9-14. Troubleshooting − Burn-Through

Possible Causes | Corrective Actions |

|

|

Excessive heat input. | Select lower voltage range and reduce wire feed speed. |

|

|

| Increase and/or maintain steady travel speed. |

|

|

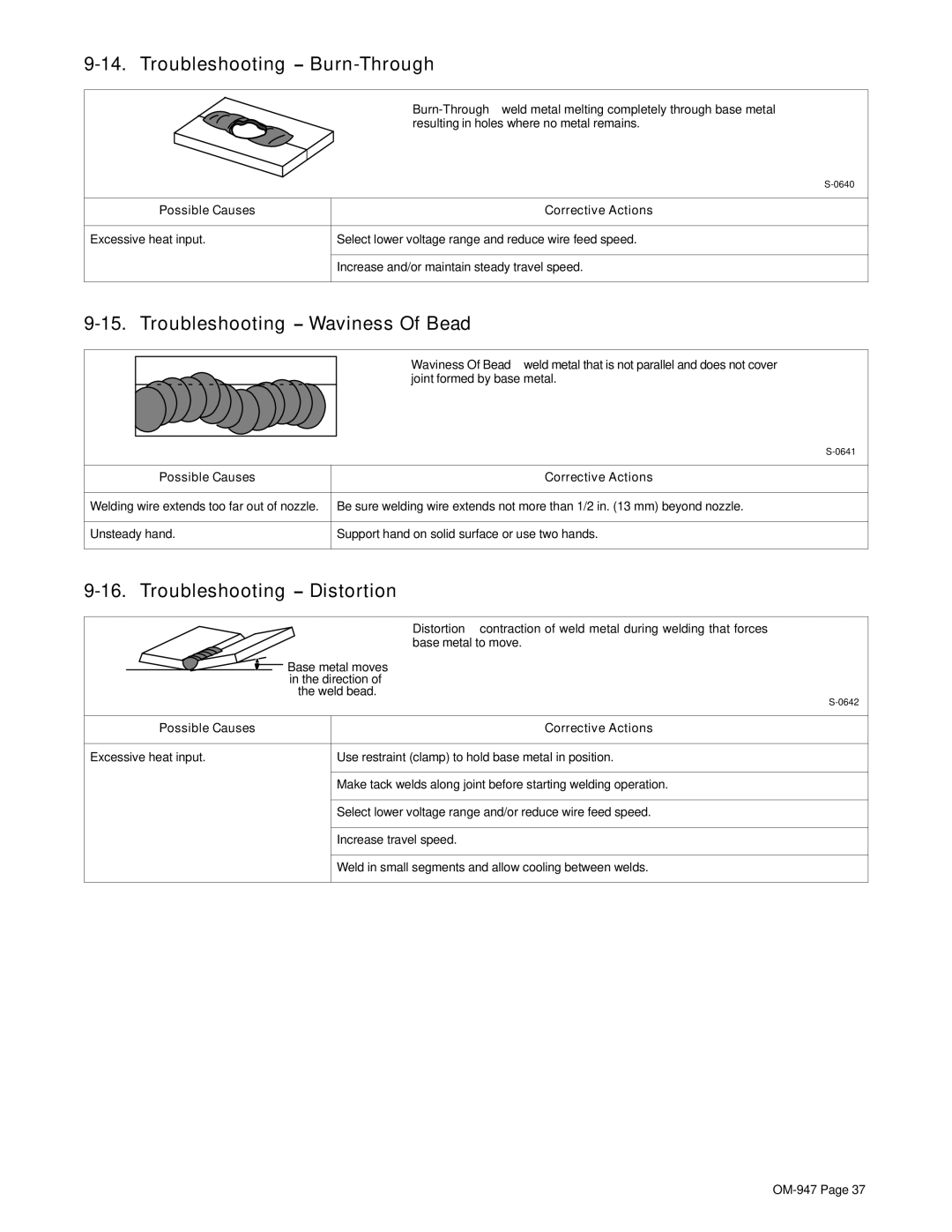

9-15. Troubleshooting − Waviness Of Bead

Waviness Of Bead − weld metal that is not parallel and does not cover joint formed by base metal.

Possible Causes | Corrective Actions |

|

|

Welding wire extends too far out of nozzle. | Be sure welding wire extends not more than 1/2 in. (13 mm) beyond nozzle. |

|

|

Unsteady hand. | Support hand on solid surface or use two hands. |

|

|

9-16. Troubleshooting − Distortion

|

|

|

|

| Distortion − contraction of weld metal during welding that forces |

|

|

|

|

| base metal to move. |

|

|

|

| Base metal moves | |

|

|

| |||

|

|

|

| ||

|

|

|

| in the direction of | |

|

|

|

| the weld bead. | |

|

|

|

|

| |

|

|

|

|

| |

| Possible Causes |

|

| Corrective Actions | |

|

|

|

| ||

Excessive heat input. |

|

| Use restraint (clamp) to hold base metal in position. | ||

|

|

|

|

|

|

|

|

|

|

| Make tack welds along joint before starting welding operation. |

|

|

|

|

|

|

|

|

|

|

| Select lower voltage range and/or reduce wire feed speed. |

|

|

|

|

|

|

|

|

|

|

| Increase travel speed. |

|

|

|

|

|

|

|

|

|

|

| Weld in small segments and allow cooling between welds. |

|

|

|

|

|

|