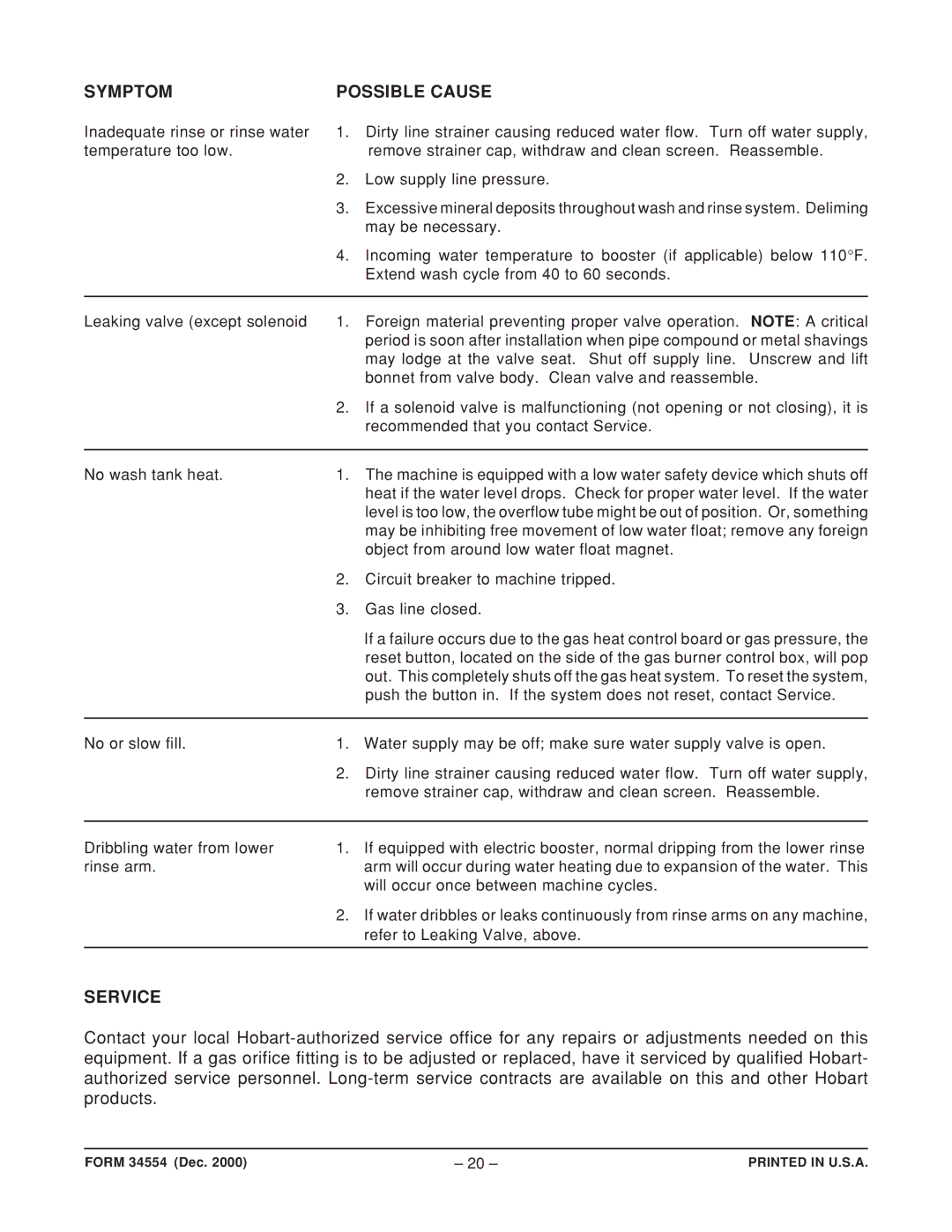

SYMPTOM | POSSIBLE CAUSE |

Inadequate rinse or rinse water temperature too low.

1.Dirty line strainer causing reduced water flow. Turn off water supply, remove strainer cap, withdraw and clean screen. Reassemble.

2.Low supply line pressure.

3.Excessive mineral deposits throughout wash and rinse system. Deliming may be necessary.

4.Incoming water temperature to booster (if applicable) below 110°F. Extend wash cycle from 40 to 60 seconds.

Leaking valve (except solenoid | 1. | Foreign material preventing proper valve operation. NOTE: A critical |

|

| period is soon after installation when pipe compound or metal shavings |

|

| may lodge at the valve seat. Shut off supply line. Unscrew and lift |

|

| bonnet from valve body. Clean valve and reassemble. |

| 2. | If a solenoid valve is malfunctioning (not opening or not closing), it is |

|

| recommended that you contact Service. |

|

|

|

No wash tank heat. | 1. | The machine is equipped with a low water safety device which shuts off |

|

| heat if the water level drops. Check for proper water level. If the water |

|

| level is too low, the overflow tube might be out of position. Or, something |

|

| may be inhibiting free movement of low water float; remove any foreign |

|

| object from around low water float magnet. |

| 2. | Circuit breaker to machine tripped. |

| 3. | Gas line closed. |

|

| If a failure occurs due to the gas heat control board or gas pressure, the |

|

| reset button, located on the side of the gas burner control box, will pop |

|

| out. This completely shuts off the gas heat system. To reset the system, |

|

| push the button in. If the system does not reset, contact Service. |

|

|

|

No or slow fill. | 1. | Water supply may be off; make sure water supply valve is open. |

| 2. | Dirty line strainer causing reduced water flow. Turn off water supply, |

|

| remove strainer cap, withdraw and clean screen. Reassemble. |

|

|

|

Dribbling water from lower | 1. | If equipped with electric booster, normal dripping from the lower rinse |

rinse arm. |

| arm will occur during water heating due to expansion of the water. This |

|

| will occur once between machine cycles. |

| 2. | If water dribbles or leaks continuously from rinse arms on any machine, |

|

| refer to Leaking Valve, above. |

|

|

|

SERVICE

Contact your local

FORM 34554 (Dec. 2000) | – 20 – | PRINTED IN U.S.A. |