SECTION 4 − INSTALLATION

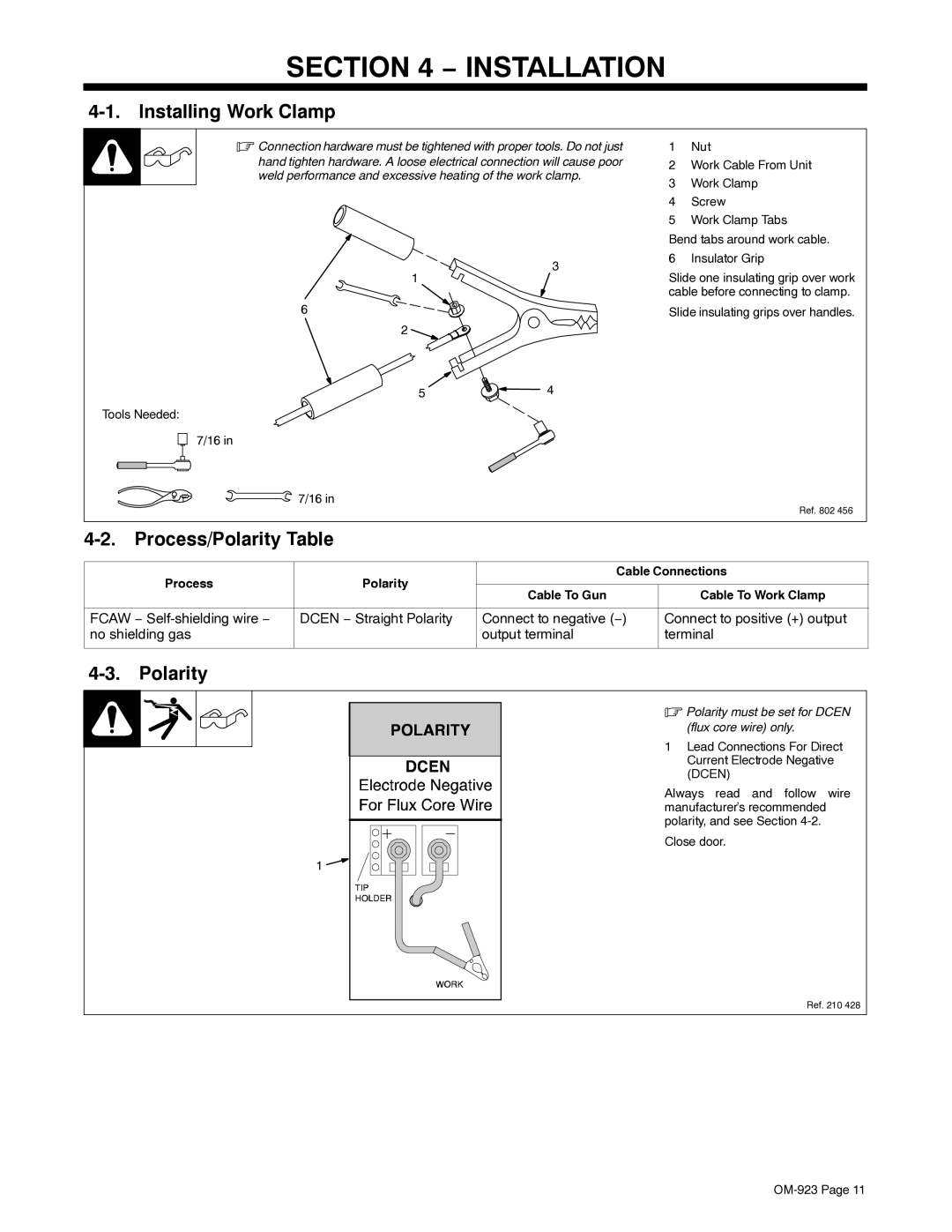

4-1. Installing Work Clamp

. Connection hardware must be tightened with proper tools. Do not just hand tighten hardware. A loose electrical connection will cause poor weld performance and excessive heating of the work clamp.

1Nut

2Work Cable From Unit

3Work Clamp

4Screw

5Work Clamp Tabs

Bend tabs around work cable.

1

3

6 Insulator Grip

Slide one insulating grip over work cable before connecting to clamp.

6![]()

2

5 | 4 |

Tools Needed:

7/16 in

7/16 in

Slide insulating grips over handles.

Ref. 802 456

4-2. Process/Polarity Table

Process | Polarity | Cable Connections | ||

Cable To Gun | Cable To Work Clamp | |||

|

| |||

FCAW − | DCEN − Straight Polarity | Connect to negative (−) | Connect to positive (+) output | |

no shielding gas |

| output terminal | terminal | |

4-3. Polarity

1 ![]()

![]()

.Polarity must be set for DCEN (flux core wire) only.

1Lead Connections For Direct Current Electrode Negative (DCEN)

Always read and follow wire manufacturer’s recommended polarity, and see Section

Close door.

Ref. 210 428