FP300 specifications

The Hobart FP300 is a robust and versatile food processor designed to meet the demands of busy commercial kitchens. This unit is known for its efficiency and reliability, making it an essential tool for chefs and food service professionals who prioritize speed and precision in their food preparation tasks.One of the standout features of the Hobart FP300 is its powerful 3/4 horsepower motor, which allows the processor to tackle even the toughest ingredients with ease. This motor provides ample power for slicing, dicing, grating, and chopping, ensuring that food is prepared quickly without compromising on quality. The FP300’s high-speed performance is complemented by its durability, allowing it to withstand the rigors of daily use in high-volume environments.

The Hobart FP300 incorporates advanced technology that enhances its functionality and user experience. It features a 14-inch stainless steel bowl with a capacity to handle large quantities of food, making it ideal for catering events and restaurant kitchens. The bowl's design also facilitates easy cleaning, an essential factor in maintaining hygiene standards in food service operations.

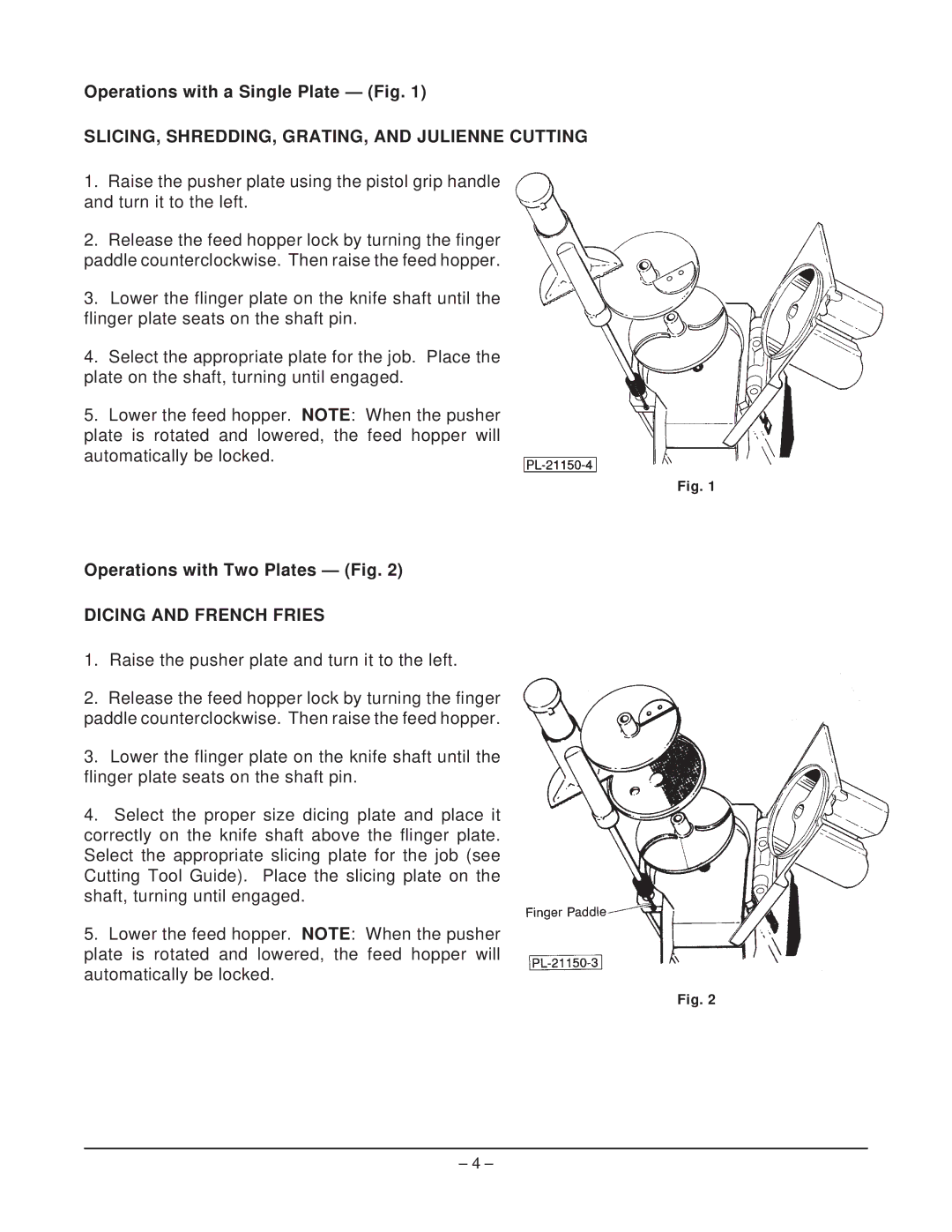

Another key characteristic of the FP300 is its variety of slicing and grating discs, which provide versatility in food preparation. Whether you need julienne vegetables, slice cheese, or grate potatoes, the FP300 has the right attachment to meet your needs. These discs are easily interchangeable, allowing for seamless transitions between different food preparation tasks.

The ergonomic design of the FP300 enhances user comfort and safety. It features a simple control panel with easy-to-use buttons for on, off, and pulse functions, providing greater control over the processing action. Additionally, the processor is designed with safety interlocks that prevent operation unless the bowl is securely in place, ensuring a safe working environment.

Hobart’s commitment to quality is evident in the FP300’s construction. Built with stainless steel and high-grade materials, this food processor is designed to last, resisting corrosion and wear over time. Its compact size allows it to fit on any countertop without compromising workspace, making it an excellent addition to any kitchen setup.

In summary, the Hobart FP300 stands out for its powerful motor, user-friendly design, and versatility in food preparation. Its combination of advanced technology, safety features, and durable construction make it a reliable workhorse for any food service establishment looking to improve efficiency and productivity in the kitchen. Whether you're slicing vegetables, grating cheese, or preparing sauces, the FP300 is designed to handle the job with precision and speed.