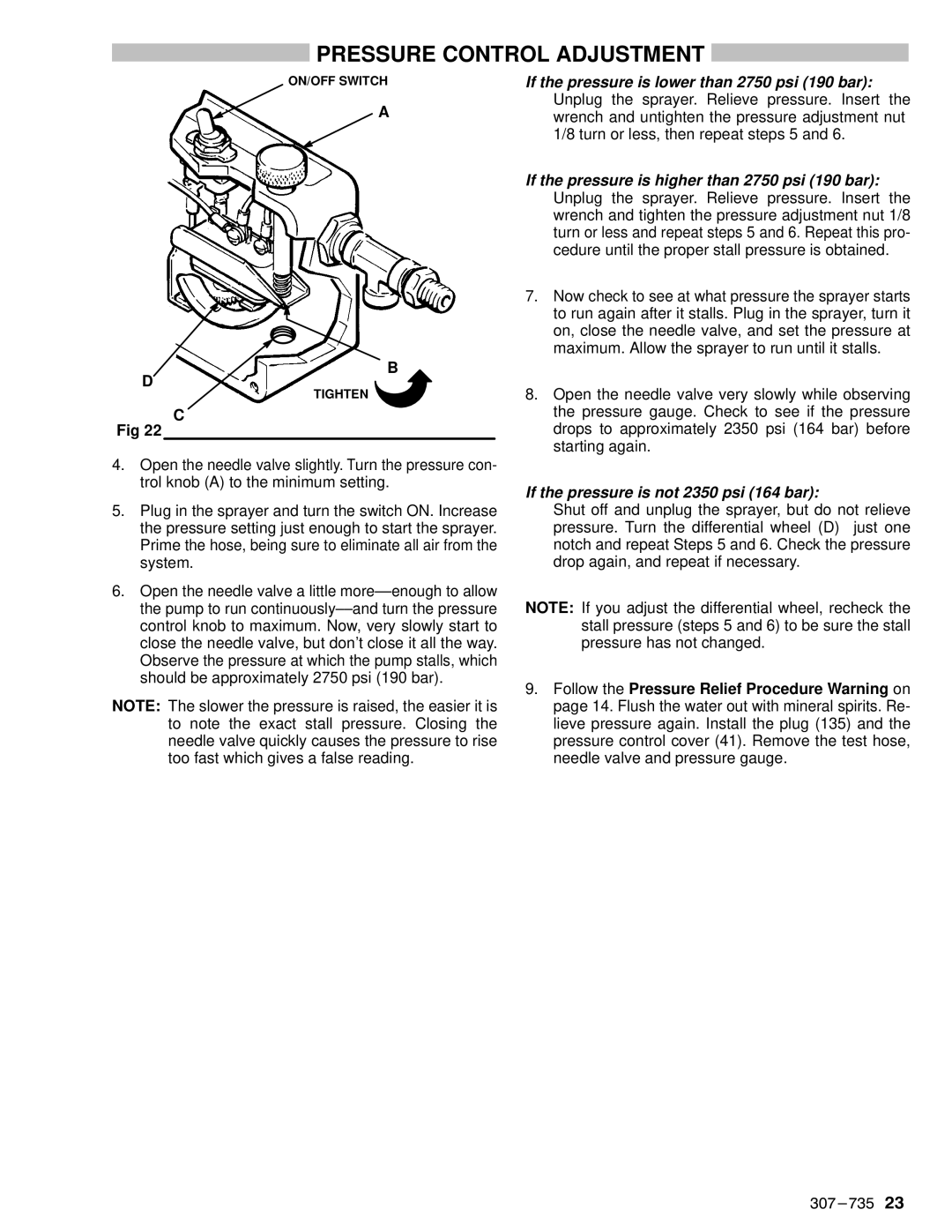

PRESSURE CONTROL ADJUSTMENT

ON/OFF SWITCH

A

B

D

TIGHTEN

C

Fig 22

4.Open the needle valve slightly. Turn the pressure con- trol knob (A) to the minimum setting.

5.Plug in the sprayer and turn the switch ON. Increase the pressure setting just enough to start the sprayer. Prime the hose, being sure to eliminate all air from the system.

6.Open the needle valve a little more±±enough to allow the pump to run continuously±±and turn the pressure control knob to maximum. Now, very slowly start to close the needle valve, but don't close it all the way. Observe the pressure at which the pump stalls, which should be approximately 2750 psi (190 bar).

NOTE: The slower the pressure is raised, the easier it is to note the exact stall pressure. Closing the needle valve quickly causes the pressure to rise too fast which gives a false reading.

If the pressure is lower than 2750 psi (190 bar): Unplug the sprayer. Relieve pressure. Insert the wrench and untighten the pressure adjustment nut 1/8 turn or less, then repeat steps 5 and 6.

If the pressure is higher than 2750 psi (190 bar): Unplug the sprayer. Relieve pressure. Insert the wrench and tighten the pressure adjustment nut 1/8 turn or less and repeat steps 5 and 6. Repeat this pro- cedure until the proper stall pressure is obtained.

7.Now check to see at what pressure the sprayer starts to run again after it stalls. Plug in the sprayer, turn it on, close the needle valve, and set the pressure at maximum. Allow the sprayer to run until it stalls.

8.Open the needle valve very slowly while observing the pressure gauge. Check to see if the pressure drops to approximately 2350 psi (164 bar) before starting again.

If the pressure is not 2350 psi (164 bar):

Shut off and unplug the sprayer, but do not relieve pressure. Turn the differential wheel (D) just one notch and repeat Steps 5 and 6. Check the pressure drop again, and repeat if necessary.

NOTE: If you adjust the differential wheel, recheck the stall pressure (steps 5 and 6) to be sure the stall pressure has not changed.

9.Follow the Pressure Relief Procedure Warning on page 14. Flush the water out with mineral spirits. Re- lieve pressure again. Install the plug (135) and the pressure control cover (41). Remove the test hose, needle valve and pressure gauge.