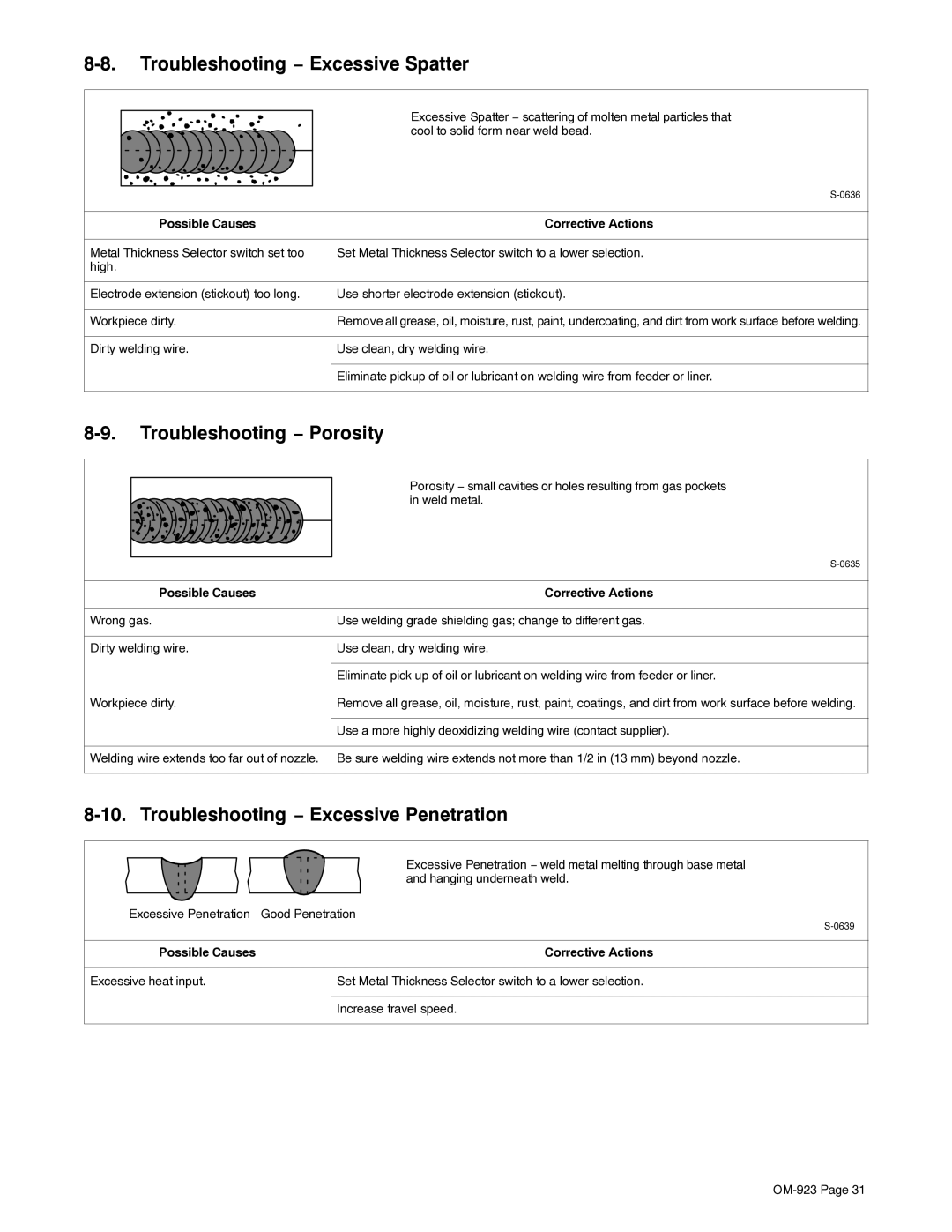

Troubleshooting − Excessive Spatter | ||

|

| Excessive Spatter − scattering of molten metal particles that |

|

| cool to solid form near weld bead. |

|

| |

| Possible Causes | Corrective Actions |

Metal Thickness Selector switch set too | Set Metal Thickness Selector switch to a lower selection. | |

high. |

|

|

Electrode extension (stickout) too long. | Use shorter electrode extension (stickout). | |

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, undercoating, and dirt from work surface before welding. | |

Dirty welding wire. | Use clean, dry welding wire. | |

|

| Eliminate pickup of oil or lubricant on welding wire from feeder or liner. |

8-9. Troubleshooting − Porosity

| Porosity − small cavities or holes resulting from gas pockets |

| in weld metal. |

| |

Possible Causes | Corrective Actions |

Wrong gas. | Use welding grade shielding gas; change to different gas. |

Dirty welding wire. | Use clean, dry welding wire. |

| Eliminate pick up of oil or lubricant on welding wire from feeder or liner. |

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, coatings, and dirt from work surface before welding. |

| Use a more highly deoxidizing welding wire (contact supplier). |

Welding wire extends too far out of nozzle. | Be sure welding wire extends not more than 1/2 in (13 mm) beyond nozzle. |

| |

| Excessive Penetration − weld metal melting through base metal |

| and hanging underneath weld. |

Excessive Penetration Good Penetration | |

| |

Possible Causes | Corrective Actions |

Excessive heat input. | Set Metal Thickness Selector switch to a lower selection. |

| Increase travel speed. |