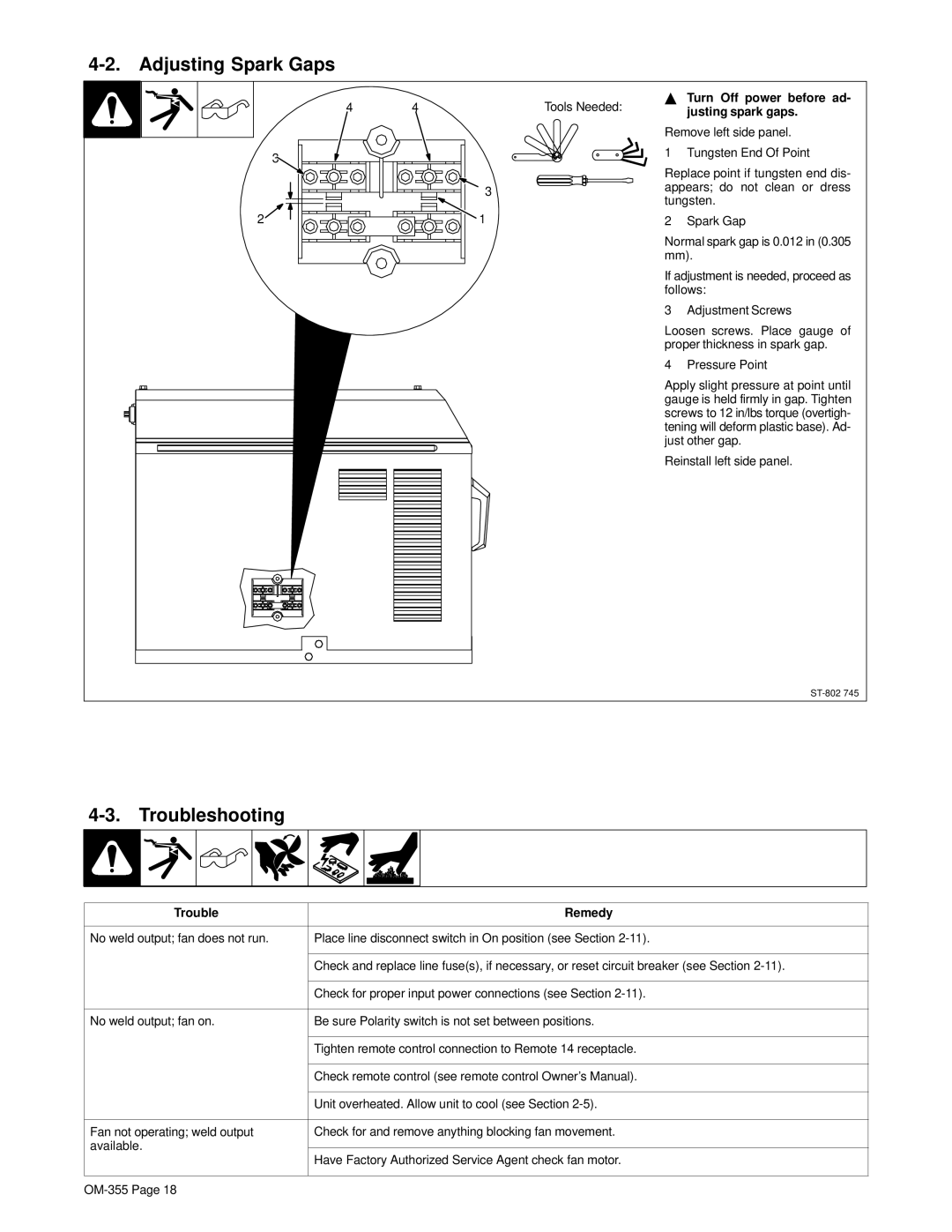

4-2. Adjusting Spark Gaps

4 | 4 |

| Y Turn Off power before ad- | |

| Tools Needed: | justing spark gaps. | ||

|

|

|

| |

|

|

| Remove left side panel. | |

3 |

|

| 1 Tungsten End Of Point | |

|

|

|

| |

|

|

| Replace point if tungsten end dis- | |

|

| 3 | appears; do not clean or dress | |

|

| tungsten. | ||

|

|

| ||

2 |

| 1 | 2 | Spark Gap |

|

|

| Normal spark gap is 0.012 in (0.305 | |

|

|

| mm). | |

|

|

| If adjustment is needed, proceed as | |

|

|

| follows: | |

|

|

| 3 | Adjustment Screws |

|

|

| Loosen screws. Place gauge of | |

|

|

| proper thickness in spark gap. | |

|

|

| 4 | Pressure Point |

|

|

| Apply slight pressure at point until | |

|

|

| gauge is held firmly in gap. Tighten | |

|

|

| screws to 12 in/lbs torque (overtigh- | |

|

|

| tening will deform plastic base). Ad- | |

|

|

| just other gap. | |

Reinstall left side panel.

4-3. Troubleshooting

Trouble | Remedy | |

|

| |

No weld output; fan does not run. | Place line disconnect switch in On position (see Section | |

|

| |

| Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section | |

|

| |

| Check for proper input power connections (see Section | |

|

| |

No weld output; fan on. | Be sure Polarity switch is not set between positions. | |

|

| |

| Tighten remote control connection to Remote 14 receptacle. | |

|

| |

| Check remote control (see remote control Owner’s Manual). | |

|

| |

| Unit overheated. Allow unit to cool (see Section | |

|

| |

Fan not operating; weld output | Check for and remove anything blocking fan movement. | |

available. |

| |

Have Factory Authorized Service Agent check fan motor. | ||

| ||

|

|