English

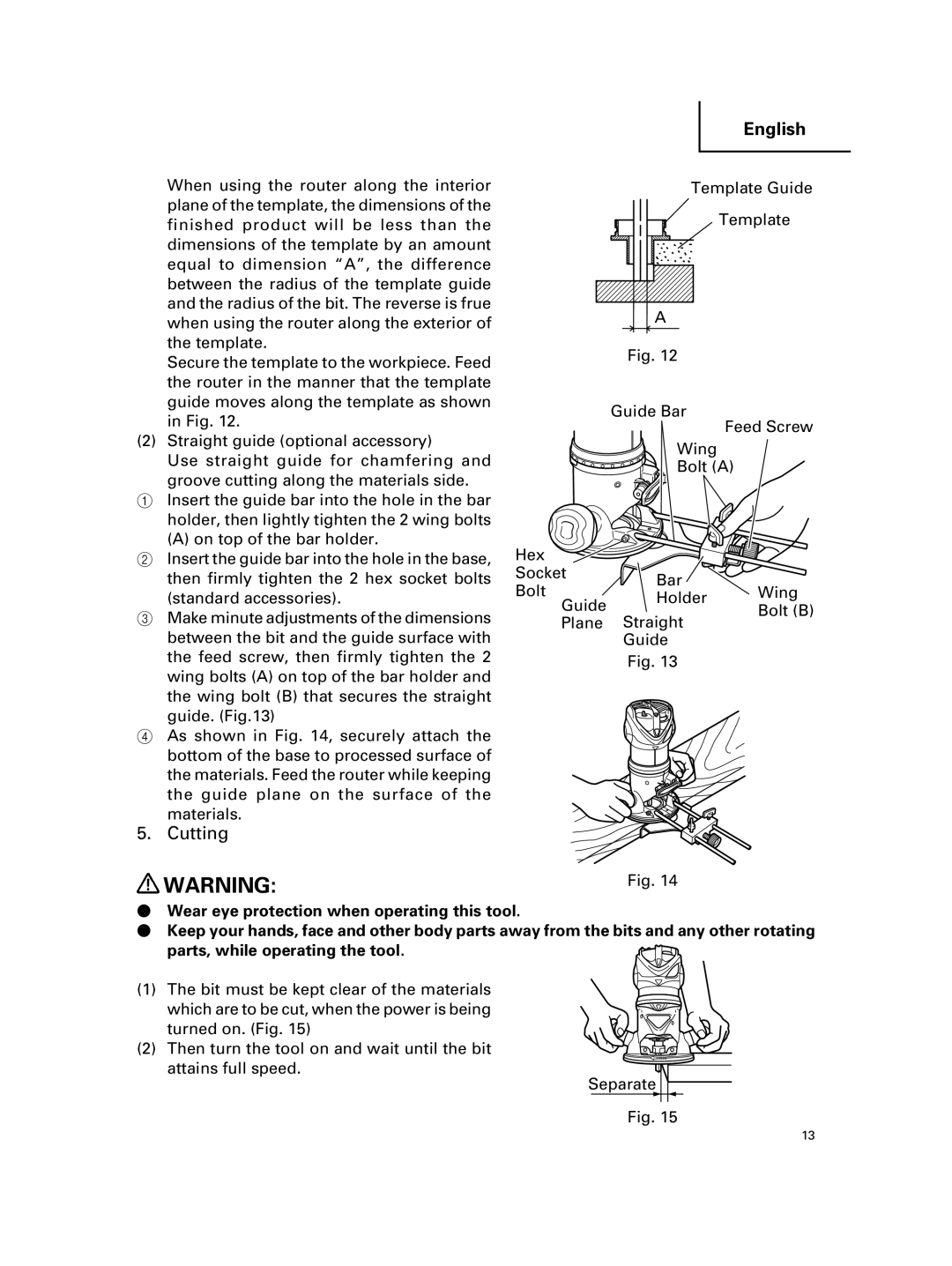

When using the router along the interior plane of the template, the dimensions of the finished product will be less than the dimensions of the template by an amount equal to dimension “A”, the difference between the radius of the template guide and the radius of the bit. The reverse is frue when using the router along the exterior of the template.

Secure the template to the workpiece. Feed the router in the manner that the template guide moves along the template as shown in Fig. 12.

(2)Straight guide (optional accessory)

Use straight guide for chamfering and

groove cutting along the materials side.

1Insert the guide bar into the hole in the bar

holder, then lightly tighten the 2 wing bolts

(A) on top of the bar holder.

2Insert the guide bar into the hole in the base,

then firmly tighten the 2 hex socket bolts (standard accessories).

3Make minute adjustments of the dimensions between the bit and the guide surface with the feed screw, then firmly tighten the 2 wing bolts (A) on top of the bar holder and the wing bolt (B) that secures the straight

guide. (Fig.13)

4As shown in Fig. 14, securely attach the bottom of the base to processed surface of the materials. Feed the router while keeping the guide plane on the surface of the

materials.

5. Cutting

Template Guide

Template

A

Fig. 12

Guide Bar

Feed Screw

Wing

Bolt (A)

Hex |

|

| |

Socket | Bar |

| |

Bolt | Wing | ||

Holder | |||

Guide | Bolt (B) | ||

Straight | |||

Plane | |||

| |||

| Guide |

| |

| Fig. 13 |

|

WARNING: | Fig. 14 |

⬤Wear eye protection when operating this tool.

⬤Keep your hands, face and other body parts away from the bits and any other rotating

parts, while operating the tool.

(1) The bit must be kept clear of the materials

which are to be cut, when the power is being turned on. (Fig. 15)

(2) Then turn the tool on and wait until the bit

attains full speed.

Separate

Fig. 15

13