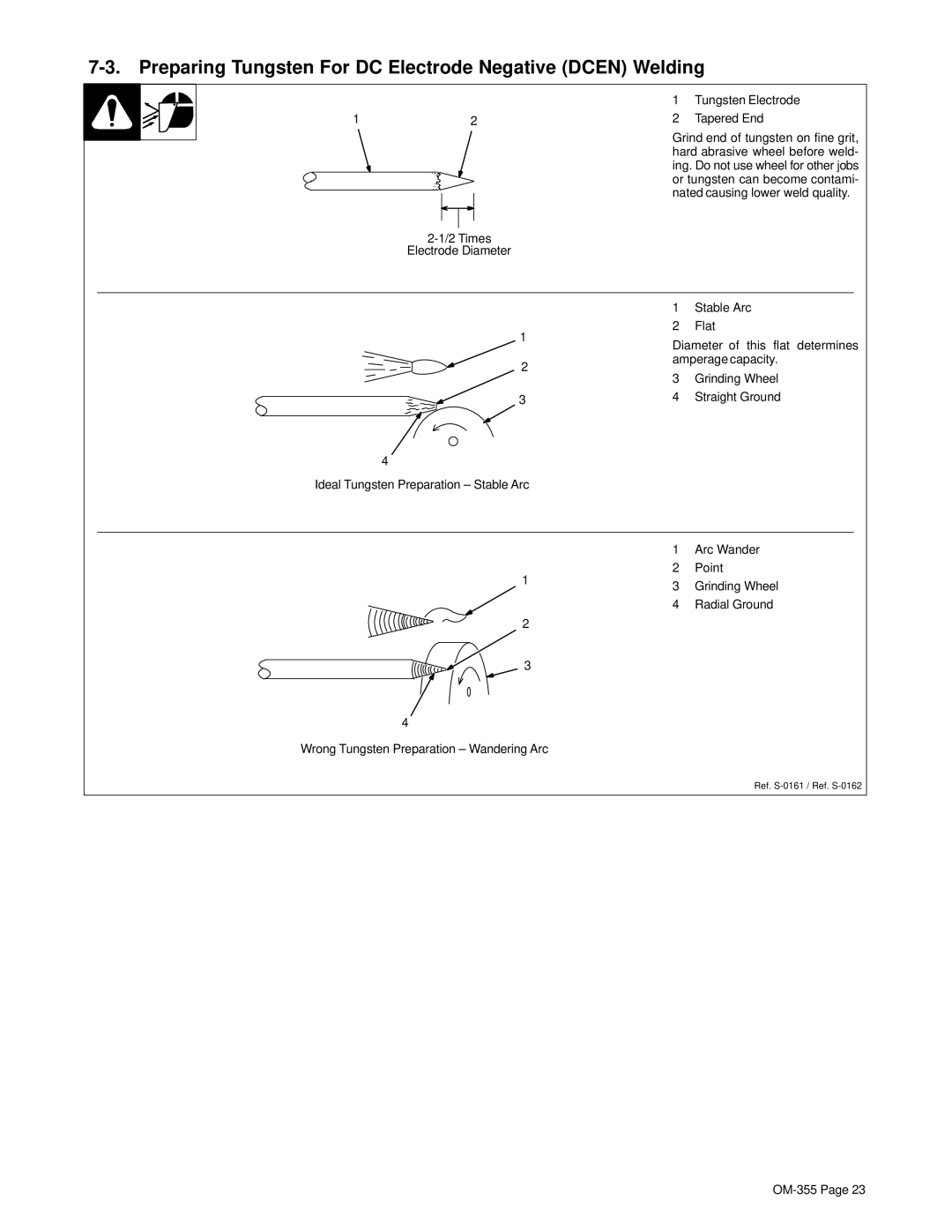

7-3. Preparing Tungsten For DC Electrode Negative (DCEN) Welding

|

| 1 | Tungsten Electrode |

1 | 2 | 2 | Tapered End |

|

| Grind end of tungsten on fine grit, | |

|

| hard abrasive wheel before weld- | |

|

| ing. Do not use wheel for other jobs | |

|

| or tungsten can become contami- | |

|

| nated causing lower weld quality. | |

|

|

| |

| Electrode Diameter |

|

|

|

| 1 | Stable Arc |

| 1 | 2 | Flat |

| Diameter of this flat determines | ||

|

| ||

| 2 | amperage capacity. | |

| 3 | Grinding Wheel | |

|

| ||

| 3 | 4 | Straight Ground |

| 4 |

|

|

Ideal Tungsten Preparation – Stable Arc |

|

| |

|

| 1 | Arc Wander |

| 1 | 2 | Point |

| 3 | Grinding Wheel | |

|

| ||

|

| 4 | Radial Ground |

| 2 |

|

|

| 3 |

|

|

4

Wrong Tungsten Preparation – Wandering Arc

Ref.