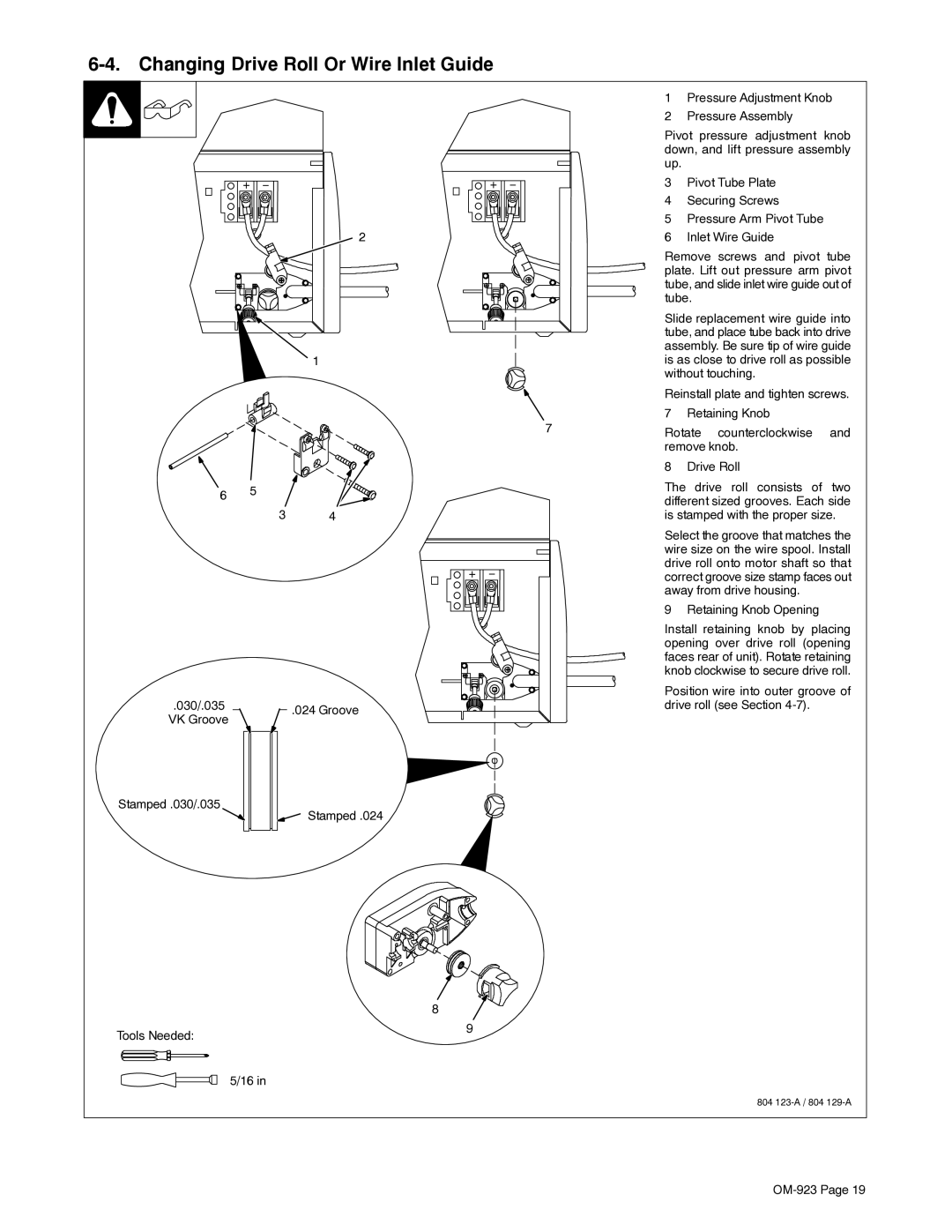

6-4. Changing Drive Roll Or Wire Inlet Guide

+ −

6 5

.030/.035 VK Groove

Stamped .030/.035

Tools Needed:

5/16 in

1 Pressure Adjustment Knob

2 Pressure Assembly

Pivot pressure adjustment knob down, and lift pressure assembly up.

| + − |

| 3 | Pivot Tube Plate |

|

|

| 4 | Securing Screws |

|

|

| 5 Pressure Arm Pivot Tube | |

| 2 |

| 6 | Inlet Wire Guide |

|

|

| Remove screws and pivot tube | |

|

|

| plate. Lift out pressure arm pivot | |

|

|

| tube, and slide inlet wire guide out of | |

|

|

| tube. | |

|

|

| Slide replacement wire guide into | |

|

|

| tube, and place tube back into drive | |

|

|

| assembly. Be sure tip of wire guide | |

| 1 |

| is as close to drive roll as possible | |

|

|

| without touching. | |

|

|

| Reinstall plate and tighten screws. | |

|

| 7 | 7 | Retaining Knob |

|

| Rotate counterclockwise and | ||

|

|

| ||

|

|

| remove knob. | |

|

|

| 8 | Drive Roll |

|

|

| The drive roll consists of two | |

|

|

| different sized grooves. Each side | |

3 | 4 |

| is stamped with the proper size. | |

|

|

| Select the groove that matches the | |

|

|

| wire size on the wire spool. Install | |

| + − |

| drive roll onto motor shaft so that | |

|

| correct groove size stamp faces out | ||

|

|

| away from drive housing. | |

|

|

| 9 | Retaining Knob Opening |

|

|

| Install retaining knob by placing | |

|

|

| opening over drive roll (opening | |

|

|

| faces rear of unit). Rotate retaining | |

|

|

| knob clockwise to secure drive roll. | |

|

|

| Position wire into outer groove of | |

| .024 Groove |

| drive roll (see Section | |

|

|

|

| |

Stamped .024

8![]()

9

804