ML-110974, AM14TC, AM14T, AM14F, ML-110973 specifications

Hobart ML-110975, ML-110973, AM14F, AM14T, and AM14TC are a series of advanced models designed for commercial food preparation, offering efficiency and longevity in professional kitchens. Each model is tailored to meet diverse culinary needs, making them a valuable addition to any foodservice operation.Starting with the Hobart ML-110975 and ML-110973, these models are known for their robust build and high performance. The ML-110975 features a powerful motor and a durable construction, enabling it to handle heavy mixing tasks seamlessly. This model is equipped with a 12-quart bowl, making it suitable for a variety of batch sizes. On the other hand, the ML-110973 offers a slightly smaller 7-quart capacity, making it ideal for establishments with lower volume requirements. Both models utilize a unique planetary mixing action that ensures thorough mixing of ingredients, thus enhancing the quality of the final product.

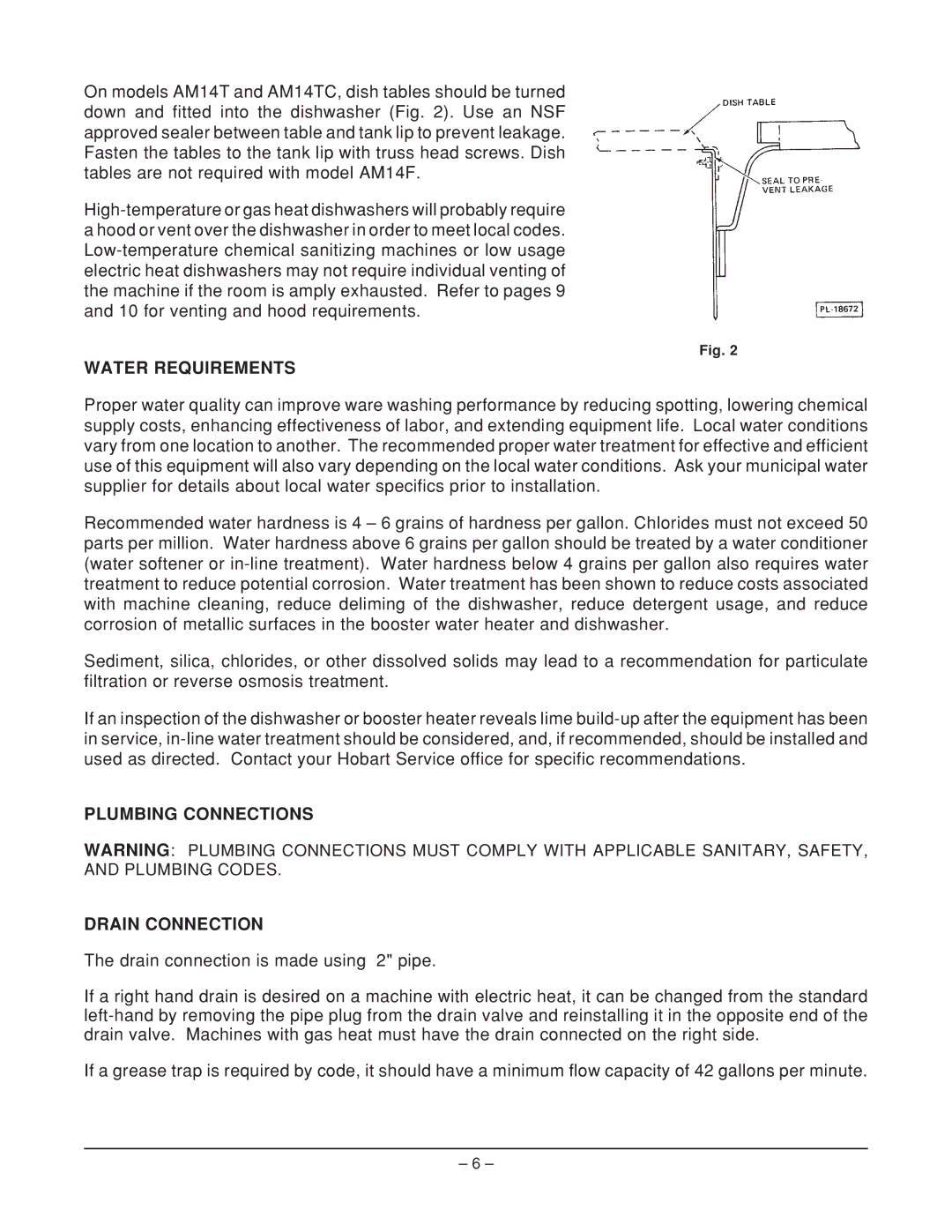

The AM14F and AM14T models take the capabilities of the Hobart lineup even further. The AM14F features a food processor attachment that expands its functionality beyond just mixing, allowing for tasks like chopping and grating, making it an essential tool for chefs looking to maximize efficiency. The AM14T includes additional temperature control features, making it particularly useful in recipes that require precise temperature management for ingredients, such as chocolate or delicate sauces.

Finally, the AM14TC integrates innovative technology into its design. This model comes with a time and temperature control display that provides added precision during the preparation process. The touchscreen interface simplifies operation, allowing chefs to easily program settings based on specific recipes. This not only enhances the consistency of food preparation but also minimizes the potential for human error.

Across this series, all models utilize Hobart's commitment to quality and innovation, combining solid construction, powerful motors, and user-friendly features. With their ability to accommodate a wide range of culinary tasks, from dough mixing to food processing, Hobart's ML-110975, ML-110973, AM14F, AM14T, and AM14TC are indispensable tools for any professional kitchen aiming to improve productivity and efficiency. Their reliable performance and versatility ensure that they can keep pace with the demands of any high-volume foodservice establishment. With Hobart’s reputation for excellence, these models are a worthwhile investment for chefs and foodservice operators alike.